Abstract

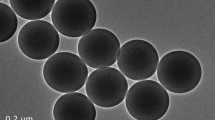

The core/shell-structured organic/inorganic composite abrasive has an important potential application in damage-free chemical mechanical polishing (CMP) due to its non-rigid mechanical property. In this work, the PS/ M SiO2 composites, containing polystyrene (PS) sphere (211 ± 4 nm) cores and mesoporous silica shells (31 ± 3 nm in thickness) were synthesized through directed surface sol–gel process of tetraethylorthosilicate on the polymer cores in the presence of the cetyltrimethylammonium bromide surfactant. For comparison, the conventional core/shell PS/ N SiO2 composites with non-porous silica shells were also prepared via a modified Stöber procedure that involved the hydrolysis of TEOS under acidic condition. The physical properties of the samples were examined by small-angle X-ray diffraction, fourier transform infrared spectroscopy, thermogravimetric analysis, transmission electron microscopy, field emission scanning electron microscopy, and nitrogen adsorption–desorption. As novel abrasives, the core/shell-structured PS/ M SiO2 composites were introduced into the CMP process for silicon oxide films. The oxide-CMP performance among conventional solid silica particles, PS/ N SiO2 composites, and novel PS/ M SiO2 composites was explored by atomic force microscopy. Polishing results indicated that the substrate revealed a comparable root-mean-square surface roughness (0.25 ± 0.03 and 0.22 ± 0.02 nm, respectively) after CMP with PS/ N SiO2 and PS/ M SiO2 abrasives under the same polishing conditions. However, the material removal rate of the PS/ M SiO2 composites (123 ± 15 nm/min) was about three times larger than that of the PS/ N SiO2 composites (47 ± 13 nm/min). The reduced surface roughness and improved removal rate might be due to the optimization of the physical and/or chemical environments in the local contacting region between abrasives and substrates. The as-synthesized core/shell PS/ M SiO2 composites with mesoporous shells are expected to exhibit an important potential application in efficient and damage-free CMP.

Similar content being viewed by others

References

Alyoshina NA, Agafonov AV, Parfenyuk EV (2014) Comparative study of adsorption capacity of mesoporous silica materials for molsidomine: effects of functionalizing and solution pH. Mat Sci Eng C 40:164–171

Armini S, Vakarelski IU, Whelan CM, Maex K, Higashitani K (2007a) Nanoscale indentation of polymer and composite polymer-silica core-shell submicrometer particles by atomic force microscopy. Langmuir 23:2007–2014

Armini S, Whelan CM, Maex K, Hernandez JL, Moinpour M (2007b) Composite polymer core-silica shell abrasive particles during oxide CMP: a defectivity study. J Electrochem Soc 154:H661–H671

Armini S, De Messemaeker J, Whelan CM, Moinpour M, Maex K (2008) Composite polymer core-ceria shell abrasive particles during oxide CMP: a defectivity study. J Electrochem Soc 155:H653–H660

Bahri MA, Hoebeke M, Grammenos A, Delanaye L, Vandewalle NS, Seret A (2006) Investigation of SDS, DTAB and CTAB micelle microviscosities by electron spin resonance. Colloid Surf A 290:206–212

Chen M, Zhou S, Wu L, Xie S, Chen Y (2005) Preparation of silica-coated polystyrene hybrid spherical colloids. Macromol Chem Phys 206:1896–1902

Chen Y, Long RW, Chen ZG (2011a) Polishing behavior of PS/CeO2 hybrid microspheres with controlled shell thickness on silicon dioxide CMP. Appl Surf Sci 527:8679–8685

Chen Y, Lu JX, Chen ZG (2011b) Preparation, characterization and oxide CMP performance of composite polystyrene-core ceria-shell abrasives. Microelectron Eng 88:200–205

Chen X, Zhao Y, Wang Y (2012a) Modeling the effects of particle deformation in chemical mechanical polishing. Appl Surf Sci 258:8469–8474

Chen Y, Mu WB, Lu JX (2012b) Young’s modulus of PS/CeO2 composite with core/shell structure microspheres measured using atomic force microscopy. J Nanopart Res 14:696

Chen A, Mu W, Chen Y (2014) Compressive elastic moduli and polishing performance of non-rigid core/shell structured PS/SiO2 composite abrasives evaluated by AFM. Appl Surf Sci 290:433–439

Chen Y, Qian C, Miao N (2015) Atomic force microscopy indentation to determine mechanical property for polystyrene-silica core-shell hybrid particles with controlled shell thickness. Thin Solid Films 579:57–63

Domínguez C, Rodríguez JA, Muñoz JF, Zine N (1999) The effect of rapid thermal annealing on properties of plasma enhanced CVD silicon oxide films. Thin Solid Films 346:202–206

Fleming MS, Mandal TK, Walt DR (2001) Nanosphere-microsphere assembly: methods for core-shell materials preparation. Chem Mater 13:2210–2216

Guo D, Xie G, Luo J (2014) Mechanical properties of nanoparticles: basics and applications. J Phys D Appl Phys 47:013001–013025

