Abstract

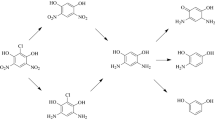

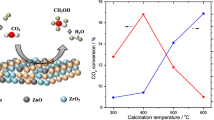

CdO and co-precipitation CdAl2O4 (PreCdAl2O4) catalysts were prepared and used in the isomerization reaction of dipotassium 1,8-naphthalenedicarboxylate. The catalyst samples were characterized by X-ray powder diffraction, scanning electron microscopy, inductively coupled plasma, nitrogen physical adsorption, Fourier transform infrared, X-ray photoelectron spectrum and NH3-temperature programmed desorption. The results reveal that the crystal structure of all samples is almost unchanged. However, compared with CdO, the PreCdAl2O4 catalysts exhibit a smaller particle size and stronger acid. This feature may be attributed to the fact that a small amount of Al atoms are introduced into the catalyst structure in the synthesis process of CdAl2O4 by co-precipitation method. Furthermore, the effects of different catalyst, calcination temperature of catalyst, Cd/Al molar ratio of PreCdAl2O4 catalysts and reaction temperature on the isomerization reaction were investigated. The experimental results show that the optative catalyst was PreCdAl2O4-0.95 of calcination at 673 K. Meanwhile, a dipotassium 2,6-naphthalenedicarboxylate selectivity of 90.6 % and dipotassium 1,8-naphthalenedicarboxylate conversion of 98.0 % was obtained when this reaction was carried out at 723 K for 2 h in 1.5 MPa CO2 atmosphere.

Similar content being viewed by others

References

Lillwitz LD (2001) Production of dimethyl-2,6-naphthalenedicarboxylate: precursor to polyethylene naphthalate. Appl Catal A 221:337–358

Shiraishi Y, Toshima N (1999) Colloidal silver catalysts for oxidation of ethylene. J Mol Catal A 141:187–192

Hardy L, Stevenson I, Fritz A, Boiteux G, Seytre G, Schönhals A (2003) Dielectric and dynamic mechanical relaxation behaviour of poly(ethylene 2,6-naphthalene dicarboxylate). II. Semicrystalline oriented films. Polymer 44:4311–4323

Yuan B, Li ZS, Liu YJ, Zhang SS (2008) Liquid phase acylation of 2-methylnaphthalene catalyzed by H-beta zeolite. J Mol Catal A 280:210–218

Roupakias CP, Bikiaris DN, Karayannidis GP (2005) Synthesis, thermal characterization, and tensile properties of alipharomatic polyesters derived from 1,3-propanediol and terephthalic, isophthalic, and 2,6-naphthalenedicarboxylic acid. J Polym Sci Pol Chem 43:3998–4011

Guo MM, Brittain WJ (1998) Structure and properties of naphthalene containing polyesters, 4. new insight into the relationship of transesterification and miscibility. Macromolecules 31:7166–7171

Ishiharada M, Hayashi M, Saito S (1986) Electrical conduction in poly(ethylene-2,6-naphthalate) films of varying crystallinity. Polymer 27:349–352

Zhang H, Wu J, Zhang J, He JS (2005) 1-allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Kim SH, Kang SW, Park JK, Park YH (1998) Effect of composition and molecular structure on the LC phase of PHB–PEN–PET ternary blend. J Appl Polym Sci 70:1065–1073

Buchner S, Wiswe D, Zachmann HG (1989) Kinetics of crystallization and melting behaviour of poly(ethylene naphthalene-2,6-dicarboxylate). Polymer 30:480–488

Miller M, Macdonald WA, Adam R (2012) Adhesion of UV-cured laminates of poly(ethylene-2,6-naphthalate) (PEN) and poly(ethylene terephthalate) (PET) films. J Adhes Sci Technol 26:55–78

Yang P, Tian FQ, Ohki Y (2014) Dielectric properties of poly(ethylene terephthalate) and poly(ethylene 2, 6-naphthalate). IEEE Trans Dielectr Electr Insul 21:2310–2317

Mourey TH, Slater LA, Galipo RC, Janes DL, Moody RE (2012) Size-exclusion chromatography of poly(ethylene 2,6-naphthalate). J Chromatogr A 1256:129–135

Sonnauer A, Hoffmann F, FrÖba M, Kienle L, Duppel V, Thommes M, Serre C, Férey G, Stock N (2009) Giant pores in a chromium 2,6-naphthalenedicarboxylate open-framework structure with MIL-101 topology. Angew Chem 121:3791–3794

Heininger C, Kampschulte L, Heckl WM, Lackinger M (2009) Distinct differences in self-assembly of aromatic linear dicarboxylic acids. Langmuir 25:968–972

