Abstract

The chemistry of imidazolium-catalyzed imidazolium synthesis was studied as part of an effort to develop a plausible prebiotic synthesis of a small catalytic molecule capable of catalyzing its own synthesis. Specifically, we investigated the one-pot 1-ethyl-3-methylimidazolium acetate (EMIM-Ac) catalyzed synthesis of 1,3-dibutyl-4,5-difuryl-imidazolium acetate (DBDFIM-Ac) from furfural, n-butylamine, formaldehyde, and acetic acid at 80 °C. Liu et al. (2012) had previously demonstrated the first reaction of the synthetic process, the EMIM-Ac catalyzed benzoin condensation of furfural that yields furoin. Our early studies established the second reaction of the synthetic process, the multicomponent reaction of furoin, n-butylamine, formaldehyde, and acetic acid that yields the imidazolium salt, DBDFIM-Ac. Studies of the complete two-reaction process that uses furfural for the synthesis of DBDFIM-Ac showed that the highest yield of DBDFIM-Ac was obtained when the mole ratio of n-butylamine, formaldehyde, and acetic acid relative to furfural was respectively (0.5:0.25:0.25:1.0-furfural), or one-half of the stoichiometric ratio (1.0:0.5:0.5:1.0-furfural). A time course study of the process showed transient formation of furoin, the obligatory reaction intermediate. DBDFIM-Ac and the imidazolium side product, 1,3-dibutyl-4,5-trifuryl-imidazolium acetate (DBTFIM-Ac), were stable under the reaction conditions. Imidazolium products (DBDFIM and DBTFIM) and the furoin intermediate were not formed in control reactions (80 °C, 24 h) in which EMIM catalyst was either absent or replaced with an equal volume of acetonitrile or DMF. The imidazolium product, DBDFIM-Ac, was shown to catalyze the synthesis of structurally similar 1,3-dipentyl-4,5-difuryl-imidazolium acetate (DPDFIM-Ac) from furfural, n-pentylamine, formaldehyde, and acetic acid at 80 °C.

Similar content being viewed by others

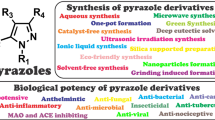

Introduction

One of the generally accepted requirements of the emergence of life is that prebiotically synthesized molecules or molecular systems participating in biogenesis need to feedback and catalyze the chemical processes needed for their persistence and evolution (Pross 2011; Pascal et al. 2013). However, most origins studies have focused on the synthesis of biological monomers and polymers under prebiotic conditions but have not studied or established “catalytic feedback” by the actual products of their synthetic reactions. To develop a prebiotically plausible process that produced molecules capable of catalyzing reactions involved in their own synthesis Clairmont et al. (2015) studied imidazolium-catalyzed imidazolium synthesis. In their model process imidazolium catalysts synthesized from formaldehyde, aniline and acetic acid were shown to catalyze the synthesis of additional imidazolium catalyst. This model process used prebiotically plausible reactants and reactions; however, it was carried out in DMF solvent, and required two temporally separated reactions to produce imidazolium catalysts. Also, the newly synthesized imidazolium catalyst required purification by flash chromatography before it was employed to catalyze the next cycle of imidazolium synthesis.

To better understand and advance the development of a more plausible model of prebiotic imidazolium-catalyzed imidazolium synthesis, we here describe studies of imidazolium-catalyzed imidazolium synthesis that used 1-ethyl-3-methylimidazolium acetate (EMIM-Ac) to catalyze the synthesis of 1,3-dibutyl-4,5-difurylimidazolium acetate (DBDFIM-Ac) from furfural, n-butylamine (nBA), formaldehyde (HCHO), and acetic acid (AcOH). As shown in Scheme 1, initially the synthesis of DBDFIM-Ac was conceived as the three-reaction solvent-free process: 1) EMIM-Ac catalyzed synthesis of furoin from furfural (Liu et al. 2012; Zang et al. 2018; Wilson and Chen 2016), 2) furoin oxidation to furil (Wang et al. 2012; Wilson et al. 2016), and 3) furil reaction with nBA, HCHO, and AcOH to give the desired imidazolium (DBDFIM-Ac) (Zimmermann et al. 2010). Alternatively, previous studies showing imidazole (and possibly imidazolium) synthesis from α-hydroxyketones (dihydroxyacetone and benzoin) suggested that DBDFIM-Ac synthesis might require only two reactions, reaction-1 followed by reaction-4 also shown in Scheme 1 (Clairmont et al. 2015; Siddiqui et al. 2005; Khodaei et al. 2007; Sangshetti et al. 2008; Sivakumar et al. 2010; Mohammadi et al., 2012).

