Abstract

A comparative study of vacuum versus ambient pressure inert gas thermogravimetry was performed on silver carboxylates compounds. Some of the complexes from this group have been previously successfully applied as precursors for both chemical vapour deposition and electron beam-induced deposition. Considerable differences were found between the thermogravimetry methods, which we associate with changes in evaporation dynamics. Vacuum thermogravimetry sublimation onsets consistently occurred at lower temperatures than ambient pressure N2-flow thermogravimetry, where the differences reached up to 120 °C. Furthermore, compound sublimation during N2-TGA was suppressed to such an extent that significant thermal decomposition of the compounds into metal and volatile organic fragments was observed while at vacuum the same complexes sublimed as intact molecules. Moreover, thermal stability of silver complexes was investigated using isothermal thermogravimetry. These findings are interesting for the field of thin film synthesis and nanomanufacturing via chemical vapour deposition, atomic layer deposition and focused electron beam induced deposition. In all three methods, delivery of functional precursor over the substrate is crucial. The presented results prove that vacuum thermogravimetry can be used as fast method of pre-screening for novel, especially low-volatility precursors.

Graphic abstract

Similar content being viewed by others

Introduction

Thermogravimetry (TGA) is an analytical method, which allows to investigate heat-induced mass changes [1]. Depending on the atmosphere, it can be used to study different heat-related phenomena, such as evaporation, drying, sorption of gases [2], thermal decomposition [3, 4] (with formation of volatile species), oxidation [5] and/or oxidative decomposition, as well as certain thermally induced chemical reactions [6, 7]. In some cases, vacuum is used, especially when analysing oxygen-sensitive species [8], e.g. fuels [9]. In-vacuum TGA measurements have also been applied to study early stages of metal oxidation in low-pressure corrosive atmospheres [10].

Depending on the heating strategy, TGA experiments can be divided into two main groups: dynamic, where the sample is heated at a constant rate, and isothermal, where the temperature is constant. It is also possible to program nonlinear temperature changes, e.g. when the heating rate is controlled by the sample’s temperature [1].

TGA is frequently used to examine the thermal stability, decomposition temperature, evaporation process and vapour pressure of potential chemical vapour deposition (CVD) precursors [11,12,13,14]. TGA (especially when paired with differential scanning calorimetry) allows to determine both the initiation of evaporation and thermal decomposition temperatures of the measured compound. Additionally, it enables determining if the decomposition occurs in one or multiple steps, which is important from the purity viewpoint of the deposited film, particularly when using metalorganic precursors [12] (so-called MO-CVD).

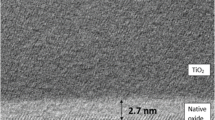

Besides CVD, metalorganic compounds have found applications as precursors for focused electron beam induced deposition (FEBID), a direct and maskless method of manufacturing structures at the nanometre scale. Gaseous precursor molecules are introduced onto the surface of the substrate through a gas injection system (GIS) inside a scanning electron microscope’s (SEM) vacuum chamber. There, the applied focused electron beam locally dissociates the precursor, ideally leaving a pure metal deposit. The detached organic ligands desorb and are pumped out of the chamber [15].

In reality, the purity of the deposit is frequently compromised, mostly due to two unwanted processes, which may occur on the substrate during electron irradiation of adsorbed species, i.e. the co-deposition of ligands and/or incomplete dissociation of precursor molecules. Co-deposition of material from residual hydrocarbon gases is also a process deteriorating deposit purity, but supply of the functional precursor is typically chosen orders of magnitude larger than the residual gases to avoid this. Mentioned processes limit possible applications of produced nanostructures [15,16,17]. For example, high purity is essential when producing components for plasmonic nanodevices, as usually a metallic character is required [18,19,20].

