Abstract

Underground coal gasification (UCG) is an advancing technology that is receiving considerable global attention as an economic and environmentally friendly alternative for exploitation of coal deposits. UCG has the potential to decrease greenhouse gas emissions (GHG) during the development and utilization of coal resources. In this paper, the life cycle of UCG from in situ coal gasification to utilization for electricity generation is analyzed and compared with coal extraction through conventional coal mining and utilization in power plants. Four life cycle assessment models have been developed and analyzed to compare (greenhouse gas) GHG emissions of coal mining, coal gasification and power generation through conventional pulverized coal fired power plants (PCC), supercritical coal fired (SCPC) power plants, integrated gasification combined cycle plants for coal (Coal-IGCC), and combined cycle gas turbine plants for UCG (UCG-CCGT). The analysis shows that UCG is comparable to these latest technologies and in fact, the GHG emissions from UCG are about 28 % less than the conventional PCC plant. When combined with the economic superiority, UCG has a clear advantage over competing technologies. The comparison also shows that there is considerable reduction in the GHG emissions with the development of technology and improvements in generation efficiencies.

Similar content being viewed by others

References

Ag Mohamed A, Batto SF, Changmoon Y et al (2011) Viability of underground coal gasification with carbon capture and storage in Indiana. Capstone Design, Bloomington School of Public and Environmental Affairs, Indiana University

Anon (1977) In situ coal-gasification. Compressed Air 82(1):14–15

Association of American Railroads (2010) Railroads and coal. www.aar.org/~/media/aar/backgroaundpapers/railroadsandcoal.ashx. Cited 21 May 2012

Association of American Railroads (2011) Railroads and coal. www.aar.org/~/media/aar/Background…/Railroads-and-Coal.ashx. Cited 21 May 2012

Association of American Railroads (2012) The environmental benefits of moving freight by rail. http://www.aar.org/KeyIssues/~/media/aar/Background-Papers/The-Environmental-Benefits-of-Rail.ashx. Cited 21 May 2012

Baumann H, Tillman A-M (2004) The hitch hiker’s guide to LCA: an orientation in life cycle assessment methodology and application. Studentlitteratur, Lund Sweden

Blinderman MS (2004) Underground coal gasification for power generation: efficiency and CO2 emissions. In: Proceedings of ASME power, April 2004

Blinderman MS, Jones RM (2002) The Chinchilla IGCC project to date: Underground coal gasification and environment. Paper presented at the 2002 gasification technologies conference, San Francisco USA, 27–30 October 2002

Blodgett S, Kuipers JR (2002) Underground hard-rock mining: subsidence and hydrologic environmental impacts. Center for Science in Public Participation, Bozeman

Burton E, Friedmann J, Upadhye R (2006) Best practices in underground coal gasification. Lawrence Livermore National Laboratory, U.S. Department of Energy (available via http://www.purdue.edu/discoverypark/energy/pdfs/cctr/BestPracticesinUCG-draft.pdf)

Courtney R (2009) Underground coal gasification. Paper presented at the UCG workshop, 26th annual international Pittsburgh coal conference, Pittsburgh PA, 20–23 September 2009

Creedy DP, Garner K, Holloway S et al (2001) Review of underground coal gasification technological advancements. COAL R211, DTI/Pub URN 01/1041. Department of Trade & Industry UK

DEAT (2004) Life cycle assessment, integrated environmental management, information series 9. Department of Environmental Affairs and Tourism (DEAT), Pretoria South Africa

DiPietro P (2010) Life cycle analysis of coal and natural gas-fired power plants. National Energy Technology Laboratory U.S. Department of Energy Electric Power Research Institute (EPTI) Coal Fleet May 19, 2012

Ditsele O, Awuah-Offei K (2010) Estimating life cycle greenhouse gas emissions for a surface coal mine. In: Proceedings of SME annual meeting and exhibit 2010, Phoenix AZ, 28 February- 3 March 2010

Dones R, Bauer C, Heck T (2008) LCA of current coal, gas and nuclear electricity systems and electricity mix in the USA. Paul Scherrer Institute, Switzerland