The condensation of furfural to give furoin (reaction-1) is classified as a benzoin condensation (or benzoin addition) in which two aldehydes react to give an acyloin (α-hydroxyaldehyde). There have been numerous studies of catalysis of the benzoin condensation by azolium heterocyclic catalysts, such as imidazolium, thiazolium, and triazolium salts (Enders et al. 2007; Nair et al. 2004). In modern life the thiazolium ring of thiamine is an essential catalytic cofactor for transketolase involved in the reversible benzoin-like transfer of glycolaldehyde from ketoses to the aldehyde of aldoses yielding the terminal α-hydroxyketone group of a new ketose (Kluger and Tittmann 2008). For our studies we selected imidazolium catalysts rather than thiazolium catalysts (e.g. thiamine), because even though thiazolium salts are more effective catalysts, imidazolium salts are more stable (Duclos and Haake 1974) and their prebiotic synthesis is less complicated. The oxidation of furoin to furil (reaction-2) by inorganic oxidants has been examined by Wilson and Chen (2016) and Wang et al. (2012). Reaction-3, the multicomponent reaction of furil, nBA, HCHO, AcOH that yields the desired imidazolium salt product was thoroughly studied by Zimmermann et al. (2010). This reaction is a variant of the Radziszewski reaction for the synthesis of imidazoles from a diketone, an aldehyde, and ammonia (July et al. 2014; Radziszewski 1882). The Radziszewski reaction is also considered a source of imidazoles detected in modern atmospheric ambient aerosol particles (Teich et al. 2016), and imidazolium products synthesized in model studies of simulated evaporating cloud droplets (De Haan et al. 2011).

Experimental

Materials

All reagents were purchased from Sigma-Aldrich and used without additional purification (furfural 99%, furoin 98%, furil 98%, formaldehyde (HCHO 37 wt.% in H2O), n-butylamine (nBA) 99.5%, n-amylamine (n-pentylamine) 99%, acetic acid (AcOH) ≥99%, 1-ethyl-3-methylimidazolium acetate (EMIM-Ac) 97%, HPLC grade acetonitrile (ACN) and methanol, ammonium acetate 99.99 + %, Dimethyl sulfoxide-d6 (DMSO-d6), and 1,3,5-trimethoxybenzene (TraceCERT®).

HPLC Analysis

HPLC analysis was performed on a Shimadzu Prominence LC-2039C HPLC System equipped with a Shimadzu PDA detector (4 nm bandwidth) and autosampler (15 °C). Reaction samples were diluted 1600-fold with 50% aqueous ACN, and 5.0 μl samples injected and separated on a reverse phase Shimadzu C-18 column (3 μm, 4.6 × 50 mm) at 30 °C at a 1 ml/min flow rate using eluent-A (10 mM aqueous ammonium acetate) and eluent-B (ACN). The elution gradient began with 20% B (80% A). After injection the eluent was changed to 80% B over 15 min, and then decreased to 20% B over 3 min, and maintained at 20% B until the end of the run at 28 min. HPLC elution times (min): furfural (1.15), furoin (1.95), furil (3.72), U1 (4.02), U2 (4.15). U3 (5.16), U4 (6.25), U5 (8.04), U6 (8.21), DBDFIM (8.40), DBTFIM (10.35), DPDFIM (10.77), and DPTFIM (12.43).

HPLC analysis at 270 nm of diluted samples of the QNMR-analyzed solution (calc. Conc. 0.113 M) of the purified DBDFIM-Ac preparation provided an estimate of the ratio of HPLC peak area to solution’s molar concentration that was used to calculate (from reaction HPLC peaks areas) the percent yields of DBDFIM from furoin and furfural (see Figs. 2a,b and 4a,b).

TLC Analysis

Thin-layer chromatography used Merck HPTLC Silica gel RP-18 WF254S plates that were eluted with ACN/0.20 M ammonium acetate (55/45 v/v). Reaction solutions were diluted 10-fold with water before being applied to the TLC plate. After development the TLC plates were illuminated by a Spectroline UV-312 nm transilluminator to visualize UV absorbing substances as dark spots. The plates were photographed using a Sony NEZ-5R camera, and NIH’s ImageJ image processing program (http://imagej.nih.gov/ij/) was used to split the RGB photographic images into their red, green, and blue channels. The green channel was used for Fig. 1. Relative TLC mobility: furoin (1.0) DBDFIM (0.32), unknown-1 (0.66), unknown-2 (0.65), furil (0.84). Unknown-1 and unknown-2 are different substances, since they were separated by TLC using ACN/0.20 M ammonium acetate (60/40 v/v).

NMR Analysis

1H, 13C, COSY, HMBC and HSQC NMR data (including QNMR data) were obtained using a Bruker Avance III HD 500 MHz spectrometer equipped with a multinuclear Smart Probe. These experiments were conducted using the NMR Facility located within the Department of Chemistry and Biochemistry at the University of California, Santa Cruz. QNMR was performed using 1,3,5-trimethoxybenzene as an internal standard in DMSO-d6 (“Quantitative NMR Sigma-Aldrich technical document”).

Mass Analysis

Mass spectral data were recorded on a Thermo Finnigan LCQ Deca Max XP (Thermo-Fisher San Jose), equipped with an electrospray ionization source probe assembly with detection in the positive mode polarity. Samples were purified using the preparative TLC procedure (see below) and diluted 1600-fold with 50% aqueous ACN before introduction into the spectrometer using a direct infusion method via the on-board syringe pump at 3 uL/min.

