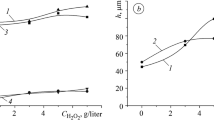

We study the effect of the coating thickness on the corrosion resistance and porosity of oxide-ceramic coatings on D16 alloy. The coatings were synthesized in an alkaline solution for 10, 60, and 120 min at a current density of 10 A/dm2 . As a result, the coatings with thicknesses of ∼ 8–12, 50–70, and 80–120 μm, respectively, were formed on the surface of the alloy. The corrosion resistance of the coatings was investigated in a medium of weakly acid rain and in a 3% NaCl solution in water. We established the correlation between the porosity and corrosion resistance of the coatings. The oxide-ceramic coatings synthesized on D16 alloy for 60 min have the lowest porosity and the highest corrosion resistance.

Similar content being viewed by others

References

T. Lampke, D. Meyer, G. Alisch, B. Wielage, H. Pokhmurska, M. Klapkiv, and M. Student, “Corrosion and wear behavior of alumina coatings obtained by various methods,” Mater. Sci.,46, No. 5, 591–598 (2011).

L. Wen, Ya. Wang, Y. Jin, B. Liu Yu Zhou, and D. Sun, “Microarc oxidation of 2024 Al alloy using spraying polar and its influence on microstructure and corrosion behavior,” Surf. Coat. Technol.,228, 92–99 (2013).

H. M. Nykyforchyn, V. I. Pokhmurskii, M. D. Klapkiv, M. M. Student, and J. Ippolito, “Electrochemical characteristics of PEO treated electric-arc coatings on lightweight alloys,” Adv. Mater. Research,138, 55–62 (2010).

M. M. Student, V. M. Posuvailo, H. H. Veselivs’ka, Ya. Ya. Sirak, and R. A. Yatsyuk, “Corrosion resistance of plasma-electrolytic layers on alloys and coatings of the Al–Cu–Mg system for various modes of heat treatment,” Fiz.-Khim. Mekh. Mater.,53, No. 6, 42–47 (2017); English translation: Mater. Sci.,53, No. 6, 789–795 (2018).

H. V. Pokhmurs’ka, M. D. Klapkiv, V. M. Posuvailo, S. Muecklich, and I. Ozdemir, “Electrochemical properties of the PEO coatings on AZ31 magnesium alloy produced by different technologies,” Fiz.-Khim. Mekh. Mater.,51, No. 1, 102–107 (2015); English translation: Mater. Sci.,51, No. 1, 114–120 (2015).

М. М. Student, V. V. Shmyrko, М. D. Klapkiv, І. M. Lyasota, and L. N. Dobrovol’ska, “Evaluation of the mechanical properties of combined metal-oxide-ceramic layers on aluminum alloys,” Fiz.-Khim. Mekh. Mater.,50, No. 2, 116–121 (2014); English translation: Mater. Sci.,50, No. 2, 290–295 (2014).

M. M. Student, V. М. Dovhunyk, М. D Klapkiv, V. M. Posuvailo, V. V. Shmyrko, and E. E. Kytsya, “Tribological properties of combined metal-oxide-ceramic layers on light alloys,” Fiz.-Khim. Mekh. Mater.,48, No. 2, 55–64 (2012); English translation: Mater. Sci.,48, No. 2, 180–190 (2012).

М. М. Student, V. M. Dovhunyk, V. M. Posuvailo, I. V. Koval’chuk, and V. M. Hvozdets’kyi, “Friction behavior of iron-carbon alloys in couples with plasma-electrolytic oxide-ceramic layers synthesized on D16T alloy,” Fiz.-Khim. Mekh. Mater.,53, No. 2, 63–70 (2017); English translation: Mater. Sci.,53, No. 2, 359–367 (2017).

J. A. Gonzales, V. Lopez, and A. Bautista, “Characterization of porous oxide films from a.c. impedance measurements,” J. Appl. Electrochem.,29, No. 2, 229–238 (1999).

W. Dietzel, M. Klapkiv, H. Nykyforchyn, V. Posuvailo, and C. Blawert, “Porosity and corrosion properties of electrolyte plasma coatings on magnesium alloys,” Fiz.-Khim. Mekh. Mater.,40, No. 5, 13–17 (2004); English translation: Mater. Sci.,40, No. 5, 585–590 (2004).

V. M. Posuvailo, M. D. Klapkiv, M. M. Student, H. V. Pokhmurska, and Y. Y. Sirak, “Gibbs energy calculation of electrolytic plasma channel with inclusions of copper and copper oxide with Al-base,” Mater. Sci. Eng.,181, 157–168 (2017).

J. A. Curran and T. W. Clyne, “Thermophysical properties of plasma electrolytic oxide coatings on aluminum,” Surf. Coat. Technol.,199, 168–176 (2005).

