Abstract

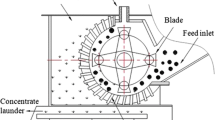

Indium components have been successfully recovered from indium-containing scrap powders collected by the sand-blasting of sputtering chamber walls. A two-step air-classifier was used for the classification of the scrap powder. The raw scrap powders containing 10 wt% indium were classified into 12 lots according to the revolutions per minute of a classifying wheel: 6,000, 8,000, 10,000, and 12,000 rpm. The enrichment of indium component was possible in fine overflow fraction, that is, the third classified fractions at all wheel speeds, while the indium components were not concentrated in the first classified fraction. The grade of the indium components became higher with decreasing particle size and the highest grade was obtained in the third classified fraction. The purity of the indium component improved to 17.4 wt% and the recovery of the indium component was in the range 94.2–96.2% for the second and third classified fractions. The recovery and enrichment of indium should be optimized for the maximum recycling of the indium components, which can be used as raw materials in the subsequent electro-refining processes.

Similar content being viewed by others

References

S. Pickering, III-Vs Rev. 12, 42–44 (1999)

S.-J. Hsieh, C.-C. Chen, W.C. Say, Mater. Sci. Eng. B 158, 82–87 (2009)

S. Venetskii, Metallurgist 15, 148–150 (1971)

W. Wang, W. Zhu, L. Zhang, Res. Chem. Intermed. 35, 761–767 (2009)

Z. Xu, G. Ding, G. Zhong, G. Xing, F. Li, W. Huang, H. Tian, Res. Chem. Intermed. 34, 249–256 (2008)

S. Matthews, W. De Bosscher, A. Blondeel, J. Van Holsbeke, H. Delrue, Vacuum 83, 518–521 (2009)

A.M. Alfantazi, R.R. Moskalyk, Miner. Eng. 16, 687–694 (2003)

B. Gupta, N. Mudhar, I. Singh, Sep. Purif. Technol. 57, 294–303 (2007)

Acknowledgment

The present research was supported by the Ministry of Knowledge Economy (MKE), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hong, H.S., Jung, H. & Hong, SJ. Recycling of the indium scrap from ITO sputtering waste. Res Chem Intermed 36, 761–766 (2010). https://doi.org/10.1007/s11164-010-0179-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-010-0179-5