Early Studies of 1,3-Dibutyl-2,4,5-Trifuryl-Imidazolium Acetate (DBTFIM-Ac) Synthesis by Reaction of Furil (or Furoin) with N-Butylamine, Acetic Acid, and Formaldehyde

Reactions were performed using batch method-IV described by Zimmermann et al. (2010). N-Butylamine (2.0 mmole), AcOH (1.0 mmole), and HCHO (1.0 mmole) were added to a 10 ml reaction tube and reacted 30 min at 0 °C. This solution was then added to a solution containing 1.0 mmole furil (or furoin) in 2.5 ml ACN. Next, 400 μl aliquots of the furil and furoin reaction solutions were added to each of five Shimadzu HPLC 1.5 ml glass screw cap vials. Each vial had its screw thread wrapped twice around with Poly-Temp PTFE tape (0.5″ medium density) to prevent escape of volatile contents from the capped vials (soln. wt. loss ≤0.15%). The reaction vials were heated at 80 °C in a Pierce Reacti-Therm aluminum block heater for 0 h, 0.5 h, 1 h, 2 h, 24 h, and stored at −80 °C until analyzed using TLC (Fig. 1).

Time Course of DBTFIM-Ac Synthesis from Furoin, N-Butylamine, Acetic Acid, and Formaldehyde

The reaction solution was prepared by adding nBA (5.0 mmole), AcOH (2.5 mmole), HCHO (2.5 mmole), and a furoin solution (2.5 mmole in 6.25 ml ACN) in the order listed to a glass test tube. Aliquots (400 μl) of this solution were immediately transferred to PTFE wrapped 1.5 ml HPLC vials that (as described earlier) were capped, heated at 80 °C, and stored until analyzed by HPLC.

Time Course of DBDFIM-Ac Synthesis from Furfural, N-Butylamine, Acetic Acid, and Formaldehyde Catalyzed by EMIM-Ac

Reaction solutions were prepared by adding nBA (0.6 mmole), AcOH (0.3 mmole), HCHO (0.3 mmole), and EMIM-Ac (1.2 mmole), furfural (1.2 mmole) in the order listed to PTFE wrapped 1.5 ml HPLC vials that (as described earlier) were capped, heated at 80 °C (0-48 h), and stored until analyzed by HPLC. Imidazolium products (DBDFIM and DBTFIM) and the furoin intermediate were not formed in similar control reactions (80 °C, 24 h) in which EMIM catalyst was either absent or replaced with an equal volume of acetonitrile or DMF.

Effect of Reactant Ratios on DBDFIM-Ac Synthesis from Furfural, N-Butylamine, Acetic Acid, and Formaldehyde Catalyzed by EMIM-Ac

Furfural (1.2 mmole) and EMIM-Ac (1.2 mmole) were reacted with 20%, 40%, 50%, 60%, 80%, and 100% of the stoichiometric amounts of nBA, AcOH, and HCHO. The respective mmoles of nBA were 0.24, 0.48, 0.60, 0.72, 0.96, 1.2, and the respective mmoles of AcOH and HCHO were 0.12, 0.24, 0.30, 0.36, 0.48, 0.60. Reaction solutions were prepared by adding the above amounts of nBA, AcOH, HCHO, EMIM-Ac, and furfural in the order listed to PTFE wrapped 1.5 ml HPLC vials that (as described earlier) were capped, heated at 80 °C, and stored until analyzed by HPLC.

TLC Purification of Imidazolium Products for Mass Analysis

DBDFIM-Ac was synthesized from furoin, nBA, AcOH, and HCHO at 60 °C (24 h) using the method described previously under early studies of DBTF-Im synthesis from furoin. A sample of the product was diluted tenfold and streaked across a Merck HPTLC RP-18 W plate. The plate was then developed using methanol/0.2 M ammonium acetate in water (55/45 v/v), and dried 15 min in the hood air flow. The plate was developed a second time using water, dried 15 min in the hood air flow, and then developed a third time using acetone (DBDFIM Rf = 0.23). The area of the plate containing the UV absorbing imidazolium product was scraped off the plate, placed in a Centrex microfiltration tube, eluted twice using 500 μl of methanol / 0.2 M ammonium acetate (85/15 v/v), and dried twice in vacuo in a CentriVap centrifugal evaporator at 40 °C after adding back methanol. The identity of imidazolium product was confirmed by electrospray mass spectrometry (DBDFIM expected m/z = 313.19, found m/z = 313.32).

DBDFIM-Ac and DBTFIM-Ac were also synthesized from furfural, nBA, AcOH, HCHO, and EMIM catalyst at 80 °C (24 h) using the method described under the time course of DBDFIM-Ac synthesis from furfural. The identities of the imidazolium cations that had been isolated by TLC were confirmed by electrospray mass spectrometry: DBDFIM (expected m/z = 313.19, found m/z = 313.38); DBTFIM (expected m/z = 379.20, found m/z = 379.36). The TLC purification method was the same as described earlier, except that the TLC plate was developed using ACN/0.2 M ammonium acetate (6/5 v/v) DBDFIM Rf = 0.22; DBTFIM Rf = 0.16).

