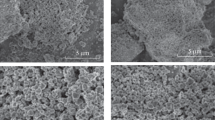

Results are provided for a study of sintering and some properties of new SiC-sintered polycrystalline and SiC-composite materials. Materials are prepared by sintering silicon carbide nano- and micropowders in high-pressure equipment. SiC powders are used both in pure form and with titanium compound nanocoatings applied to them.

Similar content being viewed by others

References

A. V. Ragulya, “Consolidation of ceramic nanopowders,” Advances in Applied Ceramics, 10(3), 118 – 134 (2008).

N. Korableva, V. Rumyantsev, N. Kovelenov, et al., “Consolidation of ceramic composite materials in the TiN–TiB2 system,” Euro PM2011 Congress Proceedings: Euro PM2011 Congress and Exhibition. Barcelona, 1, 183 – 188 (2011).

V. Rumyantsev, A. Osmakov, N. Korableva, et al., “Tool ceramics based on nanosized Si3N4 powders,” Proc. World Powder Metallurgy Congress and Exhibition PM2010, Florence, 3, 591 – 595 (2010)

N. V. Novikov (editor), Synthesis of Ultrahard Materials, in 3 Vol., Vol. 2, Composite Tool Ultrahard Materials [in Russian], Naukova Dumka, Kiev (1986).

A. A. Shul’zhenko, V. G. Gargin, V. A. Shishkin, et al., Polycrystalline Materials Based on Diamond (N. V. Novikov, editor) [in Russian], Naukova Dumka, Kiev (1989).

A. A. Shul’zhenko, S. A. Bozhko, A. N. Sokolov, et al., Synthesis, Sintering and Properties of Cubic Boron Nitride (N. V. Novikov, editor), Naukova Dumka, Kiev (1993).

V. V. Rudneva, “Physicochemical certification of nanosize silicon carbide powder,” Izv. Vyssh. Uchebn. Zaved. Chern. Met., No. 5, 20 – 22 (2006).

V. V. Rudneva, “Improvement of plasma-metal technology for producing silicon carbide nanopowder,” Author’s Abstr. Diss. Doct. Tech. Sci., Novokuznetsk (2009).

V. V. Rudnev, G. V. Galevskii, and E. K Yurkova, “Study of silicon carbide nanopowder morphology and particle size using electron microscopy,” Poroshk. Metall. Funkts. Pokrytiya, No. 3, 32 – 37 (2009).

A. P. Garshin and S. M. Fedotova, Abrasive Materials and Tools. Production Technology [in Russian], Izd. Politekhn. Univ., St. Petersburg (2008).

S. P. Bogdanov, Powder coating preparation based on an ion transport method,” Fiz. Khim. Stekla., 37(2), 229 – 237 (2011).

S. P. Bogdanov, “Iodine transport method for preparing coatings on powders,” Izv. SPbGTI, 16(42), 24 – 28 (2012).

S. P. Bogdanov, “Role of graphite-like boron nitride particle size during nucleation of cubic boron nitride,” Fiz. Khim. Stekla., 34(2), 274 – 280 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 2, pp. 23 – 28, February 2015.

Rights and permissions

About this article

Cite this article

Bogdanov, S.P., Garshin, A.P., Korableva, N.Y. et al. Study of Sintering Polycrystalline and Composite Materials Based on Silicon Carbide in High-Pressure Equipment. Refract Ind Ceram 56, 66–71 (2015). https://doi.org/10.1007/s11148-015-9785-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-015-9785-5