Abstract

A novel epoxy composite with flame retardance and fire resistance was prepared by adding silicate glass frit (SGF) and ammonium polyphosphate (APP) into the epoxy resin. In the combustion test, epoxy composites displayed obvious flame retardance feature, showing much lower heat release rate, total heat release and total smoke production than epoxy resin. The composite residue formed at 900 °C had a flexural strength of 19.05 MPa. In addition, possible mechanisms for the phase separation and crystallization reactions at high temperatures were also investigated in detail through thermogravimetric analyzer, X-ray diffraction, X-ray photoelectron spectrometer, and scanning electron microscopy. It was suggested that phosphorus element tends to migrate to the surface of the composite residue during firing process, and sodium element from SGF is selectively combined with the phosphorus element to obtain crystalline phases. With this unique phase separation and crystallization reactions, the fire resistance of the epoxy composite was significantly improved.

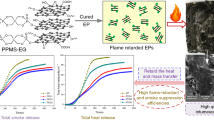

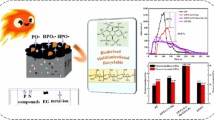

Graphical abstract

Similar content being viewed by others

References

Xu MJ, Zhao W, Li B. Synthesis of a novel curing agent containing organophosphorus and its application in flame-retarded epoxy resins. J Appl Polym Sci. 2014;131:1–12. https://doi.org/10.1002/app.41159.

Gu JW, Liang C, Zhao X, et al. Highly thermally conductive flame-retardant epoxy nanocomposites with reduced ignitability and excellent electrical conductivities. Compos Sci Technol. 2017;139:83–9. https://doi.org/10.1016/j.compscitech.2016.12.015.

Wang N, Teng HW, Li L, Zhang J, Kang P. Synthesis of phosphated K-carrageenan and its application for flame-retardant waterborne epoxy. Polymers. 2018;10:1268. https://doi.org/10.3390/polym10111268.

Chen ZK, Yang G, Yang JP, Fu SY, Ye L, Huang YG. Simultaneously increasing cryogenic strength, ductility and impact resistance of epoxy resins modified by n-butyl glycidyl ether. Polymer. 2009;50:1316–23. https://doi.org/10.1016/j.polymer.2008.12.048.

Zhang JH, Kong QH, Wang DY. Simultaneously improving the fire safety and mechanical properties of epoxy resin with Fe-CNTs via large-scale preparation. J Mater Chem A. 2018;6:6376. https://doi.org/10.1039/c7ta10961j.

Guan FL, Gui CK, Zhang HB, Jiang ZG, Jiang Y, Yu ZZ. Enhanced thermal conductivity and satisfactory flame retardancy of epoxy/alumina composites by combination with graphene nanoplatelets and magnesium hydroxide. Compos Part B. 2016;98:134–40. https://doi.org/10.1016/j.compositesb.2016.04.062.

Müller P, Morys M, Sut A, Jäger C, Illerhaus B, Schartel B. Melamine poly(zinc phosphate) as flame retardant in epoxy resin: decomposition pathways, molecular mechanisms and morphology of fire residues. Polym Degrad Stabil. 2016;130:307–19. https://doi.org/10.1016/j.polymdegradstab.2016.06.023.

Lu SY, Hamerton I. Recent developments in the chemistry of halogen-free flame retardant polymers. Prog Polym Sci. 2002;27:1661–712. https://doi.org/10.1016/s0079-6700(02)00018-7.

Wang ZH, Wei P, Qian Y, Liu JP. The synthesis of a novel graphene-based inorganic–organic hybrid flame retardant and its application in epoxy resin. Compos Part B. 2014;60:341–9. https://doi.org/10.1016/j.compositesb.2013.12.033.

Guo WW, Yu B, Yuan Y, Song L, Hu Y. In situ preparation of reduced graphene oxide/DOPO-based phosphonamidate hybrids towards high-performance epoxy nanocomposites. Compos Part B. 2017;123:154–64. https://doi.org/10.1016/j.compositesb.2017.05.024.

Gu JW, Dang J, Wu YL, Xie C, Han Y. Flame-retardant, thermal, mechanical and dielectric properties of structural non-halogenated epoxy resin composites. Polym Plast Technol. 2012;51:1198–203. https://doi.org/10.1080/03602559.2012.694951.

Mansouri J, Burford RP, Cheng YB, Hanu L. Formation of strong ceramified ash from silicone-based compositions. J Mater Sci. 2005;40:5741–9. https://doi.org/10.1007/s10853-005-1427-8.

Hanu LG, Simon GP, Mansouri J, Burford RP, Cheng YB. Development of polymer–ceramic composites for improved fire resistance. J Mater Process Tech. 2004;153:401–7. https://doi.org/10.1016/j.jmatprotec.2004.04.104.

Li YM, Deng C, Wang YZ. A novel high-temperature-resistant polymeric material for cables and insulated wires via the ceramization of mica-based ceramifiable EVA composites. Compos Sci Technol. 2016;132:116–22. https://doi.org/10.1016/j.compscitech.2016.07.007.