In addition we examined the ability of DBDFIM-Ac and EMIM-Ac to catalyze the synthesis of 1,3-dipentyl-4,5-difuryl-imidazolium acetate (DPDFIM-Ac) and 1,3-dipentyl-4,5-trifuryl-imidazolium acetate (DPTFIM-Ac) from furfural, n-pentylamine, AcOH, and HCHO at 80 °C (24 h) using the method described under the time course of DBDFIM-Ac synthesis from furfural. The identities of the DPDFIM and DPTFIM cations isolated by TLC were confirmed by electrospray mass spectrometry: DPDFIM (expected m/z = 341.22, found = 341.28); DPTFIM (expected m/z = 407.23, found m/z = 407.23). TLC purification method was the same as described earlier, except that the TLC plate was developed using ACN/0.2 M ammonium acetate (3/2 v/v) DPDFIM Rf = 0.2; DPTFIM Rf = 0.07).

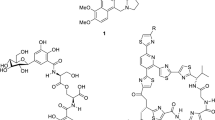

Preparation and Column Purification of DBDFIM-Ac

N-Butylamine (5.0 mmol), AcOH (3.0 mmol), and 37% aqueous HCHO (2.5 mmol) were added as listed to a 5 ml reaction vial and reacted at 0 °C for 30 min. This solution was added to a solution of furoin (2.5 mmol in 6.25 ml ACN) and reacted at 80 °C for 4 h. The reaction product was concentrated to 1 ml volume in vacuo in a CentriVap centrifugal evaporator. Saturated sodium bicarbonate (150 μl) was added and a 0.4 ml aliquot was applied to a Supelco Discovery-DSC-18 column (5 g in 20 ml tube). The column was pre-conditioned with MeOH and eluted with 18 ml water, 18 ml acetone, 18 ml MeOH, and 18 ml 0.1 M ammonium acetate in MeOH. The first 6 ml of the 0.1 M ammonium acetate/MeOH solution was collected and dried extensively in vacuo in a rotary evaporator. The structure of DBDFIM-Ac was confirmed using 1D and 2D proton/ carbon nuclear magnetic resonance spectroscopy and electrospray mass spectrometry. 1H NMR (500 MHz, DMSO-d6) δ 10.10 (s, 1H), 8.02–7.98 (m, 2H), 6.93 (d, J = 3.5 Hz, 2H), 6.73 (dd, J = 3.5, 1.8 Hz, 2H), 4.26 (t, J = 7.3 Hz, 4H), 1.72–1.63 (m, H), 1.28 (h, J = 7.4 Hz, 4H), 0.86 (t, J = 7.4 Hz, 6H); 13C NMR (126 MHz, DMSO-d6) δ 173.88, 146.56, 139.40, 138.31, 123.50, 123.48, 115.53, 112.48, 48.99, 31.23, 24.86, 19.22, 13.66; ESI-MS (+): Calculated MW for DBDFIM = 313.41, found m/z = 313.38. QNMR analysis using 1,3,5-trimethoxybenzene as an internal standard showed the purified preparation contained 89–93% DBDFIM-Ac.

Results

DBDFIM-Ac Synthesis from Furil and Furoin

To develop an understanding of the chemistry of the imidazolium synthesis pathway described in Scheme 1, we initially examined the synthesis of DBDFIM-Ac by reacting furil and furoin with nBA, AcOH, and HCHO in acetonitrile. Our method was based on batch method (IV) used by Zimmermann et al. (2010) that yielded imidazolium salts from an aqueous solution of glyoxal (an α-ketoaldehyde), nBA, HCHO, and acetic acid. As shown in Fig. 1, we discovered that furoin (an α-hydroxyketone) gave a much higher yield of DBDFIM-Ac than furil. This reaction also gave high yields of DBDFIM-Ac when carried out for 9 days at 25 °C. The identity of DBDFIM-Ac was confirmed by electrospray mass spectrometry and 1H NMR. The nature of the dehydrogenation process needed to produce DBDFIM-Ac from the α-hydroxyketone (furoin) is unknown. However, as described earlier there have been several reports of imidazole synthesis from α-hydroxyketones.

