Abstract

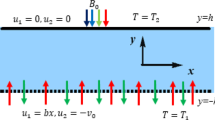

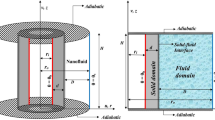

The paper communicates the flow, heat and mass transfer of a hybrid nanofluid (AA7072–AA7075/water) between the parallel plates, by incorporating chemical reactions, activation energy and heat source/sink effects. The governing partial differential equations are upgraded to ordinary differential equations by selecting relevant dimensionless variables and then are numerically resolved. Validation of the problem is confirmed between the present and existing work for the limiting cases and is found to be excellent concord. Moreover, the graphs are displayed to discuss the flow, heat and mass transport, friction drag, rate of heat and mass coefficient behaviour for different implanted parameters. It is noted that larger chemical reaction values minimize the concentration curve, while activation energy has the opposite pattern. Furthermore, upsurge values of heat source/sink parameter improve the rate of heat transport, but solid volume fraction reduces the drag friction. Also it has been discovered that AA7072–AA7075/water is a more efficient liquid than AA7072/water. Moving pistons, chocolate fillers, power transfer and compression are all examples of areas where the current research may be useful.

Similar content being viewed by others

Data availability

Availability exists for the data.

Abbreviations

- \(C\,\left( {{\text{mol}}\;{\text{m}}^{{ - 3}} } \right)\) :

-

Concentration

- \(C_{{\text{f}}} \,\left( - \right)\) :

-

Skin friction coefficient

- \(C_{H} \left( {{\text{mol}}\;{\text{m}}^{{ - 3}} } \right)\) :

-

Concentration at plate surface

- \(c_{{\text{p}}} \,\left( {{\text{Jkg}}^{{ - 1}} {\text{K}}^{{ - 1}} } \right)\) :

-

Specific heat capacity

- \(C_{{\text{W}}} \,\left( {{\text{mol}}\;{\text{m}}^{{ - 3}} } \right)\) :

-

Concentration at the wall

- \(D\,\,\left( {{\text{m}}^{2} {\text{s}}^{{ - 1}} } \right)\) :

-

Diffusion coefficient

- \(E\,\left( - \right)\) :

-

Activation energy parameter

- \(E_{{\text{a}}} \,\left( - \right)\) :

-

Activation energy

- \({\text{Hs}}\,\left( - \right)\) :

-

Heat source/sink parameter

- \(k\,\,\left( {{\text{Wm}}^{{ - 1}} {\text{K}}^{{ - 1}} } \right)\) :

-

Thermal conductivity

- \(k_{{\text{r}}} \,\left( - \right)\) :

-

Reaction rate

- \(K\,\left( - \right)\) :

-

Boltzmann constant

- \(n\,\left( - \right)\) :

-

Fitted rate constant

- \({\text{Nu}}\,\left( - \right)\) :

-

Nusselt number

- \(p\,\left( {{\text{Pa}}} \right)\) :

-

Pressure

- \(\Pr \,\left( - \right)\) :

-

Prandtl number

- \(Q\,\,\left( {{\text{Kgm}}^{{ - 1}} {\text{s}}^{{ - 3}} {\text{K}}^{{ - 1}} } \right)\) :

-

Uniform heat source/sink

- \({\text{Rc}}\,\left( - \right)\) :

-

Reaction rate parameter

- \({\text{Sc}}\,\left( - \right)\) :

-

Schmidt number

- \({\text{Sh}}\,\left( - \right)\) :

-

Sherwood number

- \(t\,\left( s \right)\) :

-

Time

- \(T\,\left( K \right)\) :

-

Fluid temperature

- \(T_{{\text{H}}} \,\left( K \right)\) :

-

Temperature of plate

- \(T_{{\text{W}}} \,\left( K \right)\) :

-

Temperature at the wall

- \(u,v\,\,\left( {{\text{ms}}^{{ - 1}} } \right)\) :

-

Velocity components

- \(x,y\,\left( m \right)\) :

-

Cartesian coordinates

- \(\rho \,\,\left( {{\text{kgm}}^{{ - 3}} } \right)\) :

-

Density

- \(\phi \,\left( - \right)\) :

-

Solid volume fraction

- \(\alpha \,\left( {s^{{ - 1}} } \right)\) :

-

Squeezing rate

- \(\mu \,\,\left( {{\text{kgm}}^{{ - 1}} {\text{s}}^{{ - 1}} } \right)\) :

-

Dynamic viscosity

- \(\eta \,\left( - \right)\) :

-

Similarity variable

- \(\delta \,\left( K \right)\) :

-

Temperature difference parameter

- \(f\,\,\,\) :

-

Fluid

- \({\text{nf}}\,\,\) :

-

Nanofluid

- \({\text{hnf}}\,\,\) :

-

Hybrid nanofluid

- \(\phi _{1} ,\;\phi _{2}\) :

-

Solid volume fraction of \({\text{AA}}7072\) and \({\text{AA}}7075\).