Anyszka R, Bielinski DM, Pedzich Z, Szumera M. Influence of surface-modified montmorillonites on properties of silicone rubber-based ceramizable composites. J Therm Anal Calorim. 2015;119:111–21. https://doi.org/10.1016/j.ceramint.2012.07.109.

Wang JH, Ji CT, Yan YT, Zhao D, Shi LY. Mechanical and ceramifiable properties of silicone rubber filled with different inorganic fillers. Polym Degrad Stabil. 2015;121:149–56. https://doi.org/10.1016/j.polymdegradstab.2015.09.003.

Hu S, Chen F, Li JG, Shen Q, Huang ZX, Zhang L. The ceramifying process and mechanical properties of silicone rubber/ammonium polyphosphate/aluminium hydroxide/mica composites. Polym Degrad Stabil. 2016;126:196–203. https://doi.org/10.1016/j.polymdegradstab.2016.02.010.

Guo JH, Gao W, Wang Y, Liang D, Li HJ, Zhang X. Effect of glass frit with low softening temperature on the properties, microstructure and formation mechanism of polysiloxane elastomer-based ceramizable composites. Polym Degrad Stabil. 2017;136:71–9. https://doi.org/10.1016/j.polymdegradstab.2016.12.012.

Shi MX, Chen X, Fan SS, Shen S, Liu TX, Huang ZX. Fluxing agents on ceramification of composites of MgO-Al2O3-SiO2/Boron phenolic resin. J of Wuhan University of Technology Mater Sci. 2018;33:381–8. https://doi.org/10.1007/s11595-018-1833-8.

Mansouri J, Wood CA, Roberts K, Cheng YB, Burford RP. Investigation of the ceramifying process of modified silicone–silicate compositions. J Mater Sci. 2007;42:6046–55. https://doi.org/10.1007/s10853-006-1163-8.

Di HW, Deng C, Li RM, Dong LP, Wang YZ. A novel EVA composite with simultaneous flame retardation and ceramifiable capacity. Rsc Adv. 2015;5:51248–57. https://doi.org/10.1039/C5RA05781G.

Imiela M, Anyszka R, Bieliński DM, Pędzich Z, Zarzecka NM, Szumera M. Effect of carbon fibers on thermal properties and mechanical strength of ceramizable composites based on silicone rubber. J Therm Anal Calorim. 2016;124:197–203. https://doi.org/10.1007/s10973-015-5115-x.

Lou FP, Wu K, Wang Q, Qian ZY, Li SJ, Guo WH. Improved flame-retardant and ceramifiable properties of EVA composites by combination of ammonium polyphosphate and aluminum hydroxide. Polymers. 2019;11:125. https://doi.org/10.3390/polym11010125.

Zhao D, Shen YC, Wang T. Ceramifiable EVA/APP/SGF composites for improved ceramifiable properties. Polym Degrad Stabil. 2018;150:140–7. https://doi.org/10.1016/j.polymdegradstab.2018.02.006.

Gong XH, Shen YC, Wang TW. Improved ceramifiable properties of EVA composites with whitened and capsulized red phosphorus (WCRP). RSC Adv. 2016;6:96984–9. https://doi.org/10.1039/C6RA22126B

Gong XH, Wu TY, Ma J, Zhao D, Shen YC, Wang TW. Improved self-supporting property of ceramifying silicone rubber composites by forming crystalline phase at high temperatures. J Alloy Compd. 2017;706:322–9. https://doi.org/10.1016/j.jallcom.2017.02.252.

Gong XH, Wang TW. Optimisation of the ceramic-like body for ceramifiable EVA-based composites. Sci Eng Compos Mater. 2017;24:599–607. https://doi.org/10.1515/secm-2015-0093.

Lou FP, Yan W, Guo WH, Wei T, Li QY. Preparation and properties of ceramifiable flame-retarded silicone rubber composites. J Therm Anal Calorim. 2017;130:813–21. https://doi.org/10.1007/s10973-017-6448-4.

Dong LP, Deng C, Li RM, Cao ZJ, Lin L, Che L, Wang YZ. Poly (piperazinyl phosphamide): a novel highly-efficient charring agent for an EVA/APP intumescent flame retardant system. Rsc Adv. 2016;6:30436–44. https://doi.org/10.1039/C6RA00164E

Liao SF, Deng C, Huang SC, Cao JY, Wang YZ. An efficient halogen-free flame retardant for polyethylene: piperazine modified ammonium polyphosphates with different structures. Chinese J Polym Sci. 2016;34:1339–53. https://doi.org/10.1007/s10118-016-1855-8

Kong QH, Sun YL, Zhang CJ, Guan HM, Zhang JH, Wang DY, Zhang F. Ultrathin iron phenyl phosphonate nanosheets with appropriate thermal stability for improving fire safety in epoxy. Compos Sci Technol. 2019;182:107748. https://doi.org/10.1016/j.compscitech.2019.107748.

Yu ZL, et al. Fire-retardant and thermally insulatingphenolic-silica aerogels. Angewandte Chemie Int Edition. 2018;57:4538–42. https://doi.org/10.1002/anie.201711717.

