Abstract

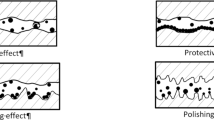

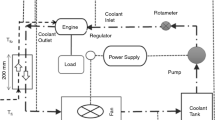

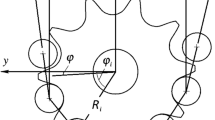

Minimizing of the boundary friction coefficient is critical for engine efficiency improvement. It is known that the tribological behavior has a major role in controlling the performance of automotive engines in terms of the fuel consumption. The purpose of this research is an experimental study to minimize the boundary friction coefficient via nano-lubricant additives. The tribological characteristics of Al2O3 and TiO2 nano-lubricants were evaluated under reciprocating test conditions to simulate a piston ring/cylinder liner interface in automotive engines. The nanoparticles were suspended in a commercially available lubricant in a concentration of 0.25 wt.% to formulate the nano-lubricants. The Al2O3 and TiO2 nanoparticles had sizes of 8–12 and 10 nm, respectively. The experimental results have shown that the boundary friction coefficient reduced by 35–51% near the top and bottom dead center of the stroke (TDC and BDC) for the Al2O3 and TiO2 nano-lubricants, respectively. The anti-wear mechanism was generated via the formation of protective films on the worn surfaces of the ring and liner. These results will be a promising approach for improving fuel economy in automotive.

Minimizing of the boundary friction coefficient in automotive engines using Al2O3 and TiO2 nanoparticles

Similar content being viewed by others

References

Ali MKA, Xianjun H (2015) Improving the tribological behavior of internal combustion engines via the addition of nanoparticles to engine oils. Nanotechnol Rev 4:347–358

Ali MKA, Xianjun H, Mai L, Bicheng C, Turkson RF, Qingping C (2016a) Reducing frictional power losses and improving the scuffing resistance in automotive engines using hybrid nanomaterials as nano-lubricant additives. Wear 364:270–281

Ali MKA, Xianjun H, Mai L, Qingping C, Turkson RF, Bicheng C (2016b) Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribol Int 103:540–554

Ali MKA, Xianjun H, Turkson RF, Ezzat M (2015) An analytical study of tribological parameters between piston ring and cylinder liner in internal combustion engines. P I Mech Eng K-J Mul. doi:10.1177/1464419315605922

Ali MKA, Xianjun H, Turkson RF, Peng Z, Chen X (2016c) Enhancing the thermophysical properties and tribological behaviour of engine oils using nano-lubricant additives. RSC Adv 6:77913–77924

Alves S, Mello V, Faria E, Camargo A (2016) Nanolubricants developed from tiny CuO nanoparticles. Tribolo Int 100:263–271

Bakunin V, Suslov AY, Kuzmina G, Parenago O, Topchiev A (2004) Synthesis and application of inorganic nanoparticles as lubricant components—a review. J Nanopart Res 6:273–284

Battez AH, González R, Viesca J, Fernández J, Fernández JD, Machado A, Riba J (2008) CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 265:422–428

Boshui C, Kecheng G, Jianhua F, Jiang W, Jiu W, Nan Z (2015) Tribological characteristics of monodispersed cerium borate nanospheres in biodegradable rapeseed oil lubricant. Appl Surf Sci 353:326–332

Ghaednia H, Babaei H, Jackson RL, Bozack MJ, Khodadadi J (2013) The effect of nanoparticles on thin film elasto-hydrodynamic lubrication. Appl Phys Lett 103:263111

Gulzar M, Masjuki H, Kalam M, Varman M, Zulkifli N, Mufti R, Zahid R (2016) Tribological performance of nanoparticles as lubricating oil additives. J Nanopart Res 18:1–25

Hsu SM, Gates R (2005) Boundary lubricating films: formation and lubrication mechanism. Tribol Int 38:305–312

Ingole S, Charanpahari A, Kakade A, Umare S, Bhatt D, Menghani J (2013) Tribological behavior of nano TiO2 as an additive in base oil. Wear 301:776–785

Joly-Pottuz L, Vacher B, Le Mogne T, Martin J, Mieno T, He C, Zhao N (2008) The role of nickel in Ni-containing nanotubes and onions as lubricant additives. Tribol Lett 29:213–219