To increase the purity, a novel class of a potential FEBID precursor has been proposed: silver carboxylates. Compounds from this family have already been tested as potential CVD precursors [21,22,23]. Two of them: [Ag2(µ-O2CC(Me2)Et)2] and [Ag2(µ-O2CC2F5)2] have already been used in FEBID to deposit structures with purity exceeding 70 at%. Despite having been successfully used during deposition, both [Ag2(µ-O2CC(Me2)Et)2] [24] and [Ag2(µ-O2CC2F5)2] [25, 26] have exhibited low volatility (compared to commercial FEBID compounds) and had to be heated up to 150 °C and 160–180 °C, respectively, to maintain sufficient molecular flux. As the heating occurs within the precursor reservoir, the compound is at risk of thermal decomposition before it reaches the substrate. TGA can be used as a form of pre-screening of potential precursors (same as for CVD) and could allow for determining compound thermal stability and estimating the optimal GIS temperature window prior to deposition. However, looking closer at the TGA results for fluorinated silver carboxylate [Ag2(µ-O2CC2F5)2], we can see significant discrepancies between the evaporation temperatures given by TGA and the temperatures used in the FEBID process. During FEBID, the compound was sublimed at temperatures approx. 150 °C lower than initial evaporation temperatures derived from TGA [23,24,25, 27]. Such discrepancies limit the applicability of non-vacuum TGA as a pre-screening method for FEBID.

In this work, we propose using in-vacuum thermogravimetry (VTGA) in place of inert gas flow TGA, a method, as aforementioned applied for investigation of fuels, but only rarely used for organometallic compounds [30]. By using low vacuum, mass loss curves were obtained for each investigated compound, where their evaporation temperatures correspond considerably better to the temperatures used during FEBID. Furthermore, the precursors’ thermal stability was tested by applying isothermal heating for a few hours, imitating FEBID experimental conditions. The method was tested on several potential silver precursors from the carboxylate family, whose structural formulas are presented in Fig. 1.

Experimental

Precursor synthesis

Silver precursors were synthesised according to previously reported procedures [29, 31]. In the case of non-fluorinated silver carboxylates, an aqueous AgNO3 solution was added dropwise to the aqueous solution of the sodium salt (obtained by neutralising the acid with a stoichiometric amount of sodium base). A white, amorphous solid was immediately obtained.

Perfluorinated silver carboxylates were synthesised through the reaction of fluorinated carboxylic acid and silver carbonate in a water–ethanol environment. After solvent evaporation, a white solid formed.

Thermogravimetry equipment

VTGA experiments were carried out using Netzsch TG209 F1 Libra TGA equipment, connected to Agilent Technologies SH110 dry scroll pump, providing a minimum pressure of 6.6 × 10−2 mbar. The precision of the mass readout was 0.0001 mg. The sublimation experiments were performed in Al2O3 crucibles to avoid crucible/compound sample chemical reactions. The thermal contact between the furnace and crucible is reduced compared to standard TGA, due to the lack of proper atmosphere. Therefore, the temperature was measured and the heating process was controlled using the sample’s (crucible’s) thermocouple. Proportional, integral, derivative (PID) controller's parameters were optimised to avoid signal oscillations caused by temperature feedback looping. However, the PID parameter settings were not ideal for the end of the main mass loss event and resulted in a small local minimum. This minimum is most probably only a measurement artefact and has no actual physical meaning. No inert gas flow was applied during process. Each TGA curve was corrected for signal overshooting using an empty crucible measurement curve. The heating rate selected for these tests was 5 K min−1. The initial compound sample masses ranged between 9 and 20 mg. Ambient pressure gas flow TGA experiments were performed using Netzsch STA 449 F3 Jupiter, with an applied heating rate of 5 K min−1 and a N2 gas flow of 40 mL min−1, to avoid reactions between the compound and atmospheric gases. Initial compound sample masses ranged from 15 to 16 mg.

Results and discussion

VTGA measurements were taken on different silver organometallic complexes: [Ag2(µ-O2CC(Me2)Et)2], [Ag2(µ-O2CC2F5)2], already successfully applied as FEBID silver precursors, providing high purity deposits [24, 25], and three other fluorinated and non-fluorinated silver carboxylates: [Ag2(µ-O2CCF3)2], [Ag2(µ-O2CC3F7)2], [Ag2(µ-O2tBu)2]. The collected results are presented in Fig. 2. We can observe that both non-fluorinated carboxylates decompose partially, leaving non-volatile species within the crucible at 45.0 ± 2% and 49 ± 1% of the initial masses of [Ag2(µ-O2CC(Me2)Et)2] and [Ag2(µ-O2CtBu)2], respectively. The measurement error was deduced from the slight mass increase after the local minimum (and main mass loss event) and amounted to 1.0% for [Ag2(µ-O2CC(Me2)Et)2 and 2.0% for [Ag2(µ-O2CtBu)2]. The mass reading error of the TGA equipment is negligible as it allows recording of mass changes with precision down to 0.0001 mg, which is five orders of magnitude lower than masses of measured compounds (9–20 mg). The Ag contents in the pristine compounds are 48.4 mass% for [Ag2(µ-O2CC(Me2)Et)2] and 51.7 mass% for [Ag2(µ-O2CtBu)2]. The differences to the measured mass residuals are 3.4 ± 2 mass% and 1.7 ± 1 mass%, respectively, and points to sublimation of a small amount of intact precursor molecules during the temperature ramp. If sublimation occurred in a small temperature window before or simultaneously with thermal decomposition would be the subject of follow-up isothermal TGA measurements. A further observation is that both non-fluorinated silver complexes exhibited initial mass losses at lower temperatures than fluorinated silver carboxylates.

