Abstract

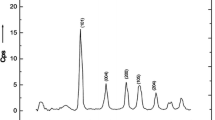

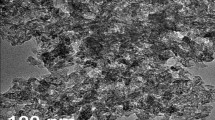

The experimental studies on Al2O3 + TiO2 hybrid nanofluid flowing under the turbulent condition in a double-tube heat exchanger with various modified V-cuts twisted tape inserts are performed to study the hydrothermal characteristics. The hybrid nanofluid is prepared with a volume concentration of 0.1% by dispersing Al2O3 and TiO2 nanoparticles by equal volume ratio in distilled water. The effect of using twisted tape turbulator (with and without V-cuts) and hybrid nanofluid on the heat transfer and pressure drop characteristics are evaluated for different twist ratios, V-cut depth ratios, V-cut width ratios and hybrid nanofluid inlet temperatures. Results show that Nusselt number as well as friction factor increases with the decrease in twisting ratio, increase in depth ratio, decrease in width ratio and decrease in nanofluid inlet temperature. Maximum improvements in 132% for Nusselt number and 55% for friction factor are obtained as compared to that for the water in the tube without twisted tape. The values of thermal performance factor and entropy generation ratio are greater than unity for hybrid nanofluid for all modified twisted tape inserts.

Similar content being viewed by others

Abbreviations

- EGR:

-

Entropy generation ratio

- DR:

-

Depth ratio

- LMTD:

-

Log mean temperature difference

- TR:

-

Twist ratio

- TPF:

-

Thermal performance factor

- SEM:

-

Scanning electron microscope

- WR:

-

Width ratio

- \(c_{\text{p}}\) :

-

Specific heat capacity (J kg−1 K−1)

- d :

-

Diameter (m)

- D :

-

Width of the tape (m)

- f :

-

Friction factor (–)

- H :

-

Pitch of the tape (m)

- k :

-

Thermal conductivity (W K−1 m−1)

- Nu:

-

Nusselt number (–)

- m :

-

Mass flow rate (kg s−1)

- Pr:

-

Prandtl number (–)

- Q :

-

Heat transfer rate (W)

- Re:

-

Reynolds number (–)

- S :

-

Entropy (W K−1)

- T :

-

Temperature (K)

- V :

-

Volume flow rate (lph)

- \(\Delta p\) :

-

Pressure drop (Pa)

- \(\emptyset\) :

-

Particle volume concentration (%)

- µ :

-

Dynamic viscosity (Pa s)

- \(\rho\) :

-

Density (kg m−3)

- bf:

-

Base fluid

- c:

-

Cold side

- f:

-

Friction

- gen:

-

Generation

- hnf:

-

Hybrid nanofluid

- ht:

-

Heat transfer

- i, o:

-

Inner/outer

- in, out:

-

Inlet and outlet

- np:

-

Nanoparticle

- it, ot:

-

Inner tube and outer tube

References

Hamid KA, Azmi WH, Mamat R, Sharma KV. Heat transfer performance of TiO2–SiO2 nanofluids in a tube with wire coil inserts. Appl Therm Eng. 2019;152:275–86.

Herring NR, Heister SD. On the use of wire-coil inserts to augment tube heat transfer. J Enhanced Heat Transf. 2009;16:19–34.

Eiamsa-Ard S, Kongkaitpaiboon V, Promvonge P. Thermal performance assessment of turbulent tube flow through wire coil turbulators. Heat Transf Eng. 2011;32:957–67.

Naik MT, Fahad SS, Sundar LS, Singh MK. Comparative study on thermal performance of twisted tape and wire coil inserts in turbulent flow using CuO/water nanofluid. Exp Therm Fluid Sci. 2014;57:65–76.

Reddy MCS, Rao VV. Experimental investigation of heat transfer coefficient and friction factor of ethylene glycol water based TiO2 nanofluid in double pipe heat exchanger with and without helical coil inserts. Int Commun Heat Mass Transf. 2014;50:68–76.

Mohammed HA, Hasan HA, Wahid MA. Heat transfer enhancement of nanofluids in a double pipe heat exchanger with louvered strip inserts. Int Commun Heat Mass Transf. 2013;40:36–46.

Kumar NTR, Bhramara P, Sundar LS, Singh MK, Sousa ACM. Heat transfer, friction factor and effectiveness of Fe3O4 nanofluid flow in an inner tube of double pipe U-bend heat exchanger with and without longitudinal strip inserts. Exp Therm Fluid Sci. 2017;85:331–43.

Arulprakasajothi M, Elangovan K, Chandrasekhar U, Suresh S. Performance study of conical strip inserts in tube heat exchanger using water based titanium oxide nanofluid. Therm Sci. 2018;22:477–85.

Karakaya H, Durmus A. Heat transfer and exergy loss in conical spring turbulators. Int J Heat Mass Transf. 2013;60:756–62.

Muthusamy C, Vivar M, Skryabin I, Srithar K. Effect of conical cut-out turbulators with internal fins in a circular tube on heat transfer and friction factor. Int Commun Heat Mass Transf. 2013;44:64–8.

