Abstract

Considering the expansion of heat pump systems as one of the environment-friendly cycles, increasing these cycles' efficiency is significant. This paper is a comprehensive study of transcritical CO2 heat pump cycles in heating and cooling modes covering a range of ambient temperatures from −15 to 30 °C along with the range of 25 to 45 °C in cases of gas-cooler exit temperatures. In this study, the ambient temperature of 0 °C and gas-cooler exit temperatures of 30 and 35 °C were examined, and the best Coefficient of Performance and exergy efficiency were obtained at a discharge pressure of 7496 and 8896 kPa, respectively. The ambient temperature of 30 °C and gas-cooler exit temperatures of 45 and 50 °C were investigated, and the discharge pressure of 10,938 and 12,363 kPa have the highest Coefficient of Performance and exergy efficiency, respectively. The results show that the gas-cooler temperature positively affects the optimum discharge pressure. In conclusion, an equation for Optimum Discharge Pressure is presented as a general correlation to obtain this parameter for the heating and cooling modes in these commonly used cycles. This equation also presented with a deviation less than 5.66% of the optimum discharge pressure obtained from energy and exergy analysis. Therefore, it has been identified as an acceptable criterion in these cycles. Furthermore, by examining the amount of exergy destruction of these cycles' most essential components, it becomes clear that they are the most exergy destruction related to the compressor.

Similar content being viewed by others

Abbreviations

- \(\mathop {Ex}\limits^{ \cdot }\) :

-

Exergy rate (kW)

- h:

-

Enthalpy (kJ kg−1)

- \(\mathop m\limits^{ \cdot }\) :

-

Mass flow rate (kg s−1)

- P:

-

Pressure (kPa)

- \(\mathop Q\limits^{ \cdot }\) :

-

Heat transfer (kW)

- S:

-

Specific entropy (kJ kg−1 K−1)

- T:

-

Temperature (K)

- \(W\) :

-

Power consumption (kW)

- \(\eta\) :

-

Efficiency

- 0:

-

Ambient

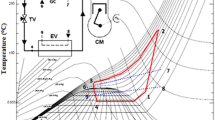

- 1–4:

-

State points in Fig. 1

- a:

-

Each point in Fig. 1

- mp:

-

Compressor

- dest:

-

Destruction

- eva:

-

Evaporator

- gc:

-

Gas-cooler

- is:

-

Isentropic

- COP:

-

Coefficient of performance

- ODP:

-

Optimal Discharge Pressure

References

Akbari M, Bidi M, Najafi A, Ahmadi M. Energy exergy analysis and performance evaluation of a vacuum evaporator for solar thermal power plant zero liquid discharge systems. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08463-7.

Shadloo MS. Application of support vector machines for accurate prediction of convection heat transfer coefficient of nanofluids through circular pipes. Int J Num Methods Heat Fluid Flow. 2020. https://doi.org/10.1108/HFF-09-2020-0555

Reilly A, Kinnane O. The impact of thermal mass on building energy consumption. Appl Energy. 2017;198:108–21. https://doi.org/10.1016/j.apenergy.2017.04.024.

Amiri Rad E, Maddah S, Mohammadi S. Designing and optimizing a novel cogeneration system for an office building based on thermo-economic and environmental analyses. Renew Energy. 2020;151:342–54. https://doi.org/10.1016/j.renene.2019.11.024.

Patel B, Kachhwaha SS, Modi B. Thermodynamic modelling and parametric study of a two stage compression-absorption refrigeration system for ice cream hardening plant. Energy Procedia. 2017;109:190–202. https://doi.org/10.1016/j.egypro.2017.03.091.

Homod RZ, Almusaed A, Almssad A, Jaafar MK, Goodarzi M, Sahari KS. Effect of different building envelope materials on thermal comfort and air-conditioning energy savings: a case study in Basra city. Iraq J Energy Storage. 2020;5:101975.

Eshgarf H, Kalbasi R, Maleki A, Shadloo MS. A review on the properties, preparation, models and stability of hybrid nanofluids to optimize energy consumption. J Therm Anal Calorim. 2020;11:1–25.

