Abstract

Purpose

To understand the mechanism of spherical microparticle formation during lyophilizing a tert-Butyl alcohol (TBA)/water solution of a zinc peptide adduct.

Method

A small peptide, PC-1, as well as zinc PC-1 at (3:2) and (3:1) ratios, were dissolved in 44% (wt.%) of TBA/water, gradually frozen to −50°C over 2 h (“typical freezing step”), annealed at −20°C for 6 h (“annealing step”), and subsequently lyophilized with primary and secondary drying. Zinc peptide (3:1) lyophile was also prepared with quench cooling instead of the typical freezing step, or without the annealing step. Other TBA concentrations, i.e., 25%, 35%, 54% and 65%, were used to make the zinc peptide (3:1) adduct lyophile with the typical freezing and annealing steps. The obtained lyophile was analyzed by Scanning Electron Microscopy (SEM). The zinc peptide solutions in TBA/water were analyzed by Differential Scanning Calorimeter (DSC). The surface tension of the TBA/water co-solvent system was measured by a pendant drop shape method.

Results

With typical freezing and annealing steps, the free peptide lyophile showed porous network-like structure that is commonly seen in lyophilized products. However, with increasing the zinc to peptide ratio, uniform particles were gradually evolved. Zinc peptide (3:1) adduct lyophiles obtained from 25%, 35% and 44% TBA exhibit a distinctive morphology of uniform and spherical microparticles with diameters of ∼3–4 μm, and the spherical zinc peptide particles are more predominant when the TBA level approaches 20%. Adopting quench cooling in the lyophilization cycle leads to irregular shape fine powders, and eliminating the annealing step causes rough particles surface. When TBA concentration increases above 54%, the lyophiles demonstrate primarily irregular shape particles.

Conclusions

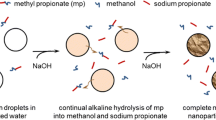

A proposed mechanism of spherical particle formation of the 3:1 zinc peptide encompasses the freezing of a TBA/water solution (20–70% TBA) causing the formation of a TBA hydrate phase (“dispersed TBA hydrate”). Decreasing the temperature further causes the formation of a eutectic mixture between TBA hydrate (“eutectic TBA hydrate”) and water. Due to its low aqueous solubility, the zinc peptide adduct accumulates in both of the dispersed and eutectic TBA hydrate phases to form a hydrophobic “oil” phase. Since the eutectic TBA hydrate phase is surrounded by ice, a “solid emulsion” forms to lower the interfacial energy, and gives rise to spherical zinc peptide particles upon solvent sublimation. Possibility of liquid–liquid phase separation during freeze-drying was also investigated, and no evidence was found to support this alternative mechanism.

Similar content being viewed by others

References

S. L. Nail, S. Jiang, S. Chongprasert, and S. A. Knopp. Fundamentals of freeze-drying. Pharm. Biotechnol. 14:281–360 (2002).

N. A. Williams and G. P. Polli. The lyophilization of pharmaceuticals: a literature review. J. Parenter. Sci. Technol. 38(2):48–59 (1984).

N. Ni, M. Tesconi, S. E. Tabibi, S. Gupta, and S. H. Yalkowsky. Use of pure t-butanol as a solvent for freeze-drying: a case study. Int. J. Pharm. 226(1–2):39–46 (2001) Medline. DOI 10.1016/S0378-5173(01)00757-8.

D. W. Flamberg, D. L. Francis, S. L. Morgan, and G. F. Wickes. Low temperature vacuum drying of sterile parenterals from ethanol. Bull. Parenter. Drug. Assoc. 24(5):209–217 (1970).

D. L. Teagarden and D. S. Baker. Practical aspects of lyophilization using non-aqueous co-solvent systems. Eur. J. Pharm. Sci. 15(2):115–133 (2002) Medline, DOI 10.1016/S0928-0987(01)00221-4.

K. Kasraian and P. P. DeLuca. The effect of tertiary butyl alcohol on the resistance of the dry product layer during primary drying. Pharm. Res. 12(4):491–495 (1995) Medline, DOI 10.1023/A:1016285425670.

J. Oesterle, F. Franks, and T. Auffret. The influence of tertiary butyl alcohol and volatile salts on the sublimation of ice from frozen sucrose solutions: implications for freeze-drying. Pharm. Dev. Technol. 3(2):175–183 (1998) Medline, DOI 10.3109/10837459809028493.

C. Telang and R. Suryanarayanan. Crystallization of cephalothin sodium during lyophilization from tert-butyl alcohol–water cosolvent system. Pharm Res. 22(1):153–160 (2005) Medline, DOI 10.1007/s11095-004-9021-3.