In contrast, all fluorinated compounds left much less residue in the crucibles: approx. 8.0% for [Ag2(µ-O2CCF3)2], 5.0% for [Ag2(µ-O2CC2F5)2] and 4.0% for [Ag2(µ-O2CC3F7)2] with estimated errors smaller than ± 1% (estimated the same way as above for non-fluorinated silver complexes). These values are considerably lower than the Ag molar mass contents of each complex (48.9%, 39.9% and 33.6%, respectively), proving that silver carriers are present within the gas phase. Silver containing vapour species were also observed previously, using variable temperature infrared spectrometry on the vapours of [Ag2(µ-O2CC2F5)2] and [Ag2(µ-O2CC3F7)2] [27]. The results indicate that not only [Ag2(µ-O2CC2F5)2], but also other fluorinated carboxylates could be potentially used as precursors for the deposition of silver via FEBID. When comparing the mass loss curves of all three fluorinated carboxylates, it can be seen that [Ag2(µ-O2CC2F5)2] exhibits the lowest sublimation temperature, so higher GIS temperatures will be needed for [Ag2(µ-O2CCF3)2] and [Ag2(µ-O2CC3F7)2] to achieve comparable molecule fluxes as for [Ag2(µ-O2CC2F5)2]. This VTGA information is very important in designing the experimental FEBID procedure.

In-vacuum versus ambient pressure N 2 flow TGA for selected silver carboxylates

To investigate the influence of low vacuum on the TGA results, [Ag2(µ-O2CC2F5)2], [Ag2(µ-O2CCF3)2] and [Ag2(µ-O2CC(Me2)Et)2] were examined using both VTGA and ambient pressure N2-flow TGA. The results are shown in Fig. 3a–c. As outlined in the previous section the error of the mass per cent values reported below are smaller ± 1 mass%.

Firstly, when comparing these methods for [Ag2(µ-O2CC2F5)2], it is visible that at lower pressure, sublimation begins at lower temperatures. During VTGA, the compound was fully sublimated from 250 °C onwards, whereas under ambient pressure N2 flow TGA, the mass loss stopped at approx. 370 °C. Secondly, under vacuum only 5.0% of the initial mass remained in the crucible. For ambient pressure N2 flow TGA, the amount of remnants reached approx. 37.0% of initial mass. Silver accounts for 39.8% of the molar mass of this complex.

This compound has been used as FEBID precursor in other studies and is known to produce high purity deposits of Ag 76.0 at%. In reported cases, the gas injection system reached temperatures up to 180 °C [25, 26]. It can be seen that the results from FEBID support those from VTGA. Attaining high purity silver deposits is only possible when silver-containing species are present within the gas phase.

Similar results were obtained for another fluorinated silver carboxylate, [Ag2(µ-O2CCF3)2] (Fig. 3b). At low vacuum, this precursor starts sublimating at lower temperatures than at atmospheric pressure and leaves significantly less residues in the crucible (8.0% in vacuum vs. 54.0% atmospheric pressure, N2 flow).

A different behaviour was observed for non-fluorinated [Ag2(µ-O2CC(Me2)Et)2] (Fig. 3c). Under both vacuum and ambient pressure N2 flow conditions, the compound left approx. 45.0% and 49.0%, respectively, of its initial mass in the crucible. The expected leftover mass for silver from thermal decomposition was 48.4% (the mass percentage of Ag in compound's molar mass), which is in line with the observed leftover mass for the ambient pressure experiment. However, the remaining mass obtained from VTGA was lower, indicating that thermal decomposition and evaporation occur concurrently.