- \(s_{1}\) :

-

Solid nanoparticle \({\text{AA}}7072\)

- \(s_{2}\) :

-

Solid nanoparticle \({\text{AA}}7075\)

References

Gupta PS, Gupta AS. Squeezing flow between parallel plates. Wear. 1977;45:177–85.

Usman M, Zubair T, Hamid M, Haq RU. Novel modification in wavelets method to analyze unsteady flow of nanofluid between two infinitely parallel plates. Chin J Phys. 2020;66:222–36.

Roopa GS, Gireesha BJ, Bagewadi CS. Unsteady flow and heat transfer of a dusty fluid between two parallel plates. Int J Comput Sci Math. 2011;3:421–33.

Hatami M, Jing D, Song D, Sheikholeslami M, Ganji DD. Heat transfer and flow analysis of nanofluid flow between parallel plates in presence of variable magnetic field using HPM. J Magn Magn Mater. 2015;396:275–82.

Sheikholeslami M, Rashidi MM, Al Saad DM, Firouzi F, Rokni HB, Domairry G. Steady nanofluid flow between parallel plates considering thermophoresis and Brownian effects. J King Saud Univ Sci. 2016;28:380–9.

Akbar S, Hussain A. The influences of squeezed inviscid flow between parallel plates. Math Probl Eng. 2021;2021:e6647708.

Rashidi MM, Reza M, Gupta S. MHD stagnation point flow of micropolar nanofluid between parallel porous plates with uniform blowing. Powder Technol. 2016;301:876–85.

Narahari M, Fetecau C. Comparisons of the solutions obtained by two transform methods for motions of Newtonian fluids between parallel plates. Int J Appl Comput Math. 2020. https://doi.org/10.1007/s40819-020-0788-7.

Mehta T, Mehta R, Mehta A. Oscillatory fluid flow and heat transfer through porous medium between parallel plates with inclined magnetic field, radiative heat flux and heat source. Int J Appl Mech Eng. 2020;25:88–102.

Awan SE, Raja MAZ, Gul F, Khan ZA, Mehmood A, Shoaib M. Numerical computing paradigm for investigation of Micropolar nanofluid flow between parallel plates system with impact of electrical MHD and Hall current. Arab J Sci Eng. 2021;46:645–62.

Ramesh GK, Gireesha BJ. Influence of heat source/sink on a Maxwell fluid over a stretching surface with convective boundary condition in the presence of nanoparticles. Ain Shams Eng J. 2014;5:991–8.

Sheikholeslami M, Jafaryar M, Shafee A, Babazadeh H. Acceleration of discharge process of clean energy storage unit with insertion of porous foam considering nanoparticle enhanced paraffin. J Clean Prod. 2020;261:121206.

Sheikholeslami M, Farshad SA, Shafee A, Babazadeh H. Performance of solar collector with turbulator involving nanomaterial turbulent regime. Renew Energy. 2021;163:1222–37.

Rashad A, Chamkha AJ, El-Kabeir SMM. Effect of chemical reaction on heat and mass transfer by mixed convection flow about a sphere in a saturated porous media. Int J Numer Methods Heat Fluid Flow. 2011;21:418–33.

Jakeer S, BalaAnki Reddy P, Rashad AM, Nabwey HA. Impact of heated obstacle position on magneto-hybrid nanofluid flow in a lid-driven porous cavity with Cattaneo-Christov heat flux pattern. Alex Eng J. 2021;60:821–35.

Chamkha AJ, Yassen R, Ismael MA, Rashad AM, Salah T, Nabwey HA. MHD free convection of localized heat source/sink in hybrid nanofluid-filled square cavity. J Nanofluids. 2020;9:1–12.

Hsiao KL. To promote radiation electrical MHD activation energy thermal extrusion manufacturing system efficiency by using Carreau-Nanofluid with parameters control method. Energy. 2017;130:486–99.

Khan WA, Sultan F, Ali M, Shahzad M, Khan M, Irfan M. Consequences of activation energy and binary chemical reaction for 3D flow of Cross-nanofluid with radiative heat transfer. J Braz Soc Mech Sci Eng. 2019. https://doi.org/10.1007/s40430-018-1482-0.

Dhlamini M, Kameswaran PK, Sibanda P, Motsa S, Mondal H. Activation energy and binary chemical reaction effects in mixed convective nanofluid flow with convective boundary conditions. J Comput Des Eng. 2019;6:149–58.

Ijaz M, Ayub M. Nonlinear convective stratified flow of Maxwell nanofluid with activation energy. Heliyon. 2019;5: e01121. https://doi.org/10.1016/j.heliyon.2019.e01121.