Donnelly CR, Carias A, Morgenroth M et al (2011) An assessment of the life cycle costs and GHG emissions for alternative generation technologies. Ontario, Canada

DoS (2010) U.S. climate action report. U.S. Department of State Global Publishing Services, Washington

DOT (2011a) National transportation statistics 2011, Table 4–25: energy intensity of class-1 railroad freight service. U.S. Department of Transportation-Bureau of Transportation Statistics Washington DC (available via http://www.bts.gov/publications/national_transportation_statistics/)

DOT (2011b) National transportation statistics 2011, Table 4–17: class I rail freight fuel consumption and travel. U.S. Department of Transportation-Bureau of Transportation Statistics Washington DC (available via http://www.bts.gov/publications/national_transportation_statistics/)

Draucker L, Bhander R, Bennet B et al (2010) Life cycle analysis: supercritical pulverized coal (SCPC) power plant. DOE/NETL-403-110609. National Energy Technology Laboratory (NETL) U.S. Department of Energy, prepared by Research and Development Solutions, LLC

EERE (2002) Mining industry of the future: energy and environmental profile of the U.S. mining industry. Office of Energy Efficiency and Renewable Energy (EERE) U.S. Department of Energy BCS Incorporated, (available via http://www1.eere.energy.gov/manufacturing/industries_technologies/mining.html) Cited 6 June 2012

EIA (2008) Issues in focus, annual energy outlook 2007: coal transportation issues. U.S. Energy Information Administration (available via http://www.eia.gov/oiaf/aeo/otheranalysis/cti.html)

EIA (2009) National trends in coal transportation: modal shares of utility contract coal tonnage, 1979, 1987, 1995, and 1997. U.S. Energy Information Administration (available via http://www.eia.gov/cneaf/coal/ctrdb/natltrends.html) Cited April 2012

EIA (2011) Annual coal distribution report 2010. U.S. Energy Information Agency (available via http://www.eia.gov/coal/distribution/annual/) Cited May 2012

EIA (2012a) U.S. coal reserves (2010). U.S. Energy Information Administration

EIA (2012b) Annual energy release 2012, early release overview. U.S. Energy Information Administration (available via http://www.eia.gov/forecasts/aeo/er/pdf/0383er%282012%29.pdf)

EPA (1995) Emission factor documentation for AP-42, Section 11.10: coal cleaning final report. EPA Contract 68-D2-0159, Work Assignment No. II-01, MRI Project No. 4602-01. Office of Air Quality Planning and Standards Emission Factor and Inventory Group U. S. Environmental Protection Agency Research Triangle Park North Carolina, USA

EPA (1999) U.S. methane emissions 1990–2020: inventories, projections, and opportunities for reductions. Washington DC U.S. Environmental Protection Agency, Office of Air and Radiation (available via http://epa.gov/methane/reports/methaneintro.pdf)

EPA (2010) Greenhouse gas emissions reporting from the petroleum and natural gas industry, background technical support document. U.S. Environmental Protection Agency Climate Change Division Washington DC (avaialable via http://www.epa.gov/climatechange/emissions/downloads10/Subpart-W_TSD.pdf)

EPA (2012) Inventory of U.S. greenhouse gas emissions and sinks: 1990–2010. EPA 430-R-12-001. U.S. Environmental Protection Agency Washington DC

Federal Railroad Administration (2009) Comparative evaluation of rail and truck fuel efficiency on competitive corridors. U.S. Department of Transportation office of Policy and Communication Washington DC

Fergusson KJ (2009) A cleaner, cheaper, indigenous fuel for combined cycle plants. Mod Pow Sys 29(8):24–26

Finnveden G, Hauschild MZ, Ekvall T et al (2009) Recent developments in life cycle assessment. J Environ Manag 91(1):1–21

Fiscor S (2011) U.S. prep plant census. In: Coal Age (available via. http://www.coalage.com/index.php/features/1450-us-prep-plant-census.html)