Since the above results supported the direct synthesis of DBDFIM-Ac from furoin, nBA, HCHO, and acetic acid, we next measured the time course of DBDFIM production from furoin, nBA, HCHO, and AcOH in acetonitrile at 80 °C. Figure 2a shows the HPLC profile of furoin and derived reaction products at 0.5 h monitored at 270 nm. Figure 2b shows the time course of product formation from furoin, nBA, HCHO, and AcOH in acetonitrile. In the first 0.5 h of reaction there is a rapid decrease in furoin concentration that is accompanied by formation of (a) DBDFIM and (b) unidentified transient products U1 and U2. A small amount of furil also forms before the first measurement at 0.5 h and then decreases. Furil, U1, and U2 could be reaction intermediates in DBDFIM synthesis, because their formation and disappearance coincide with the production of DBDFIM. However, our earlier observation that DBDFIM-Ac synthesis is slow and inefficient with furil compared to furoin suggests that furil is not an intermediate in DBDFIM synthesis. The synthesis of DBDFIM and unidentified products U4 and U5 is complete at about 3 h. DBDFIM-Ac appears to be stable under the reaction conditions. At 7 h the DBDFIM yield was 62.5% (based on formaldehyde) estimated using QNMR and HPLC. When the reaction was performed under anaerobic conditions in 1 ml glass Wheaton vacuoles, the imidazolium salt yield was 90% that of the reaction in the capped 1.5 ml Shimadzu vials containing air. TLC analysis showed that furoin alone dissolved in ACN was stable when heated at 80 °C for 4 h under aerobic and anaerobic conditions (± 15 mM acetic acid).

The discovery that DBDFIM-Ac could be synthesized directly from furoin (an α-hydroxyaldehyde) led us to propose the simpler pathway shown in Scheme 2 for the synthesis of DBDFIM from furfural, nBA, HCHO, and AcOH. In this revised pathway EMIM catalyzes the benzoin condensation of furfural to give the furoin intermediate (Liu et al. 2012) that then reacts with nBA, HCHO, AcOH to produce DBDFIM. To determine if these two reactions could occur concurrently, we examined the overall functioning of the complete pathway, which is the one-pot EMIM catalyzed synthesis of DBDFIM-Ac from furfural, nBA, HCHO, AcOH. No solvent was used in our studies of imidazolium synthesis from furfural because all the reactants were liquid, and Liu’s synthesis of furoin from furfural was solvent-free (Liu et al. 2012).

DBDFIM-Ac Synthesis from Furfural

In our first study of imidazolium synthesis from furfural we reacted stoichiometric and lower amounts of nBA, HCHO, AcOH with a fixed quantity (1.2 mmol) of furfural and EMIM-Ac. As shown in Fig. 3 the reaction yielded two imidazoliums: the desired product, DBDFIM-Ac, and the side product, 1,3-dibutyl-2,4,5-trifuryl-imidazolium acetate (DBTFIM-Ac), depicted in Scheme 2. The identities of DBDFIM (m/z-313) and DBTFIM (m/z-379) were confirmed by electrospray mass spectrometry. During imidazolium synthesis, formaldehyde becomes the C2-carbon of DBDFIM; whereas, furfural’s aldehyde becomes the C2-carbon of DBTFIM. In Fig. 3 the stoichiometric reaction is marked with an asterisk. Unexpectedly, the stoichiometric reaction did not produce the highest yield of DBDFIM-Ac. Instead the best yield of DBDFIM-Ac was observed when 50% of the stoichiometric amounts of nBA, AcOH, HCHO were reacted with furfural (mmoles respectively = 0.6, 0.3, 0.3, 1.2-furfural). Above 50% of the stoichiometric amounts of nBA, AcOH, and HCHO there is a sharp decrease in the yields of the furoin intermediate and imidazolium products (DBDFIM-Ac, DBTFIM-Ac) and a coincident increase in unreacted furfural. These observations suggest that when the amount of nBA, AcOH, and HCHO exceeds 50% of their stoichiometric amount, one or more of these reactants interferes with EMIM-catalyzed synthesis of furoin required for imidazolium synthesis.

The effect on imidazolium synthesis of reacting less than stoichiometric amounts of n-BA, AcOH, and HCHO with the furfural and EMIM-Ac held constant at 1.2 mmol. The stoichiometric reaction marked with an asterisk in Fig. 3 contained: nBA (1.2 mmol), AcOH (0.6 mmol), HCHO (0.6 mmol), and furfural (1.2 mmol)

To explore the chemistry of imidazolium synthesis from furfural we next examined the time course of DBDFIM synthesis. This reaction used the optimal ratio of reactants determined in the Fig. 3 study. Figure 4a shows the HPLC separation of furfural and derived reaction products at 10 h monitored at 270 nm. Figure 4b shows the time course of the synthesis of DBDFIM and other products from the EMIM-Ac catalyzed reaction of furfural, nBA, HCHO, and AcOH at 80 °C. In the first 5 h of reaction there is a rapid decrease of furfural concentration that is accompanied by formation of (a) furoin, and (b) furil and unidentified products U1 and U2. Since furil, U1, and U2 were shown earlier to be transient products in the synthesis of DBDFIM from furoin (see Fig. 2b) these are furoin-derived products that could be involved in DBDFIM synthesis. Unidentified product U3 which is found in the zero-time reaction but not the furfural reagent also undergoes rapid decrease in the first 5 h of reaction. U3’s rapid formation (possibly during sample preparation at 25 °C) suggests it might be the addition product of furfural with the C2-carbon of EMIM. DBDFIM, DBTFIM, and U5 appear to be stable products of the reaction that ends in 30 h. At 48 h the DBDFIM yield was 33.0% (based on formaldehyde) estimated using QNMR and HPLC. Imidazolium products (DBDFIM and DBTFIM) and the furoin intermediate were not formed in similar control reactions (80 °C, 24 h) in which EMIM catalyst was either absent or replaced with an equal volume of acetonitrile or DMF.