Ramesh GK, Manjunatha S, Gireesha BJ. Impact of homogeneous-heterogeneous reactions in a hybrid nanoliquid flow due to porous medium. Heat Transfer. 2019;48:3866–84.

Sajid T, Tanveer S, Sabir Z, Guirao JLG. Impact of activation energy and temperature-dependent heat source/sink on Maxwell-Sutterby fluid. Math Probl Eng. 2020;2020:1–15. https://doi.org/10.1155/2020/5251804.

Madhukesh JK, Naveen Kumar R, Punith Gowda RJ, Prasannakumara BC, Ramesh GK, Ijaz Khan M, Khan SU, Chu YM. Numerical simulation of AA7072–AA7075/water-based hybrid nanofluid flow over a curved stretching sheet with Newtonian heating: a non-Fourier heat flux model approach. J Mol Liquids. 2021. https://doi.org/10.1016/j.molliq.2021.116103.

Kotresh MJ, Ramesh GK, Shashikala VKR, Prasannakumara BC. Assessment of Arrhenius activation energy in stretched flow of nanofluid over a rotating disc. Heat Transfer. 2021;50:2807–28.

El-Kabeir SMM, Chamkha AJ, Rashad AM. Effect of thermal radiation on Non-Darcy natural convection from a vertical cylinder embedded in a nanofluid porous media. J Porous Media. 2014;17:269–78.

Hayat T, Nadeem S. Heat transfer enhancement with Ag–CuO/water hybrid nanofluid. Res Phys. 2017;7:2317–24.

Ramesh GK, Roopa GS, Shehzad S, Khan SU. Interaction of Al2O3–Ag and Al2O3–Cu hybrid nanoparticles with water on convectively heated moving material. Multidiscip Model Mater Struct. 2020;16:1651–67.

Ramesh GK, Shehzad SA, Izadi M. Thermal transport of hybrid liquid over thin needle with heat sink/source and Darcy-Forchheimer porous medium aspects. Arab J Sci Eng. 2020;45:9569–78.

Rashad AM, Chamkha AJ, Ismael MA, Salah T. Magnetohydrodynamics Natural convection in a triangular cavity filled with a Cu–Al2o3/water hybrid nanofluid with localized heating from below and internal heat generation. J Heat Trans. 2018;140:072502.

Alsabery AI, Kadhim HT, Ismael MA, Hashim I, Chamkha AJ. Impacts of amplitude and heat source on natural convection of hybrid nanofluids into a wavy enclosure via heatline approach. Waves Random Complex Media. 2021. https://doi.org/10.1080/17455030.2021.1896819.

Ismael MA, Armaghani T, Chamkha AJ. Mixed convection and entropy generation in a lid-driven cavity filled by hybrid nanofluid and heated by triangular solid. Heat Transfer Res. 2018;49:1645–65.

Naduvinamani NB, Shankar U. Radiative squeezing flow of unsteady magneto-hydrodynamic Casson fluid between two parallel plates. J Cent South Univ. 2019;26:1184–204.

Mousavisani S, Khalesi J, Golbaharan H, Sepehr M, Ganji DD. Influence of inclined Lorentz forces through a porous media on squeezing Cu–H2O nanofluid in the presence of heat source/sink. Int J Numer Meth Heat Fluid Flow. 2020;30:2563–81.

Khan MI, Ahmad S, Hayat T, Alsaedi A. Entropy generation and activation energy impact on radiative flow of viscous fluid in presence of binary chemical reaction. Int J Chem Reactor Eng. 2018. https://doi.org/10.1515/ijcre-2018-0045.

Sheikholeslami M, Ganji DD. Heat transfer of Cu-water nanofluid flow between parallel plates. Powder Technol. 2013;235:873–9.

Khan U, Zaib A, Khan I, Baleanu D, Sherif E-SM. Comparative investigation on MHD nonlinear radiative flow through a moving thin needle comprising two hybridized AA7075 and AA7072 alloys nanomaterials through binary chemical reaction with activation energy. J Mater Res Technol. 2020;9:3817–28.

Ramesh GK, Aly EH, Shehzad SA, Abbasi FM. Bödewadt flow and heat transfer of hybrid nanomaterial. Int J Ambient Energy. 2020. https://doi.org/10.1080/01430750.2020.1818127.

Acknowledgements

The authors are thankful to the editor and referee for their encouraging comments and constructive suggestions to improve the presentation of this manuscript.

Funding

We do not have any sources of financial funding and support from government and private sector.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The content of paper has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramesh, G.K., Madhukesh, J.K., Prasannakumara, B.C. et al. Significance of aluminium alloys particle flow through a parallel plates with activation energy and chemical reaction. J Therm Anal Calorim 147, 6971–6981 (2022). https://doi.org/10.1007/s10973-021-10981-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10981-2