Next, compounds [Ag2(µ-O2CC2F5)2] and [Ag2(µ-O2CCF3)2] were kept for 8 h at 180 °C (highest GIS temperature used for deposition of the first one) to determine their stability during long time isothermal heating (imitating FEBID conditions). The results are presented in Fig. 3d. On the one hand, [Ag2(µ-O2CC2F5)2] fully sublimed within the first 100 min of the experiment, leaving only 2.0% of its initial mass in the crucible. We can attribute this value of remnants to possible impurities (e.g. silver coming from photodecomposition), which may be present in the compound or to the slight thermal decomposition of the precursor. On the other hand, [Ag2(µ-O2CCF3)2] sublimed at a much lower rate, stabilising at around 9.0% of mass loss after 450 min. Similarly to [Ag2(µ-O2CC2F5)2], the mass residues can be attributed to possible impurities; however, they are significantly higher than in the previous case, and therefore, we cannot exclude the possibility of thermal decomposition occurring alongside sublimation. Nevertheless, both compounds have proven to be rather stable during long time heating at low vacuum, which is an important aspect for FEBID experiments. As the initial masses of the compounds were different, we can only compare the relative mass losses versus time. However, it can be observed that the rate of sublimation for [Ag2(µ-O2CC2F5)2] is faster and that this compound will give higher molecular fluxes due to GIS heating, which is important from the viewpoint of deposition growth rate during FEBID.

To simplify comparing ambient pressure N2 flow and VTGA measurements, the results are summarised in Table 1, for mass losses of 10.0% and end of mass loss. One can clearly see that non-fluorinated compound decomposition and sublimation occurs at lower temperatures, both in-vacuum and at ambient pressure. For both TGA methods, decomposition plays a significant role, as relatively high percentages of residues were obtained in the crucible after the mass loss process ended. Nevertheless, for all measured carboxylates, the mass loss starts at lower temperatures during VTGA. For fluorinated compounds, the temperatures at which mass loss reached 10.0% were approx. 90–120 °C lower than during gas flow experiments. For [Ag2(µ-O2CC(Me2)Et)2], the difference was around 40 °C. Furthermore, for all measured complexes, mass loss stops at lower temperatures under vacuum conditions than at ambient pressure N2-flow.

Discussion

The difference in initial sublimation temperature between in-vacuum and N2-gas flow TGA can be explained by different pressure levels during both experiments. VTGA was performed with a background pressure level of 10−1–10−2 mbar, which is 4–5 orders of magnitude lower than 1 bar of atmospheric pressure used for N2-flow TGA. The sublimation process in the system containing the compound in solid and gas phase is driven by the chemical potentials of both phases. The chemical potential generally rises with pressure and temperature with different rates for gases and solid materials. As the chemical potential of a gas generally increases more than the chemical potential of a solid [32], more energy is needed to sublimate the precursor, i.e. for ambient pressure (N2 flow TGA) we need to increase the temperature to sublimate the same amount of the substance as for VTGA. This explains why the same level of mass loss during ambient pressure N2 flow TGA was observed at lower temperatures using VTGA. Of note is that the vapour pressure of a measured gas increases slightly with increasing pressure of inert gas. However, this effect is small. For example, for water at 25 °C the vapour pressure would increase by 0.074% when adding 1 atm. of inert gas [32]. Furthermore, the N2-flow and VTGA experiments are not performed in closed systems and not at thermal equilibrium (temperature continuously changes). Considering this, even though vapour pressure is frequently used as a measure of volatility of a compound, this concept does not correctly apply here. Evaporation at low temperatures is industrially used as vacuum distillation in the oil refinery industry [33] or in at laboratory scale for purification of organometallic compounds during synthesis [34, 35]. However, for precursors used in chemical vapour deposition, atomic layer deposition, and FEBID vacuum TGA curves are generally not at hand although they would be of great help to design the deposition process with respect to precursor reservoir temperatures, carrier gas pressures, substrate temperature and reproducibility of the deposition rate.