Catalytic Activity of the DBDFIM-Ac Imidazolium Product

To establish the catalytic activity of the DBDFIM-Ac product, purified DBDFIM-Ac and commercial EMIM-Ac were each tested as catalysts for the synthesis of the structurally related 1,3-dipentyl-4,5-difuryl-imidazolium acetate (DPDFIM-Ac) and its side product 1,3-dipentyl-4,5-trifuryl-imidazolium acetate (DPTFIM-Ac) from furfural, n-pentylamine, formaldehyde, and acetic acid at 80 °C (24 h). HPLC analysis showed that DBDFIM-Ac and EMIM-Ac both catalyzed the synthesis DPDFIM-Ac and DPTFIM-Ac. The DPDFIM-Ac yield using DBDFIM-Ac was about 70% its yield using EMIM-Ac.

Discussion

Chemistry

Our studies demonstrate that an imidazolium salt (EMIM-Ac) can catalyze the solvent-free, one-pot synthesis of another catalytic imidazolium salt, (DBDFIM-Ac). As shown in Fig. 4b this synthetic process is a concurrent two-reaction process: (1) EMIM-Ac catalyzed furoin synthesis followed by (2) furoin reaction with nBA, HCHO, and AcOH to give DBDFIM-Ac. The synthetic capability of this process derives from (1) the surprising ability of simple imidazolium salt of a weak base (EMIM-Ac) to catalyze the benzoin condensation of furfural to furoin in the presence of a considerable amount of protic molecules that would be expected to quench formation of the imidazolium carbene intermediate needed for catalysis (Clairmont et al. 2015), (2) the anaerobic synthesis of DBDFIM-Ac from furoin (an α-hydroxyketone) reacted with nBA, HCHO and AcOH, (3) the ability of the EMIM-Ac to act as both catalyst and solvent, and (4) the stability of imidazolium products under the reaction conditions. The chemistry of this model of imidazolium-catalyzed imidazolium synthesis is simpler than the model reported earlier by Clairmont et al. (2015) because here imidazolium synthesis from furfural proceeds via furoin, rather than formaldehyde derived sugars which can undergo isomerization, dehydration, aldol-retro-aldol reactions, and Maillard degradation reactions under the reaction conditions. However, Clairmont’s model used formaldehyde which is a more prebiotically plausible reactant than furfural. Presumably under prebiotic conditions furfural could have formed by dehydration of ketopentoses (Choudhary et al. 2011) derived from formaldehyde.

The formation of imidazolium catalysts from the reaction of amines with sugars (Clairmont et al. 2015) or sugar-derived furfural (this study) suggests that related Maillard sugar-amino acid reactions could generate imidazolium salts capable of catalyzing Maillard transformations (aldehyde benzoin condensations and oxidations), thereby influencing the chemical dynamics of the Maillard process.

The development of an imidazolium model capable of sustained autocatalytic growth in the presence of water probably requires the synthesis of an amphiphilic imidazolium (Lin et al. 2011; Jungnickel et al. 2008) that could catalyze self-synthesis while bound to a hydrophobic resin in a column. Periodic elution of the column with fresh reactants should enable continued synthesis and accumulation of imidazolium catalyst and removal of waste products (Wang and Chen 2015; Yan et al. 2016). Related benzimidazolium salts possessing N-(C12-alkyl)-substituents have been shown to catalyze the benzoin condensation in the presence of water (Iwamoto et al. 2006).

Prebiotic relevance

In addition to their ability to catalyze self-synthesis from an aldehyde, an amine, formaldehyde, and acetic acid, imidazolium salts have other structural and functional properties that make them attractive prebiotic molecules. First, the Radziszewski reaction is capable of producing a variety of imidazolium salts possessing different N1,N3,C4,C5-ring substituents. This structural complexity comes from (1) the large number of amines that can be used for the synthesis of the N1,N3-substituents of the imidazolium ring (e.g. amino acids, peptides, aniline, alkylamines) (Davidek et al. 1991; Velisek et al. 1992; Clairmont et al. 2015; Zimmermann et al. 2010), and (2) the many carbon substrates (1,2-dicarbonyls (e. g. glyoxal) and α-hydroxyketones (e.g. sugars, furoin) that can be used for the synthesis of the C4,C5-substituents of the imidazolium ring (Zimmermann et al. 2010; Clairmont et al. 2015; Siddiqui et al. 2005). The Radziszewski reaction is also capable of producing large imidazolium polymers from glyoxal, formaldehyde, and a diamine (e.g. lysine) (Lindner 2016; Saxer et al. 2018). Moreover, azolium (thiazolium and imidazolium) catalysis is not limited to the benzoin condensation (Enders 2007). For example, azolium salts have been shown to catalyze oxidation reactions that model biological pyruvate oxidative decarboxylation, the energy-transducing process that yields acetyl-CoA from pyruvate, and connects glycolysis to the citric acid cycle (Knappke et al. 2012; Kageyama and Murata 2005; Guin et al. 2008; Kiran et al. 2013).