Kao MJ, Lin CR (2009) Evaluating the role of spherical titanium oxide nanoparticles in reducing friction between two pieces of cast iron. J Alloy Compd 483:456–459

Lawrence KD, Ramamoorthy B (2016) Multi-surface topography targeted plateau honing for the processing of cylinder liner surfaces of automotive engines. Appl Surf Sci 365:19–30

Li W, Zheng S, Cao B, Ma S (2011) Friction and wear properties of ZrO2/SiO2 composite nanoparticles. J Nanopart Res 13:2129–2137

Li X, Cao Z, Zhang Z, Dang H (2006) Surface-modification in situ of nano-SiO2 and its structure and tribological properties. Appl Surf Sci 252:7856–7861

Liu G, Li X, Qin B, Xing D, Guo Y, Fan R (2004) Investigation of the mending effect and mechanism of copper nano-particles on a tribologically stressed surface. Tribol Lett 17:961–966

Luo T, Wei X, Zhao H, Cai G, Zheng X (2014) Tribology properties of Al2O3/TiO2 nanocomposites as lubricant additives. Ceram Int 40:10103–10109

Peña-Parás L, Taha-Tijerina J, Garza L, Maldonado-Cortés D, Michalczewski R, Lapray C (2015) Effect of CuO and Al2O3 nanoparticle additives on the tribological behavior of fully formulated oils. Wear 332:1256–1261

Priest M (2000) Factors influencing boundary friction and wear of piston rings. Tribology series 38:409–416

Priest M, Taylor C (2000) Automobile engine tribology—approaching the surface. Wear 241:193–203

Rapoport L, Leshchinsky V, Lapsker I, Volovik Y, Nepomnyashchy O, Lvovsky M, Tenne R (2003) Tribological properties of WS2 nanoparticles under mixed lubrication. Wear 255:785–793

Shahmohamadi H, Mohammadpour M, Rahmani R, Rahnejat H, Garner CP, Howell-Smith S (2015) On the boundary conditions in multi-phase flow through the piston ring-cylinder liner conjunction. Tribol Int 90:164–174

Styles G, Rahmani R, Rahnejat H, Fitzsimons B (2014) In-cycle and life-time friction transience in piston ring–liner conjunction under mixed regime of lubrication. Int J Engine Res 15:862–876

Thamaphat K, Limsuwan P, Ngotawornchai B (2008) Phase characterization of TiO2 powder by XRD and TEM. Kasetsart J(Nat Sci) 42:357–361

Truhan JJ, Qu J, Blau PJ (2005) The effect of lubricating oil condition on the friction and wear of piston ring and cylinder liner materials in a reciprocating bench test. Wear 259:1048–1055

Wan Q, Jin Y, Sun P, Ding Y (2014) Rheological and tribological behaviour of lubricating oils containing platelet MoS2 nanoparticles. J Nanopart Res 16:1–9

Wong VW, Tung SC (2016) Overview of automotive engine friction and reduction trends—effects of surface, material, and lubricant-additive technologies. Friction 4:1–28

Wu Y, Tsui W, Liu T (2007) Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 262:819–825

Xiaohong L, Zhi C, Zhijun Z, Hongxin D (2006) Surface-modification in situ of nano-SiO2 and its structure and tribological properties. Appl Surf Sci 252:7856–7861

Zulkifli N, Kalam M, Masjuki H, Yunus R (2013) Experimental analysis of tribological properties of biolubricant with nanoparticle additive. Procedia Eng 68:152–157. doi:10.1016/j.proeng.2013.12.161

Acknowledgments

The authors would like to express their deep appreciation to the Hubei Key Laboratory of Advanced Technology for Automotive Components (Wuhan University of Technology) for the continuous support. M.K.A. Ali acknowledges the Chinese Scholarship Council (CSC) for the financial support for their PhD studies in the form of CSC grant numbers 2014GF032. M.K.A. Ali also appreciates the financial support from the Egyptian Government. We also wish to thank the various anonymous reviewers for their helpful and valuable comments.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Ali, M.K.A., Xianjun, H., Elagouz, A. et al. Minimizing of the boundary friction coefficient in automotive engines using Al2O3 and TiO2 nanoparticles. J Nanopart Res 18, 377 (2016). https://doi.org/10.1007/s11051-016-3679-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-016-3679-4