The difference in the amount of mass left in the crucible for fluorinated complexes can be explained by the at least partial thermal decomposition of these compounds during TGA measurements, especially at ambient pressure with N2 flow. For all compounds, silver is the heaviest element. Considering the fluorinated complexes measured with both methods, silver mass corresponds to around 39.8% of the molar mass of [Ag2(µ-O2CC2F5)2] and 48.9% of the molar mass of [Ag2(µ-O2CCF3)2]. The mass left in the crucible during ambient pressure N2 flow TGA was on the level of 37.0% for the first and 54.0% of the latter compound. This indicates that the precursor partially thermally decomposes, also in vacuum experiments, leaving silver-containing species in the crucible. The presence of metallic silver, along with some organic impurities, (result of thermal decomposition), has also been reported in previously published ambient pressure N2 flow thermal analysis of [Ag2(µ-O2CC2F5)2] [27]. In the case of VTGA, where the mass remnants are much lower (5.0% for [Ag2(µ-O2CC2F5)2] and 8.0% [Ag2(µ-O2CCF3)2]) there is probably only very limited thermal decomposition and mostly intact molecules of the precursors are present in the gas phase.

[Ag2(µ-O2CC(Me2)Et)2] thermally decomposed during both VTGA and N2-flow measurements. The mass percentage of silver in the precursor molecule [Ag2(µ-O2CC(Me2)Et)2] amounts to 48.4%. The ambient pressure N2 gas flow TGA showed 49.0% of mass remaining after the measurement, which hints that mostly silver, as the heaviest element, stayed in the crucible. Literature sources also indicate thermal decomposition of the precursor to metallic silver at temperatures between 195 and 250 ℃ [23]. The remaining mass present after VTGA was slightly lower, reaching 45.0% of initial mass, which indicates the sublimation of at least some part of silver-containing species. The exact amount is hard to estimate, as we do not know the exact pathway of thermal decomposition occurring in the crucible. Interestingly, this compound has been used as a silver FEBID precursor and has been reported to give high purity deposits, i.e. approx. 74.0 at% of Ag [24]. This means that at high vacuum there must be silver containing species within gas phase. As volatile silver-containing ions were detected using the electron ionisation mass spectrometry (EI MS) technique in high vacuum [29], we can assume that lowering background pressure would facilitate sublimation over decomposition.

Summarising, we can state that thermal decomposition and sublimation are two competing processes that occur during heating of the silver carboxylates. By using low vacuum, we decrease the work necessary for the molecule to overcome the ambient pressure and join the gas phase, making sublimation the more energetically preferable process. That is the reason why for VTGA intact molecules can sublimate at temperatures lower than the thermal decomposition threshold, leaving less mass in the crucible. Quantification of sublimation and decomposition rates will be subject of follow-up studies.

Stable low-temperature sublimation would explain the feasibility of FEBID with silver carboxylates as FEBID is usually performed in high vacuum. With background pressures 2–3 orders of magnitude lower than used in VTGA, the sublimation could start at even lower temperatures, allowing for more silver-containing species to sublimate and reach the substrate surface. There, it can be locally decomposed to high silver content material by the focused electron beam. As was previously mentioned, intact precursor molecules of [Ag2(µ-O2CC(Me2)Et)2] were detected within gas phase in high vacuum with EI MS [29], with similar results for [Ag2(µ-O2CCF3)2] [36].

Conclusions

VTGA was applied to measure mass loss during heating of known and potential CVD and FEBID silver carboxylate precursors. In all presented cases, under low vacuum the compounds sublimed at lower temperatures, leaving less remnants in the crucible than during N2-gas flow measurements. By lowering the ambient pressure during TGA, it was possible to create thermodynamic conditions facilitating the sublimation of more molecules at temperatures below the thermal decomposition threshold. The sublimation temperatures determined using VTGA stand in better agreement with the temperature ranges used during FEBID than those obtained by means of ambient pressure N2-gas flow TGA.

Based on compound thermal stability analysis, it was determined that the fluorinated carboxylates are more promising as silver FEBID precursors. However, as shown for [Ag2(µ-O2CC(Me2)Et)2], it may still be possible to deposit silver when using non-perfluorinated precursors. In this sense, the VTGA technique proved to be an attractive method for confirming the suitability of precursors for FEBID. The temperature window for the sublimation of low volatility precursors was determined using the ramping temperature mode. The isothermal mode was used to check the thermal stability and sublimation rate at a given temperature for two compounds [Ag2(µ-O2CCF3)2] and [Ag2(µ-O2CC2F5)2].