References

Choudhary V, Pinar AB, Sandler SI, Vlachos DG, Lobo RF (2011) Xylose isomerization to xylulose and its dehydration to furfural in aqueous media. ACS Catal 1:1724–1728. https://doi.org/10.1021/cs200461t

Clairmont RM, Bommarius AS, Weber AL (2015) Imidazolium catalysts formed by an iterative synthetic process as a model system for chemical evolution. J Mol Evol 81:1–9. https://doi.org/10.1007/s00239-015-9687-7

Davidek T, Velisek J, Davidek J, Pech P (1991) Glycylglycine-derived 1,3-disubstituted imidazole in nonenzymic browning reactions. J Agric Food Chem 39:1374–1377. https://doi.org/10.1021/jf00008a004

De Haan DO, Hawkins LN, Kononenko JA, Turley JJ, Corrigan AL, Tolbert MA, Jimenez JA (2011) Formation of nitrogen-containing oligomers by methylglyoxal and amines in simulated evaporating cloud droplets. Environ Sci Technol 45:984–991. https://doi.org/10.1021/es102933x

Duclos JM, Haake P (1974) Ring opening of thiamine analogs. The role of ring opening in physiological function Biochem 13:5358–5362. https://doi.org/10.1021/bi00723a016

Enders D, Niemeier O, Henseler A (2007) Organocatalysis by N-heterocyclic carbenes. Chem Rev 107:5606–5655. https://doi.org/10.1021/cr068372z

Guin J, De Sarkar S, Grimme S, Studer A (2008) Biomimetic carbene-catalyzed oxidations of aldehydes using TEMPO. Angew Chem Int Ed Engl 47:8727–8730. https://doi.org/10.1002/anie.200802735

Iwamoto K, Hamaya M, Hashimoto N, Kimura H, Suzuki Y, Sato M (2006) Benzoin reaction in water as an aqueous medium catalyzed by benzimidazolium salt. Chem Inform 38:7175–7177. https://doi.org/10.1002/chin.200702079

July A, Munoz H, Joel J, Flavia MS (2014) Radziszewski reaction: an elegant, easy, simple and efficient method to synthesise imidazoles. Cur Org Synth 11:824–834. https://doi.org/10.2174/1570179411666140623223611

Jungnickel C, Łuczak J, Ranke J, Fernández JF, Müller A, Thöming J (2008) Micelle formation of imidazolium ionic liquids in aqueous solution. Colloids and Surf A 316:278–284. https://doi.org/10.1016/j.colsurfa.2007.09.020

Kageyama Y, Murata S (2005) Oxidative formation of thiolesters in a model system of the pyruvate dehydrogenase complex. J Org Chem 70:3140–3147. https://doi.org/10.1021/jo047737h

Khodaei MM, Bahrami K, Kavianinia I (2007) P-TSA catalyzed synthesis of 2,4,5-triarylimidazoles from ammonium heptamolybdate tetrahydrate in TBAI. J Chin Chem Soc 54:829–833. https://doi.org/10.1002/jccs.200700121

Kiran INC, Lalwani K, Sudalai A (2013) N-heterocyclic carbene catalyzed esterification of aromatic aldehydes with alcohols under aerobic conditions. RSC Adv 3:1695–1698. https://doi.org/10.1039/C2RA22718E

Kluger R, Tittmann K (2008) Thiamin diphosphate catalysis: enzymic and nonenzymic covalent intermediates. Chem Rev 108:1797–1833. https://doi.org/10.1021/cr068444m

Knappke CEI, Imami A, Wangelin AJ (2012) Oxidative N-heterocyclic carbene catalysis. Chem Cat Chem 4:937–941. https://doi.org/10.1002/cctc.201200133

Lin JC, Huang CJ, Lee YT, Lee KM, Lin IJ (2011) Carboxylic acid functionalized imidazolium salts: sequential formation of ionic, zwitterionic, acid-zwitterionic and lithium salt-zwitterionic liquid crystals. J Mater Chem 21:8110–8121. https://doi.org/10.1039/C1JM10580A

Lindner J-P (2016) Imidazolium-based polymers via the poly-Radziszewski-reaction. Macromolecules 49:2046–2053. https://doi.org/10.1021/acs.macromol.5b02417

Liu DJ, Zhang Y, Chen EYX (2012) Organocatalytic upgrading of the key biorefining building block by a catalytic ionic liquid and N-heterocyclic carbenes. Green Chem 14:2738–2746. https://doi.org/10.1039/C2GC36265A

Mohammadi A, Keshvari H, Sandaroos R, Rouhi H, Sepehr Z (2012) A novel polymeric catalyst for the one-pot synthesis of 2,4,5-triaryl-1H-imidazoles. J Chem Sci 124:717–722. https://doi.org/10.1007/s12039-012-0248-y