D. J. Van Drooge, W. L. Hinrichs, and H. W. Frijlink. Incorporation of lipophilic drugs in sugar glasses by lyophilization using a mixture of water and tertiary butyl alcohol as solvent. J. Pharm. Sci. 93(3):713–725 (2004) Medline, DOI 10.1002/jps.10590.

Z. Wang, Y. Deng, and X. Zhang. The novel application of tertiary butyl alcohol in the preparation of hydrophobic drug–HPbetaCD complex. J. Pharm. Pharmacol. 58(3):409–414 (2006) Medline, DOI 10.1211/jpp.58.3.0017.

J. Cui, C. Li, Y. Deng, Y. Wang, and W. Wang. Freeze-drying of liposomes using tertiary butyl alcohol/water cosolvent systems. Int. J. Pharm. 312(1–2):131–136 (2006) Medline, DOI 10.1016/j.ijpharm.2006.01.004.

S. Wittaya-Areekul, G. F. Needham, N. Milton, M. L. Roy, and S. L. Nail. Freeze-drying of tert-butanol/water cosolvent systems: a case report on formation of a friable freeze-dried powder of tobramycin sulfate. J. Pharm. Sci. 91(4):1147–1155 (2002) Medline, DOI 10.1002/jps.10113.

Y. Koyama, M. Kamat, R. J. De Angelis, R. Srinivasan, and P. P. DeLuca. Effect of solvent addition and thermal treatment on freeze drying of cefazolin sodium. J. Parenter. Sci. Technol. 42(2):47–52 (1988).

M. J. Pikal, A. L. Lukes, J. E. Lang, and K. Gaines. Quantitative crystallinity determinations for beta-lactam antibiotics by solution calorimetry: correlations with stability. J. Pharm. Sci. 67(6):767–773 (1978) Medline, DOI 10.1002/jps.2600670609.

M. J. Pikal, A. L. Lukes, and J. E. Lang. Thermal decomposition of amorphous beta-lactam antibacterials. J. Pharm. Sci. 66(9):1312–1316 (1977) Medline, DOI 10.1002/jps.2600660927.

K. Kasraian and P. P. DeLuca. Thermal analysis of the tertiary butyl alcohol–water system and its implications on freeze-drying. Pharm. Res. 12(4):484–490 (1995) Medline, DOI 10.1023/A:1016233408831.

K. A. Jackson and J. D. Hunt. Lamellar and rod eutectic growth. Trans. Metall. Soc. AIME. 236:1129–1142 (1966).

A. Martin. Physical Pharmacy. Lippincott Williams & Wilkins, Baltimore, MD, 1993, pp. 362–368.

M. C. Heller, J. F. Carpenter, and T. W. Randolph. Effects of phase separating systems on lyophilized hemoglobin. J. Pharm. Sci. 85:1358–1362 (1996) Medline, DOI 10.1021/js960019t.

M. C. Heller, J. F. Carpenter, and T. W. Randolph. Manipulation of lyophilization-induced phase separation: implications for pharmaceutical proteins. Biotechnol. Prog. 13:590–596 (1997) Medline, DOI 10.1021/bp970081b.

M. C. Heller, J. F. Carpenter, and T. W. Randolph. Protein formulation and lyophilization cycle design: prevention of damage due to freeze-concentration induced phase separation. Biotechnol. Bioeng. 63:166–174 (1999) Medline, DOI 10.1002/(SICI)1097-0290(19990420)63:2<166::AID-BIT5>3.0.CO;2-H.

M. C. Heller, J. F. Carpenter, and T. W. Randolph. Conformational stability of lyophilized PEGylated proteins in a phase-separating system. J. Pharm. Sci. 88:58–64 (1999) Medline, DOI 10.1021/js980257j.

F. Franks. Freeze-drying: from empiricism to predictability. The significance of glass transitions. Dev. Biol. Stand. 74:9–18 (1992).

F. Franks. Freeze-drying: a combination of physics, chemistry, engineering and economics. Jpn. J. Freezing Drying. 38:5–16 (1992).

R. H. Hatley and A. Mant. Determination of the unfrozen water content of maximally freeze-concentrated carbohydrate solutions. Int. J. Biol. Macromol. 15:227–232 (1993) Medline, DOI 10.1016/0141-8130(93)90042-K.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qian, F., Ni, N., Chen, JW. et al. Formation of Zinc–Peptide Spherical Microparticles During Lyophilization from tert-Butyl Alcohol/Water Co-solvent System. Pharm Res 25, 2799–2806 (2008). https://doi.org/10.1007/s11095-008-9647-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-008-9647-7