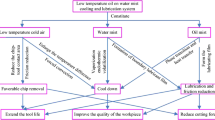

We study the morphology of chips formed in the course of turning of a blank of 38KhN3MFA steel on a turning lathe at a rotational speed of 200 rpm under the conditions without lubrication and with an addition of water or lubricating liquids (LL) containing sunflower oil. It was discovered that the addition of water and LL in the process of cutting promotes a decrease in the size of chip and leads to the transformation of its shape from flat to barrel-like. The application of LL makes the surface roughness nine times smaller than in the case of dry turning.

Similar content being viewed by others

References

Directive 2014/94/eu of the European Parliament and of the Council of 22 October 2014 on the Deployment of Alternative Fuels Infrastructure 2014/94/UE (EOG) L 307/1. – Access mode: https://eur-lex.europa.eu/search.html?qid=1536662083562&text=Directive%202014/94/eu%20of%20the%20European%20Parliament%20and%20of%20the%20Council&scope=EURLEX&type=quick&lang=en.

O. I. Balyts’kyi, V. O. Kolesnikov, Y. Eliasz, and M. R. Havrylyuk, “Specific features of the fracture of hydrogenated high-nitrogen manganese steels under conditions of rolling friction,” Fiz.-Khim. Mekh. Mater., 50, No. 4, 110–116 (2014); English translation: Mater. Sci., 50, No. 4, 604–611 (2015).

O. I. Balytskyi and V. O. Kolesnikov, “Investigation of wear products of austenitic manganese cast iron,” Fiz.-Khim. Mekh. Mater., 40, No. 1, 65–69 (2004); English translation: Mater. Sci., 40, No. 1, 78–82 (2004).

O. I. Balyts’kyi and V. O. Kolesnikov, “Investigation of wear products of high-nitrogen manganese steels,” Fiz.-Khim. Mekh. Mater., 45, No. 4, 93–98 (2009); English translation: Mater. Sci., 45, No. 4, 576–581 (2009).

О. О. Balyts’kyi, V. О. Kolesnikov, М. R. Havrylyuk, О. О. Pohorelov, and Е. B. Kolesnikova, A Method for Determining the Shape of Particle Surface After Dry and Hydrogen-Assisted Wear by a System of Computer Vision [in Ukrainian], Patent No. 108524 of Ukraine, Publ. on 25.07.2016, Bull. No. 14.

R. Maruda, G. Krolczyk, P. Nieslony, and S. Legutko, “Chip formation, zone analysis during the turning of austenitic stainless steel 316L under MQCL cooling condition,” Proc. Eng., No. 149, 297–304 (2016).

R. W. Maruda, S. Legutko, G. M. Krolczyk, and P. Raos, “Influence of cooling conditions on the machining process under MQCL and MQL conditions,” Tehnicki Vjesnik, 22, No. 4, 965–970 (2015).

R. W. Maruda, S. Legutko, G. M. Krolczyk, S. Hloch, and M. Michalski, “An influence of active additives on the formation of selected indicators of the condition of the X10CrNi18-8 stainless steel surface layer in MQCL conditions,” Int. J. Surf. Sci. Eng., No. 9, 452–465 (2015).

GOST 2789-73. Surface Roughness. Parameters and Characteristics [in Russian], Introduced 01.01.1975.

K. Nitzsche (editor), Testing of Metals [Russian translation], Metallurgiya, Moscow (1967).

R. K. Rajput, A Textbook of Manufacturing Technology (Manufacturing Processes), Boston, New Delhi (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 54, No. 5, pp. 103–107, September–October, 2018.

Rights and permissions

About this article

Cite this article

Balyts’kyi, О.І., Kolesnikov, V.О. & Havrylyuk, М.R. Influence of Lubricating Liquid on the Formation of the Products of Cutting of 38KhN3MFA Steel. Mater Sci 54, 722–727 (2019). https://doi.org/10.1007/s11003-019-00238-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-019-00238-7