We found evidence that the lower temperature onset for sublimation (mass change) favours the entire sublimation of certain carboxylates during the TGA programmed temperature rise before the temperature of thermal decomposition is reached. Further details of the temperature-dependent competition of sublimation and decomposition processes could be obtained by extended isothermal TGA investigations and FTIR or mass spectrometric studies performed in situ during temperature ramp TGA. We hope to initiate these kind of measurements in the field of thermal investigations with our present manuscript.

References

Bottom R. Thermogravimetric analysis. In: Gabbott P, editor. Principles and applications of thermal analysis. London: Blackwell; 2008. p. 87–118.

Guo Y, Zhang H, Liu Y. Desorption characteristics and kinetic parameters determination of molecular sieve by thermogravimetric analysis/differential thermogravimetric analysis technique. Adsorpt Sci Technol. 2018;36(7–8):1389–404.

Conesa JA, Marcilla A, Font R, Caballero JA. Thermogravimetric studies on the thermal decomposition of polyethylene. J Anal Appl Pyrolysis. 1996;36(1):1–15.

Gai C, Zhang Y, Chen W-T, Zhang P, Dong Y. Thermogravimetric and kinetic analysis of thermal decomposition characteristics of low-lipid microalgae. Bioresour Technol. 2013;150:139–48.

Coker EN, The oxidation of aluminum at high temperature studied by thermogravimetric analysis and differential scanning calorimetry. Sandia National Laboratories (US); 2013. (SAND2013–8424).

Zaki MI, Hasan MA, Pasupulety L, Kumari K. Thermochemistry of manganese oxides in reactive gas atmospheres: probing catalytic MnOx compositions in the atmosphere of CO + O2. Thermochim Acta. 1998;311(1):97–103.

Rao CJ, Ningshen S, Mallika C, Mudali UK. Molten salt corrosion behavior of structural materials in LiCl-KCl-UCl3 by thermogravimetric study. J Nucl Mater. 2018;501:189–99.

Ashby EC, Claudy P, Bousquet J, Etienne J. High vacuum DTA-TGA instrumentation for air-sensitive compounds. J Chem Educ. 1975;52(9):618.

Zhou G, Roby S, Wei T, Yee N. Fuel heat of vaporization values measured with vacuum thermogravimetric analysis method. Energy Fuels. 2014;28(5):3138–42.

Auinger M, Vogel A, Vogel D, Rohwerder M. Early stages of oxidation observed by in situ thermogravimetry in low pressure atmospheres. Corros Sci. 2014;86:183–8.

Du L, Chu W, Miao H, Xu C, Ding Y. Synthesis, characterization, thermal properties of silicon(iv) compounds containing guanidinato ligands and their potential as CVD precursors. RSC Adv. 2015;5(88):71637–43.

Kunte GV, Shivashankar SA, Umarji AM. Thermogravimetric evaluation of the suitability of precursors for MOCVD. Meas Sci Technol. 2018;19(2):025704.

Jakob A, Schmidt H, Djiele P, Shen Y, Lang H. Phosphane/phosphite silver(I) carboxylates as CVD precursors. Microchim Acta. 2006;156(1):77–81.

Siddiqi MA, Atakan B. Combined experiments to measure low sublimation pressures and diffusion coefficients of organometallic compounds. Thermochim Acta. 2007;452(2):128–34.

Huth M, Porrati F, Dobrovolskiy OV. Focused electron beam induced deposition meets materials science. Microelectronic Eng. 2018;185–186:9–28.

Botman A, Mulders JJL, Hagen CW. Creating pure nanostructures from electron-beam-induced deposition using purification techniques: a technology perspective. Nanotechnology. 2009;20(37):372001.

Huth M, Porrati F, Schwalb C, Winhold M, Sachser R, Dukic M, Adams J, Fantner G. Focused electron beam induced deposition: a perspective. Beilstein J Nanotech. 2012;3:597–619.

Ozbay E. Plasmonics: merging photonics and electronics at nanoscale dimensions. Science. 2006;311(5758):189.

Höflich K, Yang RB, Berger A, Leuchs G, Christiansen S. The direct writing of plasmonic gold nanostructures by electron-beam-induced deposition. Adv Mater. 2011;23(22–23):2657–61.

Winkler R, Schmidt F-P, Haselmann U, Fowlkes JD, Lewis BB, Kothleitner G, Rack PD, Plank H. Direct-write 3D Nanoprinting Of Plasmonic Structures. ACS Appl Mater Interfaces. 2017;9(9):8233–40.

