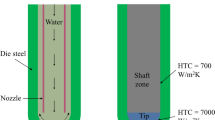

The paper describes the issues in predicting the consumer properties of thick-plate pipe products manufactured at the hot rolling mill 5000 of the Magnitogorsk Iron and Steel Works. The modeling of the thermal state of the billet on the mill train during the controlled rolling with subsequent accelerated cooling is also discussed.

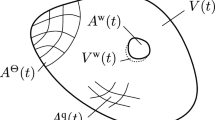

The work is mainly focused on the construction of a layer-by-layer cooling trajectory of the billet during accelerated cooling. Some results obtained by this model are compared with those of experimental rolling under the current conditions of the production facility.

Similar content being viewed by others

References

Steel Pipes for Wires in the Oil and Gas Industry. General Specifications, GOST ISO 3183–2015, replaced GOST of ISO 3183–2012; put in force 06/01/2016.

S. I. Platov, K. B. Maslennikov, V. L. Kornilov, V. A. Nekit, and N. V. Urtsev, “Aspects of microstructure prediction in the production of thick-plate pipe rolled products,” Proizvod. Prokata, No. 11, 6–12 (2019).

E. Weberberger, V. Zayruk, G. Mitter, and R. Konnert, “Increasing the productivity and product quality of the company’s broadband hot rolling mill,” Chern. Metally, No. 1, 26–32 (2008).

S. I. Platov, K. B. Maslennikov, and M. L. Lobanov, Technology for Predicting Strength Characteristics in the Production of Thick-Plate Pipe Rolled Products. Perspective Materials and Technologies, a monograph in 2 volumes, vol. 2, edited by the corresponding member V. V. Rubanik, UO VGTU, Vitebsk (2019).

A. R. Gareev, S. A. Murikov, S. I. Platov, V. N. Urtsev, and A. V. Shmakov, “Calculation of thermomechanical regimes and practical settings of the broadband hot rolling mill during experimental rolling of a complex rolled stock,” Proizvod. Prokata, No. 5, 14–17 (2015).

S. I. Platov, K. B. Maslennikov, and M. L. Lobanov, Influence of Thermomechanical Processing Parameters on the Microstructure of Thick-Plate Pipe Rolled Products, collection of writings of the international symposium Perspective Materials and Technologies, Vitebsk Gos. Tekhnologich. Univ., Vitebsk, 516–517 (2019).

S. P. Romanov, S. M. Gorbatyuk, I. G. Morozova, et al., Certificate 2021610620 RF. Certificate of State Registration of a Computer Program. Program for Automated Control of the Cooling System of Hot Rolling Mill Rolls, applicant National University of Science and Technology “MISiS”, No. 2020666350, appl. 12/10/2020; publ. 01/15/2021. Register of computer programs.

I. A. Artemiev, M. L. Krasnov, G. M. Rusakov, and S. V. Danilov, “Determination of thermal effects of diffusionless phase transformations in low-carbon low-alloy steels at high cooling rates,” Diagn. Res. Mech. Mater. Struct., No. 6, 173–183 (2018); https://doi.org/10.17804/2410-9908.2018.6.173-183.

S. I. Platov, R. R. Dema, and S. I. Lukyanov, “Development and implementation of technology for cooling rolling rolls in order to improve their performance on the broad-strip mill 2000 of Magnitogorsk Iron and Steel Works,” Vest. Magnitogorskogo Gos. Tekhn. Univ. G. I. Nosova, No. 2 (38), 100–101 (2012).

S. I. Platov, K. B. Maslennikov, N. V. Urtsev, et al., “Model of layer-by-layer cooling trajectory in rolled products by TMCP,” Mater. Sci. Forum, 1037, 390–399 (2021); https://doi.org/10.4028/www.scientific.net/MSF.1037.390.

I. V. Vier, A. V. Kozyulina, and S. A. Murikov, Mathematical Modeling of Temperature Fields in the Work Rolls of a Hot Rolling Mill, Proceedings Phase and Structural Transformations in Steels, No. 2, ed. V. N. Urtsev, Magnitogorsk, 374–384 (2002).

A. R. Gareev, A. V. Shmakov, S. A. Murikov, V. N. Urtsev, and D. Kh. Devyatov, “Creation of a software package for calculating the thermal state of metal in a hot-rolling-mill line,” Metallurgist, 55, Is. 11–12, 935–940 (2012).

S. A. Snitko, A. V. Yakovchenko, and S. M. Gorbatyuk, “Accounting method for residual technological stresses in modeling the stress-deformed state of a railway wheel disk. Report 2,” Izv. Ferr. Metall., 64(7), 477–483 (2021); https://doi.org/10.17073/0368-0797-2021-7-477-483.

E. A. Maksimov, R. L. Shatalov, “Mathematical model for calculating the parameters of straightening section profiles on a roller straightening machine,” Chernye Metally, No. 6, 14–18 (2021); https://doi.org/10.17580/chm.2021.06.03.

I. Pocebneva, Y. Deniskin, A. Yerokhin, V. Artiukh, and V. Vershinin, Simulation of an Aerodynamic Profile with Sections of ad hoc Concavity, E3S Web of Conf., 110, No. 01074 (2019); https://doi.org/10.1051/e3sconf/201911001074.

A. S. Smolyakov, S. I. Shakhov, and R. Kerimov, “Modernization of Baku Steel Company Metallurgical Plant Section CBCM for producing round pipe billets,” Metallurgist, 61, No. 7-8, 543–548 (2017); https://doi.org/10.1007/s11015-017-0530-9.

Y. V. Gamin, S. P. Galkin, B. A. Romantsev, A. N. Koshmin, A. V. Goncharuk, and M. V. Kadach, “Influence of radial-shear rolling conditions on the metal consumption rate and properties of D16 aluminum alloy rods,” Metallurgist, 65, No. 5-6, 650–659 (2021); https://doi.org/10.1007/s11015-021-01202-0.

A. N. Shapovalov, R. R. Dema, R. N. Amirov, and O. R. Latypov, “Improvement of the secondary cooling mode for continuous casting of round billets at Ural Steel JSC,” CIS Iron Steel Rev., 22, 15–19 (2021); https://doi.org/10.17580/cisisr.2021.02.03.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 66, No. 4, pp. 89–93, April, 2022. Russian DOI: https://doi.org/10.52351/00260827_2022_04_89.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Platov, S.I., Gorbatyuk, S.M., Lobanov, M.L. et al. Mathematical Model of the Accelerated Cooling of Metal in Thick-Plate Hot Rolling. Metallurgist 66, 462–468 (2022). https://doi.org/10.1007/s11015-022-01348-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-022-01348-5