Fiscor SJ (2000) Prep plant population reflects industry. Coal Age 105(10):31

Forster P, Ramaswamy V, Artaxo P et al (2007) Changes in atmospheric constituents and in radiative forcing. Contribution of Working Group I to the Fourth Assessment report of the Intergovernmental Panel on Climate Change, vol The Physical Science Basis. Cambridge University Press, Cambridge United Kingdom and New York USA

Fulton M, Mellquits N, Kitasei S et al (2011) Comparing life-cycle greenhouse gas emissions from natural gas and coal. Deutsche Bank Group DB climate change advisors, Prepared by World Watch Institute, Frankfurt

George FC, Alvarez R, Campbell G et al (2011) Life-cycle emissions of natural gas and coal in the power sector. In: Working document of the NPC North American resource development study by the Life-cycle analysis team of the carbon and other end-use emissions subgroup, National Petroleum Council (NPC)

Ghose MK, Paul B (2007) Underground coal gasification: a neglected option. Int J Environ Stud 64:777–783

Hoffmann BS, Szklo A (2011) Integrated gasification combined cycle and carbon capture: a risky option to mitigate CO2 emissions of coal-fired power plants. Appl Energ 88(11):3917–3929

Howarth R, Santoro R, Ingraffea A (2011) Methane and the greenhouse-gas footprint of natural gas from shale formations. Clim Chang 106(4):679–690

Hughes DJ (2011) Life cycle greenhouse gas emissions from shale gas compared to coal: an analysis of two conflicting studies. Post Carbon Institute, Santa Rosa California

Hyder Z, Ripepi N, Karmis M (2012) Underground coal gasification in the central Appalachian region, USA: resource assessment. Paper presented at the 22nd world mining congress and expo, Istanbul Turkey, 11–16 September 2012

IEA (2011) World energy outlook 2011, Factsheet. International Energy Agency Paris, France

International Standards Organization (2006) Management environnemental: analyse du cycle de vie: principes et cadre (Environmental management: life cycle assessment: principles and framework). ISO 14040(Second edition), Genève Switzerland

ITP (2007) Mining industry energy bandwidth study. Industrial technologies program: Energy Efficiency and Renewable Energy (EERE) U.S. Department of Energy, BCS Incorporated (available via http://www1.eere.energy.gov/manufacturing/industries_technologies/mining/pdfs/mining_bandwidth.pdf) Cited 12 May 2012

Jaramillo P (2007) A life cycle comparison of coal and natural gas for electricity generation and the production of transportation fuels. Dissertation, Carnegie Mellon University

Jaramillo P, Griffin MW, Matthews SH (2005) Comparative life cycle carbon emissions of LNG versus coal and gas for electricity generation. Civil and Environmental Engineering, Carnegie Mellon University, Pittsburgh PA http://www.ce.cmu.edu/~gdrg/readings/2005/10/12/Jaramillo_LifeCycleCarbonEmissionsFromLNG.pdf. Cited 25 August 2012

Jaramillo P, Griffin WM, Matthews HS (2007) Comparative life-cycle air emissions of coal, domestic natural gas, LNG, and SNG for electricity generation. Environ Sci Technol 41(17):6290–6296

Kurose R, Makino H, Suzuki A (2004) Numerical analysis of pulverized coal combustion characteristics using advanced low-NOX burner. Fuel 83(6):693–703

Lockwood AH, Welker-Hood K, Rauch M et al (2009) Coal’s assault on human health. In: A report from physicians for social responsibility, (available via. http://www.psr.org/assets/pdfs/psr-coal-fullreport.pdf)

McIntyre J, Berg B, Seto H et al. (2011) Comparison of lifecycle greenhouse gas emission of various electricity generation sources. World Nuclear Association (WNA), London UK (available via http://www.world-nuclear.org/uploadedFiles/org/WNA/Publications/Working_Group_Reports/comparison_of_lifecycle.pdf) Cited 19 May 2012