Ilie F (2012) Models of nanoparticles movement, collision, and friction in chemical mechanical polishing (CMP). J Nanopart Res 14:752

Ilie F (2013) Tribochemical interaction between nanoparticles and surfaces of selective layer during chemical mechanical polishing. J Nanopart Res 15:1997

Jauffrès D, Yacou C, Verdier M, Dendievel R, Ayral A (2011) Mechanical properties of hierarchical porous silica thin films: experimental characterization by nanoindentation and finite element modeling. Microporous Mesoporous Mater 140:120–129

Joo JB, Park J, Yi J (2009) Preparation of polyelectrolyte-functionalized mesoporous silicas for the selective adsorption of anionic dye in an aqueous solution. J Hazard Mater 168:102–107

Krishnan M, Nalaskowski JW, Cook LM (2010) Chemical mechanical planarization: slurry chemistry. Mater Mech Chem Rev 110:178–204

Kumar K, Nandan B, Luchnikov V, Simon F, Vyalikh A, Scheler U, Stamm M (2009) A novel approach for the fabrication of silica and silica/metal hybrid microtubes. Chem Mater 21:4282–4287

Lei J, Wang L, Zhang J (2011) Superbright multifluorescent core-shell mesoporous nanospheres as trackable transport carrier for drug. ACS Nano 5:3447–3455

Lei H, Wu X, Chen R (2012) Preparation of porous alumina abrasives and their chemical mechanical polishing behavior. Thin Solid Films 520:2868–2872

Li H, Lei H, Chen R (2012) Preparation of porous Fe2O3/SiO2 nanocomposite abrasives and their chemical mechanical polishing behaviors on hard disk substrates. Thin Solid Films 520:6174–6178

Li X, Zhou L, Wei Y, El-Toni AM, Zhang F, Zhao D (2014) Anisotropic growth induced synthesis of dual-compartment janus mesoporous silica nanoparticles for bimodal triggered drugs delivery. J Am Chem Soc 136:15086–15092

Miller MS, Ferrato MA, Niec A, Biesinger MC, Carmichael TB (2014) Ultrasmooth gold surfaces prepared by chemical mechanical polishing for applications in nanoscience. Langmuir 30:14171–14178

Ran Z, Sun Y, Chang B, Ren Q, Yang W (2013) Silica composite nanoparticles containing fluorescent solid core and mesoporous shell with different thickness as drug carrier. J Colloid Interface Sci 410:94–101

Roa JJ, Gastón-García B, García-Lecina E, Müller C (2012) Mechanical properties at nanometric scale of alumina layers formed in sulphuric acid anodizing under burning conditions. Ceram Int 38:1627–1633

Sannino F, Ruocco S, Marocco A, Esposito S, Pansini M (2013) Simazine removal from waters by adsorption on porous silicas tailored by sol-gel technique. Microporous Mesoporous Mater 180:178–186

Sarı A, Alkan C, Döğüşcü DK, Kızıl Ç (2015) Micro/nano encapsulated n-tetracosane and n-octadecane eutectic mixture with polystyrene shell for low-temperature latent heat thermal energy storage applications. Sol Energy 115:195–203

Sau TK, Murphy CJ (2005) Self-assembly patterns formed upon solvent evaporation of aqueous cetyltrimethylammonium bromide-coated gold nanoparticles of various shapes. Langmuir 21:2923–2929

Shibuy K, Nagao D, Ishii H, Konno M (2014) Advanced soap-free emulsion polymerization for highly pure, micronsized, monodisperse polymer particles. Polymer 55:535–539

Wang DP, Zeng HC (2011a) Creation of interior space, architecture of shell structure, and encapsulation of functional materials for mesoporous SiO2 spheres. Chem Mater 23:4886–4899

Wang S, Zhang M, Wang D, Zhang W, Liu S (2011b) Synthesis of hollow mesoporous silica microspheres through surface sol-gel process on polystyrene-co-poly (4-vinylpyridine) core-shell microspheres. Microporous Mesoporous Mater 139:1–7

Williford RE, Li XS, Addleman RS, Fryxell GE, Baskaran S, Birnbaum JC, Coyle C, Zemanian TS, Wang C, Courtney AR (2005) Mechanical stability of templated mesoporous silica thin films. Microporous Mesoporous Mater 85:260–266

Yang M, Wang G, Yang Z (2008) Synthesis of hollow spheres with mesoporous silica nanoparticles shell. Mater Chem Phys 111:5–8

Yang Y, Liu J, Li X, Liu X, Yang Q (2011) Organosilane-assisted transformation from core-shell to yolk-shell nanocomposites. Chem Mater 23:3676–3684

Acknowledgments

The work was supported financially by the National Natural Science Foundation of China (51205032, 51405038, and 51575058).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Y., Qin, J., Wang, Y. et al. Core/shell composites with polystyrene cores and meso-silica shells as abrasives for improved chemical mechanical polishing behavior. J Nanopart Res 17, 363 (2015). https://doi.org/10.1007/s11051-015-3172-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-015-3172-5