Nair V, Bindu S, Sreekumar V (2004) N-heterocyclic carbenes: reagents, not just ligands. Angew Chem Int Ed Engl 43:5130–5135. https://doi.org/10.1002/anie.200301714

Pascal R, Pross A, Sutherland JD (2013) Towards an evolutionary theory of the origin of life based on kinetics and thermodynamics. Open Biol 3:130156. https://doi.org/10.1098/rsob.130156

Pross A (2011) Toward a general theory of evolution: extending Darwinian theory to inanimate matter. J Syst Chem 2:1–14. https://doi.org/10.1186/1759-2208-2-1

“Quantitative NMR Sigma-Aldrich technical document”. https://www.sigmaaldrich.com/content/dam/sigma-aldrich/docs/Sigma-Aldrich/Brochure/1/qnmr-brochure-rjo.pdf

Radziszewski B (1882) Ueber glyoxalin und seine homologe. Ber Dtsch Chem Ges 15:2706. https://doi.org/10.1002/cber.188201502245

Sangshetti JN, Kokare ND, Kotharkar SA, Shinde DB (2008) Sodium bisulfite as an efficient and inexpensive catalyst for the one-pot synthesis of 2,4,5-triaryl-1H-imidazoles from benzil or benzoin and aromatic aldehydes. Monatsh Chem 139:125–127. https://doi.org/10.1007/s00706-007-0766-3

Saxer S, Marestin C, Mercier R, Dupuy J (2018) The multicomponent debus–Radziszewski reaction in macromolecular chemistry. Polym Chem:1927–1933. https://doi.org/10.1039/C8PY00173A

Siddiqui SA, Narkhede UC, Palimkar SS, Daniel T, Lahoti RJ, Srinivasan KV (2005) Room temperature ionic liquid promoted improved and rapid synthesis of 2,4,5-triaryl imidazoles from aryl aldehydes and 1,2-diketones or α-hydroxyketone. ChemInform 36:3539–3546. https://doi.org/10.1002/chin.200531131

Sivakumar K, Kathirvel A, Lalitha A (2010) Simple and efficient method for the synthesis of highly substituted imidazoles using zeolite-supported reagents. Tetrahedron Lett 51:3018–3021. https://doi.org/10.1016/j.tetlet.2010.04.013

Teich M, Pinxteren D, Kecorius S, Wang Z, Herrmann H (2016) First quantification of imidazoles in ambient aerosol particles: potential photosensitizers, brown carbon constituents, and hazardous components. Environ Sci Technol 50:1166–1173. https://doi.org/10.1021/acs.est.5b05474

Velisek J, Davidek T, Davidek J (1992) 1,3-Disubstituted imidazoles in the glucose-glycine Maillard reaction. Lebensm-Wissen Technol 25:74–76

Wang L, Chen EYX (2015) Recyclable supported carbene catalysts for high-yielding self-condensation of furaldehydes into C10 and C12 furoins. ACS Catal 5:6907–6917. https://doi.org/10.1021/acscatal.5b01410

Wang LY, Meng D, Li L, Cai X (2012) An efficient synthesis of furil. Adv Mater Res 554-556:764–767. https://doi.org/10.4028/www.scientific.net/AMR.554-556.764

Wilson J, Chen EYX (2016) Organocatalytic cross-coupling of biofuranics to multifunctional difuranic C11 building blocks. ACS Sustain Chem Eng 4:4927–4936. https://doi.org/10.1021/acssuschemeng.6b01235

Yan B, Zang H, Jiang Y, Yu S, Chen EYX (2016) Recyclable montmorillonite-supported thiazolium ionic liquids for high-yielding and solvent-free upgrading of furfural and 5-hydroxymethylfurfural to C10 and C12 furoins. RSC Adv 6:76707–76715. https://doi.org/10.1039/C6RA14594A

Zang H, Wang K, Zhang M, Xie R, Wang L, Chen EYX (2018) Catalytic coupling of biomass-derived aldehydes into intermediates for biofuels and materials. Catal Sci Technol 8:1777–1798. https://doi.org/10.1039/C7CY02221B

Zimmermann J, Ondruschka B, Stark A (2010) Efficient synthesis of 1,3-dialkylimidazolium-based ionic liquids: the modified continuous Radziszewski reaction in a microreactor setup. Org Process Res Dev 14:1102–1109. https://doi.org/10.1021/op100055f

Acknowledgements

The authors thank Esther Varon for technical assistance in this study. This investigation was supported by a grant (NNX15AL19G) from the Exobiology Program of the National Aeronautics and Space Administration. ACR was supported by Exobiology Program grant, NNH17ZDA001N-EXO.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Weber, A.L., Rios, A.C. Imidazolium-Catalyzed Synthesis of an Imidazolium Catalyst. Orig Life Evol Biosph 49, 199–211 (2019). https://doi.org/10.1007/s11084-019-09589-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11084-019-09589-2