Szłyk E, Piszczek P, Grodzicki A, Chaberski M, Goliński A, Szatkowski J, Błaszczyk T. CVD of AgI complexes with tertiary phosphines and perfluorinated carboxylates—a new class of silver precursors. Chem Vap Depos. 2001;7(3):111–6.

Panneerselvam A, Malik MA, O’Brien P, Helliwell M. The aerosol-assisted CVD of silver films from single-source precursors. Chem Vap Depos. 2009;15(1–3):57–63.

Szczęsny R, Szłyk E. Thermal decomposition of some silver(I) carboxylates under nitrogen atmosphere. J ThermAnal Calorim. 2013;111(2):1325–30.

Höflich K, Jurczyk J, Zhang Y, Puydinger dos Santos MV, Götz M, Guerra-Nuñez C, Best JP, Kapusta C, Utke I. Direct electron beam writing of silver-based nanostructures. ACS Appl Mater Interfaces. 2017;9(28):24071–24077.

Berger L, Madajska K, Szymanska IB K. Höflich, Polyakov MN, Jurczyk J, Guerra-Nuñez C, Utke I. Gas-assisted silver deposition with a focused electron beam. Beilstein J Nanotech. 2018;9:224–232.

Höflich K, Jurczyk JM, Madajska K, Götz M, Berger L, Guerra-Nuñez C, Haverkamp C, Szymanska I, Utke I. Towards the third dimension in direct electron beam writing of silver. Beilstein J Nanotech. 2018;9:842–9.

Szłyk E, Piszczek P, Chaberski M, Goliński A. Studies of thermal decomposition process of Ag(I) perfluorinated carboxylates with temperature variable IR and MS. Polyhedron. 2001;20(22):2853–61.

Kuzmina N, Paramonov S, Ivanov R, Kezko V, Polamo K, Troyanov S. Silver pivalate as a new volatile precursor for thin film deposition. J Phys IV France. 1999;09(PR8):923–8.

Szymańska I, Piszczek P, Szczęsny R, Szłyk E. Thermal and MS studies of silver(I) 2,2-dimethylbutyrate complexes with tertiary phosphines and their application for CVD of silver films. Polyhedron. 2007;26(12):2440–8.

Park K-H, Marshall WJ. Remarkably volatile copper(II) complexes of N,N′-unsymmetrically substituted 1,3-diketimines as precursors for Cu metal deposition via CVD or ALD. J Am Chem Soc. 2005;127(26):9330–1.

Szłyk E, Łakomska I, Grodzicki A. Thermal and spectroscopic studies of the Ag(I) salts with fluorinated carboxylic and sulfonic acid residues. Thermochim Acta. 1993;223:207–12.

Kaufman M. Principles of thermodynamics. Boca Raton: CRC Press; 2002.

Stauffer E, Dolan JA, Newman R. Flammable and combustible liquids. In: Stauffer E, Dolan JA, Newman R, editors. Fire debris analysis. Burlington: Academic Press; 2008. p. 199–233.

Zharkova GI, Sysoev SV, Turgambaeva AE, Igumenov IK. Thermal behavior of a series of monomeric Ni(II) complexes with β-iminoketones. Thermochim Acta. 2013;560:7–11.

Lim BS, Rahtu A, Park J-S, Gordon RG. Synthesis and characterization of volatile, thermally stable, reactive transition metal amidinates. Inorg Chem. 2003;42(24):7951–8.

Adams SK, Edwards DA, Richards R. Silver(I) carboxylates. I. Mass spectra and low frequency infrared spectra. Inorg Chim Acta 1975;12(1):163–166.

Acknowledgements

We thank the NAFUMA group (University of Oslo) for providing the vacuum TGA equipment.

Funding

Open Access funding provided by Lib4RI – Library for the Research Institutes within the ETH Domain: Eawag, Empa, PSI & WSL. The research was conducted with the financial support of EU Horizon 2020 Marie Curie-Sklodowska Innovative Training Network “ELENA”, Grant Agreement No. 722149.

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jurczyk, J., Glessi, C., Madajska, K. et al. Vacuum versus ambient pressure inert gas thermogravimetry: a study of silver carboxylates. J Therm Anal Calorim 147, 2187–2195 (2022). https://doi.org/10.1007/s10973-021-10616-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10616-6