B. Rusyn, R. Tors’ka, and M. Kobasyar, “Application of the cellular automata for obtaining pitting images during simulation process of their growth,” Adv. Intell. System. Comput.,242, 299–306 (2014).

A. Y. Pokhmurs’kyi, B. P. Rusyn, and Y. V. Obukh, “Evaluation of the influence of pit-like defects on the strength of D16T sheet alloy,” Fiz.-Khim. Mekh. Mater.,48, No. 1, 95–99 (2012); English translation: Mater. Sci.,48, No. 1, 101–105 (2012).

Y. Zhang, W. Fan, H. Q. Du, and Y. W. Zhao, “Corrosion behavior and structure of plasma electrolytic oxidation coated aluminum alloy,” Int. J. Electrochem. Sci.,12, 6788–6800 (2017).

A. S. Shatrov, “Efficient systems of protection of the surfaces of products made of magnesium alloys. I. Formation and protective properties of oxide coatings,” Korros.: Mater., Zashch., No. 10, 31–40 (2006).

J. C. S. Fernandes, R. Picciochi, and M. Da Cunha Belo, “Capacitance and photoelectrochemical studies for the assessments of anodic oxide films on aluminum,” Electrochim. Acta.,49, 4701–4707 (2004).

J. A. Gonzales, S. Feliu, and A. Bautista, “Changes in cold sealed aluminum during ageing,” J. Appl. Electrochem.,29, No. 7, 845–854 (1999).

M. D. Klapkiv, Determination of the Physicochemical Parameters of the Process of Synthesis of Oxide Ceramic Coatings in an Electrolytic Plasma on Aluminum Alloys [in Ukrainian], Author’s Abstract of the Candidate Degree Thesis (Engineering), Lviv (1996).

I. B. Ivasenko, V. V. Botsyan, and R. A. Vorobel’, “Separation of the contours of subgrains in the images of 2.25Cr–1Mo steel by the method of division of overshoots,” Vidbir Obrob. Inform., Issue 36 (112), 98–102 (2012).

I. B. Ivasenko, V. M. Posuvailo, and M. D. Klapkiv, “Segmentation of pores in the images of oxide-ceramic coatings,” Vidbir Obrob. Inform., Issue 38 (114), 108–111 (2013).

I. B. Ivasenko, V. M. Posuvailo, M. D. Klapkiv, V. A. Vynar, and S. I. Ostap’yuk, “Express method for determining the presence of defects on the surfaces of oxide-ceramic coatings,” Fiz.-Khim. Mekh. Mater.,45, No. 3, 123–127 (2009); English translation: Mater. Sci.,45, No. 3, 460–464 (2009).

I. B. Ivasenko, V. M. Posuvailo, M. M. Student, H. H. Veselivs’ka, Y. Y. Sirak, Yu. M. Koval’, and N. Yu. Imbirovych, “The influence of microstructure on the corrosion defects of the surfaces of electric-arc coatings from the Al–Mn wires in the initial state and with plasma-electrolytic coatings,” Nauk. Notat., Issue 54, 141–145 (2016).

M. D. Klapkiv, H. M. Nykyforchyn, and V. M. Posuvailo, “Spectral analysis of an electrolytic plasma in the process of synthesis of aluminum oxide,” Fiz.-Khim. Mekh. Mater.,30, No. 3, 70–81 (1994); English translation: Mater. Sci.,30, No. 3, 333–343 (1995).

T. B. Van, S. D. Brown, and G. P. Wirtz, “Mechanism of anodic spark deposition,” Amer. Ceram. Soc. Bull.,56, No. 6, 563–568 (1977).

W. Krysmann, P. Kurze, K.-H. Dittrich, and H. G. Schneider, “Process characteristics and parameters of anodic oxidation by spark discharge (ANOF),” Crystal Res. Technol.,19, No. 7, 973–979 (1984).

V. T. Yavors’kyi, I. P. Mertsalo, M. D. Klapkiv, L. V. Savchuk, and V. T. Olynets’, “Influence of additions of water on the quality of filled anodic-oxide coatings,” Fiz.-Khim. Mekh. Mater.,39, No. 5, 114–117 (2003); English translation: Mater. Sci.,39, No. 5, 745–749 (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 54, No. 6, pp. 130–137, November–December, 2018.

Rights and permissions

About this article

Cite this article

Student, M.M., Ivasenko, I.B., Posuvailo, V.M. et al. Influence of the Porosity of a Plasma-Electrolytic Coating on the Corrosion Resistance of D16 Alloy. Mater Sci 54, 899–906 (2019). https://doi.org/10.1007/s11003-019-00278-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-019-00278-z