Rostami S, Afrand M, Shahsavar A, Sheikholeslami M, Kalbasi R, Aghakhani S, Shadloo MS, Oztop HF. A review of melting and freezing processes of PCM/nano-PCM and their application in energy storage. Energy. 2020;15(211):118698.

Rad EA, Maddah S. Entropic optimization of the economizer’s pressure in a heat pump cycle integrated with a flash-tank and vapor-injection system. Int J Refrig. 2019;97:56–66. https://doi.org/10.1016/j.ijrefrig.2018.09.018.

Açıkkalp E, Ahmadi M. Performance evaluation of PEM fuel cell- chemical heat pump - absorption refrigerator hybrid system. Int J Ambient Energy. 2020. https://doi.org/10.1080/01430750.2020.1712238.

Shahid A, Huang HL, Khalique CM, Bhatti MM. Numerical analysis of activation energy on MHD nanofluid flow with exponential temperature-dependent viscosity past a porous plate. J Therm Anal Calorim. 2020;3:1–2.

Arain MB, Bhatti MM, Zeeshan A, Saeed T, Hobiny A. Analysis of arrhenius kinetics on multiphase flow between a pair of rotating circular plates. Math Probl Eng. 2020;1:2020.

Bhatti MM, Abdelsalam SI. Thermodynamic entropy of a magnetized Ree-Eyring particle-fluid motion with irreversibility process: a mathematical paradigm. ZAMM-J Appl Math Mech/Zeitschrift für Angewandte Mathematik und Mechanik. 2020;2:e202000186.

Ali Z, Zeeshan A, Bhatti MM, Hobiny A, Saeed T. Insight into the dynamics of Oldroyd-B fluid over an upper horizontal surface of a paraboloid of revolution subject to chemical reaction dependent on the first-order activation energy. Arab J Sci Eng. 2021;9:1.

Zhang L, Bhatti MM, Michaelides EE. Electro-magnetohydrodynamic flow and heat transfer of a third-grade fluid using a Darcy-Brinkman-Forchheimer model. Int J Num Methods Heat Fluid Flow. 2020. https://doi.org/10.1108/HFF-09-2020-0566.

Bhatti MM, Phali L, Khalique CM. Heat transfer effects on electro-magnetohydrodynamic Carreau fluid flow between two micro-parallel plates with Darcy–Brinkman–Forchheimer medium. Arch Appl Mech. 2021;7:1–3.

Bellos E, Tzivanidis C. Enhancing the performance of a CO2 refrigeration system with the use of an absorption chiller. Int J Refrig. 2019;1(108):37–52.

Purohit N, Gullo P, Dasgupta MS. Comparative assessment of low-GWP based refrigerating plants operating in hot climates. Energy Procedia. 2017;1(109):138–45.

Bellos E, Tzivanidis C. A comparative study of CO2 refrigeration systems. Energy Conv Manage: X. 2019;1(1):100002.

Gullo P. Innovative fully integrated transcritical R744 refrigeration systems for a HFC-free future of supermarkets in warm and hot climates. Int J Refrig. 2019;1(108):283–310.

Gullo P, Tsamos KM, Hafner A, Banasiak K, Yunting TG, Tassou SA. Crossing CO2 equator with the aid of multi-ejector concept: a comprehensive energy and environmental comparative study. Energy. 2018;1(164):236–63.

Fazelpour F, Morosuk T. Exergoeconomic analysis of carbon dioxide transcritical refrigeration machines. Int J Refrig. 2014;38:128–39. https://doi.org/10.1016/j.ijrefrig.2013.09.016.

Khanmohammadi S, Goodarzi M, Khanmohammadi S, Ganjehsarabi H. Thermoeconomic modeling and multi-objective evolutionary-based optimization of a modified transcritical CO2 refrigeration cycle. Therm Sci Eng Prog. 2018;5:86–96. https://doi.org/10.1016/j.tsep.2017.10.007.

Liu X, Liu C, Zhang Z, Chen L, Hou Y. Experimental study on the performance of water source trans-critical CO2 heat pump water heater. Energies. 2017. https://doi.org/10.3390/en10060810.

