Abstract

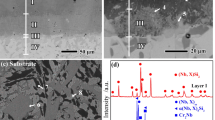

The microstructure and oxidation resistance of NbSi2 coating formed on Nb-based alloy C-103 by a pack siliconization process have been studied. The as-formed coating consists of an outer NbSi2 layer and an inner Nb5Si3 layer. A NbSi2–Nb5Si3 two-phase zone is also present between the above two layers. Weight-change data obtained under isothermal and cyclic oxidation in air at 1100 and 1300°C, suggests that the coating gives oxidation protection up to about 4 h. The oxide scale that formed on the coating during oxidation exposure consists of an outer glassy silica layer and an inner Nb2O5-silica mixed layer. Nb2O5 phase is also present in the outer silica scale in the form of elongated particles. Oxidation protection is achieved primarily by the presence of the glassy silica layer on the surface. Spallation of this layer during thermal cycling causes significant reduction in the protective life of the coating.

Similar content being viewed by others

References

E. A. Loria, Journal of Metals 7, 22 (1987).

R. A. Perkins and G. H. Meier, Journal of Metals 8, 17 (1990).

C. S. Giggins and F. S. Pettit, Journal of the Electrochemical Society 118, 1782 (1971).

T. P. Chow, K. Hamzeh, and A. J. Steckl, Journal of Applied Physics 54(5), 2716 (1983).

R. Bianco, M. A. Harper, and R. A. Rapp, Journal of Mineral Metals and Material Society (JOM) 11, 68 (1991).

Y. Li, W. Soboyejo, and R. A. Rapp, Metallurgical Materials Transactions B 30(3), 495 (1999).

M. R. Jackson, US Patent 4904546, (1990).

M. Levy, J. J. Falco, and R. B. Herring, Journal of Less Common Metals 34, 321 (1974).

M. Vilasi, M. Francois, R. Podor, and J. Steinmetz, Journal of Alloys and Compounds 264, 244 (1998).

M. Jackson, R. Robert, and A. Melinda, US Patent 5721061, (1998).

S. Priceman and L. Sama, Electrochemical Technology 6(9–10), 315 (1968).

R. O. Suzuki, M. Ishikawa, and K. Ono, Journal of Alloys and Compounds 306, 285 (2000).

R. O. Suzuki, M. Ishikawa, and K. Ono, Journal of Alloys and Compounds 336, 280 (2002).

J. A. Shields Jr., Surface Engineering, ASM Handbook, Vol. 5, revised by J. A. Shields (1999), p. 856.

L. L. Seigle, in Surface Engineering: Surface Modification of Materials, eds. R. Kossowsky and S. C. Singhal (Martinus Nijhoff Publishing, Dordrecht, 1984), p. 345.

R. W. Barlett and R. P. Gage, Transactions Metallurgical Society AIME 233, 968 (1965).

J. Guille and L. Matini, Journal of Material Science Letters 7, 952 (1988).

B. V. Cockeram, Surface Coating Technology 76–77, 20 (1995).

S. Majumdar, T. P. Sengupta, G. B. Kale, and I. G. Sharma, Surface Coating Technology 200, 3713 (2006).

J. E. Restall, Journal of Alloys and Compounds 16, 11 (1968).

H. Baker, ASM Handbook, Vol. 3 (ASM International, Ohio, 1992), p. 2.295.

X. Tian and X. Guo, Surface Coating Technology 203, 1161 (2009).

Md. Z. Alam and D. K. Das, Journal of Alloys and Compounds 487, 335 (2009).

C.M. Packer, Proceedings of the Workshop on the Oxidation of High-Temperature Intermetallics, eds. T. Grobstein and J. Doychak (1988), p. 235.

S. Govindarajan, B. Mishra, D. L. Olson, J. J. Moore, and J. Disam, Surface Coating Technology 76–77, 7 (1995).

S. J. Grisaffe and S. R. Levine, US Patent 3931447 (1976).

H. S. Kim, J. K. Yoon, G. H. Kim, J. M. Doh, S. I. Kwun, and K. T. Hong, Intermetallics 16, 360 (2008).

C. Milanese, V. Buscaglia, F. Maglia, and U. A. Tamburini, Acta Materialia 51, 4837 (2003).

D. K. Das, M. Roy, Vakil. Singh, and S. V. Joshi, Material Science and Technologgy 15, 1199 (1999).

J. Maas, G. Bastin, F. V. Loo, and R. Metselaar, Z Metallkunde 75, 140 (1984).

F. M. d’Heurle, P. Gas, and J. Philibert, Diffusion Defect Data, Pt. A, Defect Diffusion Forum 529, 143 (1997).

M. Salamon and H. Mehrer, Diffusion Defect Data. Pt. A, Defect Diffusion Forum 161, 216 (2000).

R. Pichoir, in Materials and Coatings to Resist High Temperature Corrosion, eds. D. R. Holmes and A. Rahmel (Applied Science Publishers, London, 1978), p. 271.

D. K. Das, V. Singh, and S. V. Joshi, Metallurgical Material Transaction A 29A, 2173 (1998).

S. Shankar, and L. L. Seigle, Metallurgical Material Transaction A 9, 1467 (1978).

P. Kofstad, High Temperature Corrosion (Elsevier Applied Science Publishers, London, 1988), p. 315.

Acknowledgments

The authors acknowledge the assistance provided by the XRD, SEM and EPMA groups of DMRL for characterization of the coating. They are thankful to Director, DMRL, for his permission to publish the present work. This research work has been sponsored by the Defence Research and Development Organization (DRDO).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alam, M.Z., Rao, A.S. & Das, D.K. Microstructure and High Temperature Oxidation Performance of Silicide Coating on Nb-Based Alloy C-103. Oxid Met 73, 513–530 (2010). https://doi.org/10.1007/s11085-010-9190-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-010-9190-x