Dinca M, Long JR (2005) Strong H2 binding and selective gas adsorption within the microporous coordination solid Mg3(O2C-C10H6-CO2)3. J Am Chem Soc 127:9376–9377

Takeuchi G, Shimoura Y, Hara T (1996) Selective transalkylation of naphthalene and ethylnaphthalene over solid acid catalysts. Catal Lett 41:195–197

Fujishiro K, Mitamura S (1989) The zinc(II)-catalyzed Henkel reaction of dipotassium 1,8-naphthalenedicarboxylate in a dispersion medium. Bull Chem Soc Jpn 62:786–790

Khlestkin RN, Davydov AA, Khlestkina VL, Efremov AA (1980) Investigation of catalysts for thermal conversion of alkaline salts of benzenecarboxylic acids. Reac Kinet Catal Lett 14:105–111

Diaz Z, Brownscombe TF (2002) Method for increasing the yield of 2,6-NDA. US Patent 6,426,431. 30 Jul 2002

Wu ZB, Tang N, Xiao L, Liu Y, Wang HQ (2010) MnOx/TiO2 composite nanoxides synthesized by deposition-precipitation method as a superior catalyst for NO oxidation. J Colloid Interface Sci 352:143–148

Haq IU, Akhtar K (2000) Preparation and characterization of uniform coated particles (Cobalt compounds on cadmium compounds). J Mater Sci 35:2565–2571

Okumura M, Masuyama N, Konishi E, Ichikawa S, Akita T (2002) CO oxidation below room temperature over Ir/TiO2 catalyst prepared by deposition precipitation method. J Catal 208:485–489

Dakhel AA (2011) Structural, optical and electrical measurements on boron-doped CdO thin films. J Mater Sci 46:6925–6931

Wang WS, Zhen L, Xu CY, Shao WZ (2008) Aqueous solution synthesis of Cd(OH)2 hollow microspheres via ostwald ripening and their conversion to CdO hollow microspheres. J Phys Chem C 112:14360–14366

Verma S, Pandey SK, Gupta M, Mukherjee S (2014) Influence of ion-beam sputtering deposition parameters on highly photosensitive and transparent CdZnO thin films. J Mater Sci 49:6917–6929

Moholkar AV, Agawane GL, Sim K, Kwon Y, Choi DS, Rajpure KY, Kim JH (2010) Temperature dependent structural, luminescent and XPS studies of CdO: Ga thin films deposited by spray pyrolysis. J Alloys Compd 506:794–799

Gulino A, Castelli F, Dapporto P, Rossi P, Fragala I (2002) Synthesis and characterization of liquid MOCVD precursors for thin films of cadmium oxide. Chem Mater 14:4955–4962

Tadjarodi A, Imani M (2011) Synthesis and characterization of CdO nanocrystalline structure by mechanochemical method. Mater Lett 65:1025–1027

Askarinejad A, Morsali A (2008) Syntheses and characterization of CdCO3 and CdO nanoparticles by using a sonochemical method. Mater Lett 62:478–482

Bazargan AM, Fateminia SMA, Ganji ME, Bahrevar MA (2009) Bahrevar, Electrospinning preparation and characterization of cadmium oxide nanofibers. Chem Eng J 155:523–527

Li XL, Li YH (2014) Molybdenum modified CeAlOx catalyst for the selective catalytic reduction of NO with NH3. J Mol Catal A 386:69–77

Wang L, Li W, Qi GS, Weng D (2012) Location and nature of Cu species in Cu/SAPO-34 for selective catalytic reduction of NO with NH3. J Catal 289:21–29

Seol G, Jeong HS (1996) Skeletal isomerization of 1-butene over ferrierite and ZSM-5 zeolites: influence of zeolite acidity. Catal Lett 36:249–253

Pines H, Haag WO (1960) Alumina: catalyst and support. I. Alumina, its intrinsic acidity and catalytic activity. J Am Chem Soc 82:2471–2483

Oliveira KD, Santana RC, Ávila-Neto CN, Cardoso D (2015) Isomerization of n-hexane with Pt/Ni-based catalysts supported on Al-rich zeolite beta and correlation with acidity and oxidation state of metal crystallites. Appl Catal A 495:173–183

McNelis E (1965) Reactions of aromatic carboxylates. II. the Henkel reaction. J Org Chem 30:1209–1213

Acknowledgments

This work is supported by the Ph.D. Starting Foundation of Jiangxi Agricultural University (09004712) and Jiangxi Provincial Department of Education Fund (GJJ150432).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, G., Wang, W., Cai, L. et al. A high performance co-precipitation CdAl2O4 catalyst for the isomerization of dipotassium 1,8-naphthalenedicarboxylate. Reac Kinet Mech Cat 119, 523–535 (2016). https://doi.org/10.1007/s11144-016-1071-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-016-1071-0