Song Y, Li D, Cao F, Wang X. Investigation of the optimal intermediate water temperature in a combined r134a and transcritical CO2 heat pump for space heating. Int J Refrig. 2017;79:10–24. https://doi.org/10.1016/j.ijrefrig.2017.04.018.

Yang D, Song Y, Cao F, Jin L, Wang X. Theoretical and experimental investigation of a combined R134a and transcritical CO2 heat pump for space heating. Int J Refrig. 2016;72:156–70. https://doi.org/10.1016/j.ijrefrig.2016.07.016.

Nguyen MQ, Shadloo MS, Hadjadj A, Lebon B, Peixinho J. Perturbation threshold and hysteresis associated with the transition to turbulence in sudden expansion pipe flow. Int J Heat Fluid Flow. 2019;1(76):187–96.

Song Y, Cao F. The evaluation of the optimal medium temperature in a space heating used transcritical air-source CO2 heat pump with an R134a subcooling device. Energy Convers Manag. 2018;166:409–23. https://doi.org/10.1016/j.enconman.2018.04.052.

Song Y, Cao F. The evaluation of optimal discharge pressure in a water-precooler-based transcritical CO2 heat pump system. Appl Therm Eng. 2018;131:8–18. https://doi.org/10.1016/j.applthermaleng.2017.11.092.

Joneydi Shariatzadeh O, Abolhassani SS, Rahmani M, Ziaee Nejad M. Comparison of transcritical CO2 refrigeration cycle with expander and throttling valve including/excluding internal heat exchanger: exergy and energy points of view. Appl Therm Eng. 2016;93:779–87. https://doi.org/10.1016/j.applthermaleng.2015.09.017.

Liu F, Groll EA, Ren J. Comprehensive experimental performance analyses of an ejector expansion transcritical CO2 system. Appl Therm Eng. 2016;98:1061–9. https://doi.org/10.1016/j.applthermaleng.2015.12.017.

Bai T, Yu J, Yan G. Advanced exergy analyses of an ejector expansion transcritical CO2 refrigeration system. Energy Convers Manag. 2016;126:850–61. https://doi.org/10.1016/j.enconman.2016.08.057.

Piquet A, Zebiri B, Hadjadj A, Shadloo MS. A parallel high-order compressible flows solver with domain decomposition method in the generalized curvilinear coordinates system. Int J Numer Methods Heat & Fluid Flow. 2019;30(1):2–38. https://doi.org/10.1108/HFF-01-2019-0048

Atyabi SA, Afshari E, Wongwises S, Yan WM, Hadjadj A, Shadloo MS. Effects of assembly pressure on PEM fuel cell performance by taking into accounts electrical and thermal contact resistances. Energy. 2019;15(179):490–501.

Ahmadi M, Mehrpooya M, Sameti M. Thermo-ecological analysis and optimization performance of an irreversible three-heat-source absorption heat pump. Energy Convers Manag. 2015;90:175–83. https://doi.org/10.1016/j.enconman.2014.11.021.

Ahmadi MH, Ahmadi MA, Bayat R, Ashouri M, Feidt M. Thermo-economic optimization of Stirling heat pump by using non-dominated sorting genetic algorithm. Energy Convers Manag. 2015;91:315–22. https://doi.org/10.1016/J.ENCONMAN.2014.12.006.

Shadloo MS, Rahmat A, Karimipour A, Wongwises S. Estimation of pressure drop of two-phase flow in horizontal long pipes using artificial neural networks. J Energy Resour Technol. 2020. https://doi.org/10.1115/1.4047593.

Ahmadi MH, Ahmadi M-A, Pourfayaz F, Bidi M. Thermodynamic analysis and optimization for an irreversible heat pump working on reversed Brayton cycle. Energy Convers Manag. 2016;110:260–7. https://doi.org/10.1016/J.ENCONMAN.2015.12.028.

Chahartaghi M, Kalami M, Ahmadi M, Kumar R, Jilte R. Energy and exergy analyses and thermo-economic optimization of geothermal heat pump for domestic water heating. Int J Low-Carbon Technol. 2019. https://doi.org/10.1093/ijlct/cty060.