Meany RA, Maynard A (2009) A review of the potential for underground coal gasification and gas to liquids applications in Pedirka basin, Onshore Northern territory and Pela 77 Pedirka basin, Onshore South Australia. Mulready Consulting Services Pty Ltd, Australia

Moorhouse J, Huot M, McCulloch M (2010) Underground coal gasification: environmental risks and benefits. In: Roberta F (ed) The Pembina institute, Drayton Valley Alberta

Nalbandian H (2009) Performance and risks of advanced pulverized-coal plants. Energeia 20(1):2

National Mining Association (2011) Most requested statistics - U.S. coal industry. NMA, Washington DC http://www.nma.org/pdf/c_most_requested.pdf. Cited June 2012

PACE (2009) Life cycle assessment of GHG emissions from LNG and coal fired generation scenarios: assumptions and results. Prepared for: Center for liquefied natural gas (CLNG), Virginia USA

Power 4 Georgians (2008) Supercritical power plants. http://power4georgians.com/supercritical.aspx. Cited 15 August 2012

Pre Consultants (2010) SimaPro 7. Netherlands

Ray SK, Panigrahi DC, Ghosh AK (2010) Cleaner energy production with underground coal gasification - a review. J Inst Engr (India) 91:3–9

Rebitzer G, Ekvall T, Frischknecht R et al (2004) Life cycle assessment: part 1: framework, goal and scope definition, inventory analysis, and applications. Environ Int 30(5):701–720

Reddy BV (2010) Biomass and coal gasification based advanced power generation systems and recent research advances. In: Proceedings of the 37th national & 4th international conference on fluid mechanics and fluid power, IIT Madras India, 16–18 December 2010

Ruether JA, Ramezan M, Balash PC (2004) Greenhouse gas emissions from coal gasification power generation systems. J Infrastruct Syst 10(3):111–119

Shafirovich E, Varma A (2009) Underground coal gasification: a brief review of current status. Ind Eng Chem Res 48(17):7865–7875

Shindell DT, Faluvegi G, Koch DM et al (2009) Improved attribution of climate forcing to emissions. Science 326(5953):716–718

Skone TJ (2011) Life cycle greenhouse gas analysis of natural gas extraction & delivery in the United States. National Energy Technology Laboratory (NETL) U.S. Department of Energy, Presented at: Cornell University Lecture Series

Spath PL, Mann MK, Kerr DR (1999) Life cycle assessment of coal-fired power production. NREL/TP-570-25119. Campbell G (ed) National Renewable Energy Laboratory, Golden Colorado

United Nations (1998) Kyoto protocol. United Nations Framework Convention on Climate Change (UNFCC)

University of Wyoming (2001) The Wyoming coal website, Moving coal: the unit train. http://www.wsgs.uwyo.edu/coalweb/trains/unit.aspx. Cited 15 August 2012

Vipperman JS, Bauer ER, Babich DR (2007) Survey of noise in coal preparation plants. J Acoust Soc Am 121(1):197–205

Walker L (1999) Underground coal gasification: a clean coal technology ready for development. Austra Coal Rev: 19–21

World Coal Association (2011) Uses of coal. http://www.worldcoal.org/coal/uses-of-coal/. Cited 1st June 2012

World Coal Association (2012) Improving efficiencies. http://www.worldcoal.org/coal-the-environment/coal-use-the-environment/improving-efficiencies/. Cited 21 June 2012

Yang L, Zhang X, Liu S et al (2008) Field test of large-scale hydrogen manufacturing from underground coal gasification (UCG). Int J Hydrog Energy 33(4):1275–1285

Young P (2011) Annual coal report 2010. DOE/EIA-0584(2010). U.S. Energy Information Administration (EIA), Washington DC (available via. http://205.254.135.7/coal/annual/pdf/acr.pdf)

Zorya A, Alexander K, Efim K (2009) Underground coal gasification: its application for production of difficult to recover fuels. Paper presented at the 24th world gas conference Buenos Aires Argentina, 5–9 October 2009