Yang XT, Tang L, Guo YQ, Liang CB, Zhang Q, Kou KC, Gu JW. Improvement of thermal conductivities for PPS dielectric nanocomposites via incorporating NH2-Poss functionalized nBN fillers. Compos Part A. 2017;101:237–42. https://doi.org/10.1016/j.compositesa.2017.06.005.

Zhang YW, Shen YC, Shi KX, Wang TW, Harkin JE. Constructing a filler network for thermal conductivity enhancement in epoxy composites via reaction-induced phase separation. Compos Part A. 2018;110:62–9. https://doi.org/10.1016/j.compositesa.2018.04.009

Xiong YL, Shen Q, Chen F, Luo GQ, Yu K, Zhang LM. High strength retention and dimensional stability of silicone/alumina composite panel under fire. Fire Mater. 2012;36:254–63. https://doi.org/10.1002/fam.1107.

Anyszka R, Bielinski DM, Pedzich Z, Rybinski P, Imiela M, Sicinski M, Zarzecka-Napierała M, Gozdek T, Rutkowski P. Thermal stability and flammability of styrene-butadiene rubber-based (SBR) ceramifiable composites. Materials. 2016;9:604–16. https://doi.org/10.3390/polym9110615.

Xu J, Wang YJ, Tan Y, Qi M, Chen L, Wang YZ. A novel and feasible approach for one-pack flame-retardant epoxy resin with long pot life and fast curing. Chem Eng J. 2018;337:30–9. https://doi.org/10.1016/j.cej.2017.12.086.

Jiang WZ, Hao JW, Han ZD. Study on the thermal degradation of mixtures of ammonium polyphosphate and a novel caged bicyclic phosphate and their flame retardant effect in polypropylene. Polym Degrad Stabil. 2012;97:632–7. https://doi.org/10.1016/j.polymdegradstab.2012.01.001.

Cinausero N, Azema N, Lopez-Cuesta JM, Cochez M, Ferriol M. Synergistic effect between hydrophobic oxide nanoparticles and ammonium polyphosphate on fire properties of polymethyl methacrylate and polystyrene. Polym Degrad Stabil. 2011;96:1445–54. https://doi.org/10.1016/j.polymdegradstab.2011.05.008.

Kanai H, Sullivan V, Auerbach A. Impact modification of engineering thermoplastics. J Appl Polym Sci. 1994;53:527–41. https://doi.org/10.1002/app.1994.070530507.

Hsiue GH, Wei HF, Shiao SJ, Kuo WJ, Sha YA. Chemical modification of dicyclopentadiene-based epoxy resins to improve compatibility and thermal properties. Polym Degrad Stabil. 2001;73:309–18. https://doi.org/10.1016/S0141-3910(01)00092-1.

Ye CS, Chen LX, Bai XG, Bao XT. Research progress of flame retardant silicon-containing epoxy resin system. Shanxi Chemical Industry. 2009;29:33–7.

Wu CL, Wang BB, Tao R, Fang LW, Li HX. Study of mineral structure transformation of coal Ash with high ash melting temperature by XPS. Spectrosc Spectr Anal. 2018;38:2296–301. https://doi.org/10.3964/j.issn.1000-0593(2018)07-2296-06.

Dong S, Pang X. Xps analysis of phosphorylation layer on iron surface. Mater Protec. 1984;10:16577.

Ma HB, Li J, Ren TH. Tribological behavior s and film analysis of two ashless phosphorus/sulfur-containing additives in rapeseed oil. Acta Phys Chim Sin. 2008;24:799–804.

Mansouri J, Burford RP, Cheng YB. Pyrolysis behaviour of silicone-based cer-amifying composites. Mater Sci Eng A Struct Mater Proper Microstruct Process. 2006;425(1–2):7–14. https://doi.org/10.1016/j.msea.2006.03.047.

Honma T, Sato A, Ito N, Togashi T, Shinozaki K, Komatsu T. Crystallization behavior of sodium iron phosphate glass for sodium ion batteries. J Non-Cryst Solids. 2014;404:26–31. https://doi.org/10.1016/j.jnoncrysol.2014.07.028.

Dong WX, Bao QF, Gu X, Shen H, Yang J. Dry-pressing preparation of mullite columnar structure using waste gangue during firing and its properties. J Ceram Soc Jpn. 2017;125:75–8. https://doi.org/10.2109/jcersj2.16258.

Ou YX. Flame retardant. 4th ed. Beijing: National Defense Industry Press; 2009.

Levchik SV, Camino G, Levchik GF, Costa L. Mechanism of action of phosphorus-based flame retardants in nylon 6. I. ammonium polyphosphate. Fire Mater. 1995;19:1–10.

Zhang QT. Inorganic materials science foundation. 1st ed. Shanghai: East China University Sci Tech Press; 2007.

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (No. 51703096), China Postdoctoral Science Foundation (2018M64229), the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD) and Industry Foresight and Generic Key Technology of Suqian (H201816).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, D., Liu, W., Shen, Y. et al. A novel ceramifiable epoxy composite with enhanced fire resistance and flame retardance. J Therm Anal Calorim 147, 181–193 (2022). https://doi.org/10.1007/s10973-020-10200-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10200-4