Sarkar J, Bhattacharyya S, Gopal MR. Optimization of a transcritical CO2 heat pump cycle for simultaneous cooling and heating applications. Int J Refrig. 2004;27:830–8. https://doi.org/10.1016/j.ijrefrig.2004.03.006.

Ahmadi G, Toghraie D, Akbari O. Energy, exergy and environmental (3E) analysis of the existing CHP system in a petrochemical plant. Renew Sustain Energy Rev. 2019;1(99):234–42.

Deymi-Dashtebayaz M, Maddah S, Fallahi E. Thermo-economic-environmental optimization of injection mass flow rate in the two-stage compression refrigeration cycle Case study: mobarakeh steel company in Isfahan. Iran Int J Refrig. 2019;106:7–17. https://doi.org/10.1016/j.ijrefrig.2019.06.020.

Toghyani S, Afshari E, Baniasadi E, Shadloo MS. Energy and exergy analyses of a nanofluid based solar cooling and hydrogen production combined system. Renew Energy. 2016;102:904–21. https://doi.org/10.1016/j.applthermaleng.2016.03.178.

Akbulut U, Utlu Z, Kincay O. Exergy, exergoenvironmental and exergoeconomic evaluation of a heat pump-integrated wall heating system. Energy. 2016;107:502–22.

Maddah S, Goodarzi M, Safaei MR. Comparative study of the performance of air and geothermal sources of heat pumps cycle operating with various refrigerants and vapor injection. Alexandria Eng J. 2020;59:4037–47. https://doi.org/10.1016/j.aej.2020.07.009.

Richter MR, Song SM, Yin JM, Kim MH, Bullard CW, Hrnjak PS. Experimental results of transcritical CO2 heat pump for residential application. Energy. 2003;28:1005–19. https://doi.org/10.1016/S0360-5442(03)00065-3.

Maddah S, Deymi-Dashtebayaz M, Maddah O. 4E analysis of thermal recovery potential of industrial wastewater in heat pumps: an invisible energy resource from the iranian casting industry sector. J Clean Prod. 2020;265:121824. https://doi.org/10.1016/j.jclepro.2020.121824.

Deymi-Dashtebayaz M, Maddah S, Goodarzi M, Maddah O. Investigation of the effect of using various HFC refrigerants in geothermal heat pump with residential heating applications. J Therm Anal Calorim. 2020;141:361–72. https://doi.org/10.1007/s10973-020-09539-5.

Liao SM, Zhao TS, Jakobsen A. A correlation of optimal heat rejection pressures in transcritical carbon dioxide cycles. Appl Therm Eng. 2000;20:831–41. https://doi.org/10.1016/S1359-4311(99)00070-8.

Chen Y, Gu J. The optimum high pressure for CO2 transcritical refrigeration systems with internal heat exchangers. Int J Refrig. 2005;28:1238–49. https://doi.org/10.1016/j.ijrefrig.2005.08.009.

Qi PC, He YL, Wang XL, Meng XZ. Experimental investigation of the optimal heat rejection pressure for a transcritical CO2 heat pump water heater. Appl Therm Eng. 2013;56:120–5. https://doi.org/10.1016/j.applthermaleng.2013.03.045.

Kim SC, Won JP, Kim MS. Effects of operating parameters on the performance of a CO2 air conditioning system for vehicles. Appl Therm Eng. 2009;29:2408–16. https://doi.org/10.1016/j.applthermaleng.2008.12.017.

Kauf F. Determination of the optimum high pressure for transcritical CO2-refrigeration cycles. Int J Therm Sci. 1999;38:325–30. https://doi.org/10.1016/S1290-0729(99)80098-2.

Okasha A, Müller N. Simulation and performance correlation for transcritical CO2 heat pump cycle, international refrigeration and air conditioning conference, 2018: Paper 2056. https://docs.lib.purdue.edu/iracc/2056.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maddah, S., Safaei, M.R. Determination of the optimal discharge pressure of the transcritical CO2 heat pump cycles for heating and cooling performances based on new correlation. J Therm Anal Calorim 145, 1537–1546 (2021). https://doi.org/10.1007/s10973-021-10723-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10723-4