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendices

1.1 Appendix 1: Energy requirements for underground coal mine

Equipment and Energy requirement for a hypothetical U.S. Underground coal mine with a production rate of 3,322 ton/day based on EERE data | ||||||

Equipment | Daily utilization | Energy Consumption | ||||

Single Unit | All Units | All Units | All Units | |||

Type | number of units | hours/unit | (Btu/ton) | (Btu/ton) | (Btu/hour) | (Btu/day) |

Electrical Equipment | ||||||

Main Fans | 11 | 18 | 11,900 | 130,900 | 24,158,322 | 434,849,800 |

LHD | 25 | 18 | 2,340 | 58,500 | 10,796,500 | 194,337,000 |

Drills | 13 | 18 | 317 | 4,121 | 760,553 | 13,689,962 |

Two Booms Jumbo | 20 | 18 | 1,740 | 34,800 | 6,422,533 | 115,605,600 |

Continuous Mining Machine | 2 | 18 | 8,740 | 17,480 | 3,226,031 | 58,068,560 |

Raise Borer | 1 | 18 | 4,690 | 4,690 | 865,566 | 15,580,180 |

Diamond Drill | 1 | 0.36 | 6 | 6 | 55,367 | 19,932 |

Crusher | 1 | 18 | 1,760 | 1,760 | 324,818 | 5,846,720 |

Conveyor | 1 | 18 | 2,370 | 2,370 | 437,397 | 7,873,140 |

Water Pumps | 2 | 18 | 72 | 144 | 26,576 | 478,368 |

Diesel Equipment | ||||||

Roof Bolter | 1 | 18 | 1,280 | 1,280 | 236,231 | 4,252,160 |

Service Trucks | 31 | 18 | 1,840 | 57,040 | 10,527,049 | 189,486,880 |

ANFO Loaders | 6 | 18 | 1,840 | 11,040 | 2,037,493 | 36,674,880 |

Total | 324,131 | 59,874,436 | 1,076,763,182 | |||

1.2 Appendix 2: Energy requirements for surface coal mine

Equipment and Energy requirement for a hypothetical U.S. surface coal mine with a production rate of 27,778t/day based on EERE data | ||||||

Equipment | Daily utilization | Energy Consumption | ||||

Single Unit | All Units | All Units | All Units | |||

Type | (number of units) | hours/unit | (Btu/ton) | (Btu/ton) | (Btu/hour) | (Btu/day) |

Diesel Equipment | ||||||

Rear Dump Trucks | 11 | 20 | 2,370 | 26,070 | 36,208,623 | 724,172,460 |

Bull Dozers | 7 | 20 | 1,680 | 11,760 | 16,333,464 | 326,669,280 |

Pickup Trucks | 20 | 20 | 149 | 2,980 | 4,138,922 | 82,778,440 |

Water Tankers | 1 | 20 | 1,080 | 1,080 | 1,500,012 | 30,000,240 |

Pumps | 2 | 20 | 332 | 664 | 922,230 | 18,444,592 |

Service Trucks | 2 | 20 | 293 | 586 | 813,895 | 16,277,908 |

Bulk Trucks | 2 | 20 | 293 | 586 | 813,895 | 16,277,908 |

Graders | 1 | 1 | 52 | 52 | 1,203,713 | 1,444,456 |

Electrical Equipment | ||||||

Cable Shovels | 4 | 20 | 2,490 | 9,960 | 13,833,444 | 276,668,880 |

Rotary Drills | 2 | 20 | 813 | 1,626 | 2,258,351 | 45,167,028 |

Total | 55,364 | 78,026,550 | 1,537,901,192 | |||

1.3 Appendix 3: Energy and material requirements for UCG

Data for UCG | |

Calorific value of coal | 26.4 MJ/kg |

Calorific value of Gas | 5.0 MJ/m3 |

Turbine efficiency | 50 % |

Plant Capacity | 300 MW |

Operating capacity factor | 80 % |

Coal resource recovery | 75 % |

Total plant life | 20 years |

Coal requirement | 1, 650,000 ton/year |

Gas requirements | 3,784,320,000 m3/year |

Water | 2.33 × 106 m3/year |

Copper ore (for wiring, generators) | 234 ton/year |

Oil | 4,467.60 GJ/year |

UCG electrical consumption | 8.47 MW |

1.4 Appendix 4: Energy requirements for coal preparation plant

Energy required for coal preparation plant with a feed rate of 3,332 t per day or 185 t per hour, based on EERE data | ||||||

