Abstract

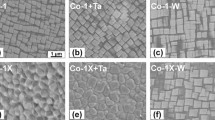

Flake and spheroidal graphite cast irons with similar composition were subjected to high temperature oxidation to investigate graphite morphology and distribution effects on the oxidation behavior. High temperature oxidation tests were conducted between 400 and 750 °C in air. For comparison low carbon steel was also tested.Graphite morphology obviously affected high-temperature oxidation resistance. The flake graphite cast iron exhibited the worst high-temperature oxidation resistance compared with spheroidal graphite cast iron. Since graphite flakes provide suitable sites for the iron oxide growth and are almost interconnected, the iron oxide grows faster and penetrates along the graphite flakes boundaries resulting in the subsurface oxidation. Due to the severe subsurface oxidation flake graphite cast iron parabolic rate constants are five times higher than that of the spheroidal graphite cast iron. However, spheroidal graphite cast iron parabolic rate constants and oxide layer thickness are similar to those of the low carbon steel. Therefore, graphite flakes have negative effect on the cast iron high temperature oxidation resistance.

Similar content being viewed by others

References

C. Labrecque and M. Gagne, Canadian Metallurgical Quarterly 37, 343 (1998).

P. Curcio, B. Kerezsi, and P. Brown, Journal of Materials Science 34, 4775 (1999).

G. S. Cho, K. H. Choe, K. W. Lee, and A. Ikenaga, Journal of Materials Science and Technology 23, 97 (2007).

A. R. Ghaderi, M. Nili Ahmadabadi, and H. M. Ghasemi, Wear 225, 410 (2003).

M. Hatate, T. Shoita, N. Takahashi, and K. Shimizu, Wear 251, 885 (2001).

Y. Zhang, Y. Chen, R. He, and B. Shen, Wear 166, 179 (1993).

T. Ban, Corrosion Science 19, 1979 (289).

F. Tholence, Surface Interface Analysis 34, 535 (2002).

A. Atkinson, Corrosion Science 22, 87 (1982).

J. Robertson and M. I. Manning, Materials Science and Technology 5, 741 (1989).

A. S. Khanna, High Temperature Oxidation and Corrosion (ASM International, 2002), p. 84.

P. Kofstad, Nonstoichiometry, Diffusion and Electrical Conductivity in Binary Metal Oxides, (Wiley-Interscience, New York, 1972).

D. R. Gaskell, Introduction to the Thermodynamics (McGraw-Hill International, New York), p. 585.

D. D. Double and A. Hellawell, Acta Metallurgica 22, 481 (1974).

Acknowledgments

The authors acknowledge support from the National Science Council of Republic of China under grant NSC 98-2221-E-011-038. Alex Volinsky would like to acknowledge support from the National Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, MB., Wang, CJ. & Volinsky, A.A. High Temperature Oxidation Behavior of Flake and Spheroidal Graphite Cast Irons. Oxid Met 76, 161–168 (2011). https://doi.org/10.1007/s11085-011-9244-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-011-9244-8