Equipment | Daily utilization | Energy Consumption | ||||

Single Unit | All Units | All Units | All Units | |||

Type | (number of units) | hours/unit | (Btu/ton) | (Btu/ton) | (Btu/hour) | (Btu/day) |

Grinding Mill | 1 | 18 | 93,200 | 93,200 | 17,200,578 | 309,610,400 |

Centrifuge | 1 | 18 | 585 | 585 | 107,965 | 1,943,370 |

Flotation Machine | 1 | 18 | 359 | 359 | 66,255 | 1,192,598 |

Screens | 1 | 18 | 238 | 238 | 43,924 | 790,636 |

Magnetic Separator | 1 | 18 | 121 | 121 | 22,331 | 401,962 |

Total | 94,503 | 17,441,054 | 313,938,966 | |||

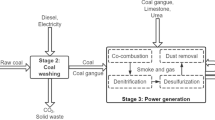

1.5 Appendix 5: Life cycle components: Coal production

The model shows the coal production component of life cycle GHG emissions for electricity generation from coal plants. The GHG emissions are calculated as kgCO2eq per ton of mined coal using GWP values estimated by 2007 IPCC for 100-year timeframe. 69 % coal is from surface mines and 31 % is from underground coal mines, representing the U.S. average. This part is common for PCC, SCPC, and Coal-IGCC, as it calculates emission per ton of coal, not for the coal requirements for the plant.

1.6 Appendix 6: Life cycle components: Coal processing

The model shows the coal-processing component of life cycle GHG emissions for electricity generation from coal plants. The GHG emissions are calculated as kgCO2eq per ton of processed coal using GWP values estimated by 2007 IPCC for 100-year timeframe. This part is common for PCC, SCPC, and Coal-IGCC, as it calculates emissions per ton of coal, not for the coal requirements for the plant.

1.7 Appendix 7: Life cycle components: Coal transport

This model shows life cycle GHG emissions from coal transport component. The GHG emissions are calculated as kgCO2eq per ton of transported coal using GWP values estimated by 2007 IPCC for 100-year timeframe. This part is common for PCC, SCPC and Coal-IGCC plants, as it calculates emission per ton of coal, not for the coal requirements for the plant. 75 % of coal is transported through trains, 15 % through barges, and 10 % through trucks representing the U.S. average for coal transportation.

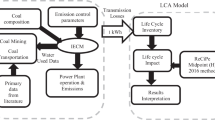

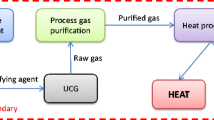

1.8 Appendix 8: Life cycle components: UCG production

This model shows life cycle GHG emissions from UCG production component. The GHG emissions are calculated as kgCO2eq per m3 of syngas using GWP values estimated by 2007 IPCC for 100-year timeframe. All the materials and energy flows, as well as emissions are attributed to 1 m3 syngas production.

1.9 Appendix 9: Life cycle components: UCG transport

This model shows life cycle GHG emissions from UCG transport. The GHG emissions are calculated as kgCO2eq per m3 of syngas using GWP values estimated by 2007 IPCC for 100-year timeframe. All the materials and energy flows, as well as emissions are attributed to 1 m3 syngas transport. The transport network for natural gas has been used in this model for UCG transportation.

Rights and permissions

About this article

Cite this article

Hyder, Z., Ripepi, N.S. & Karmis, M.E. A life cycle comparison of greenhouse emissions for power generation from coal mining and underground coal gasification. Mitig Adapt Strateg Glob Change 21, 515–546 (2016). https://doi.org/10.1007/s11027-014-9561-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11027-014-9561-8