Mohammed HA, Abuobeida IAMA, Vuthaluru HB, Liu S. Two-phase forced convection of nanofluids flow in circular tubes using convergent and divergent conical rings inserts. Int Commun Heat Mass Transf. 2019;101:10–20.

Wijayanta AT, Istanto T, Kariya K, Miyara A. Heat transfer enhancement of internal flow by inserting punched delta winglet vortex generators with various attack angles. Exp Therm Fluid Sci. 2017;87:141–8.

Lei Y, Zheng F, Song C, Lyu Y. Improving the thermal hydraulic performance of a circular tube by using punched delta-winglet vortex generators. Int J Heat Mass Transf. 2017;111:299–311.

Wijayanta AT, Yaningsih I, Aziz M, Miyazaki T, Koyama S. Double-sided delta-wing tape inserts to enhance convective heat transfer and fluid flow characteristics of a double-pipe heat exchanger. Appl Therm Eng. 2018;145:27–37.

Rashidi S, Zade NM, Esfahani JA. Thermo-fluid performance and entropy generation analysis for a new eccentric helical screw tape inserts in a 3D tube. Chem Eng Process. 2017;117:27–37.

Zade NM, Akar S, Rashidi S, Esfahani JA. Thermo-hydraulic analysis for a novel eccentric helical screw tape insert in a three dimensional tube. Appl Therm Eng. 2017;124:413–21.

Zade NM, Akar S, Rashidi S, Esfahani JA. Potential of gear-ring turbulator in three-dimensional heat exchanger tube from second law of thermodynamic viewpoint. Int J Numer Methods Heat Fluid Flow. 2019;29:1526–43.

Jiao F, Deng X-H. Heat transfer enhancement in the shell side of the self-support in rectangular converging-diverging tube bundle heat exchangers with different inserts. Heat Transf Res. 2012;43:615–31.

Ramakumar BVN, Arsha JD, Tayal P. Tapered twisted tape inserts for enhanced heat transfer. J Heat Transf. 2016;138:011901.

Nakhchi ME, Esfahani JA. Cu-water nanofluid flow and heat transfer in a heat exchanger tube equipped with cross-cut twisted tape. Powder Technol. 2018;339:985–94.

Ponnada S, Subrahmanyam T, Naidu SV. A comparative study on the thermal performance of water in a circular tube with twisted tapes, perforated twisted tapes and perforated twisted tapes with alternate axis. Int J Therm Sci. 2019;136:530–8.

Abolarin SM, Everts M, Meyer JP. Heat transfer and pressure drop characteristics of alternating clockwise and counter clockwise twisted tape inserts in the transitional flow regime. Int J Heat Mass Transf. 2019;133:203–17.

Datt R, Bhist MS, Kotiyal AD, Maithani R, Kumar A. Development of new correlations for heat transfer and friction loss of solid ring with combined square wing twisted tape inserts heat exchanger tube. Exp Heat Transf. 2019;32:179–200.

Arshad W, Ali HM. Experimental investigation of heat transfer and pressure drop in a straight minichannel heat sink using TiO2 nanofluid. Int J Heat Mass Transf. 2017;110:248–56.

Arshad W, Ali HM. Graphene nanoplatelets nanofluids thermal and hydrodynamic performance on integral fin heat sink. Int J Heat Mass Transf. 2017;107:995–1001.

Sajid MU, Ali HM. Recent advances in application of nanofluids in heat transfer devices: a critical review. Renew Sustain Energy Rev. 2019;103:556–92.

Sundar LS, Singh MK, Sousa ACM. Enhanced heat transfer and friction factor of MWCNT–Fe3O4/water hybrid nanofluids. Int Commun Heat Mass Transf. 2014;52:73–83.

Yarmand H, Gharehkhani S, Ahmadi G, Shirazi SFS, Baradaran S, Montazer E, Zubir MNM, Alehashem MS, Kazi SN, Dahari M. Graphene nanoplatelets–silver hybrid nanofluids for enhanced heat transfer. Energy Convers Manag. 2015;100:419–28.

Laein RP, Rashidi S, Esfahani JA. Experimental investigation of nanofluid free convection over the vertical and horizontal flat plates with uniform heat flux by PIV. Adv Powder Technol. 2016;27:312–22.

Rashidi S, Bovand M, Esfahani JA. Opposition of Magnetohydrodynamic and Al2O3–water nanofluid flow around a vertex facing triangular obstacle. J Mol Liq. 2016;215:276–84.

Shirejini SZ, Rashidi S, Esfahani JS. Recovery of drop in heat transfer rate for a rotating system by nanofluids. J Mol Liq. 2016;220:961–9.

Khan MS, Abid M, Ali HM, Amber KP, Bashir MA, Javed S. Comparative performance assessment of solar dish assisted s-CO2 Brayton cycle using nanofluids. Appl Therm Eng. 2019;148:295–306.

Bhattad A, Sarkar J, Ghosh P. Improving the performance of refrigeration systems by using nanofluids: a comprehensive review. Renew Sustain Energy Rev. 2018;82:3656–69.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Siavashi M, Taylor RA, Niazmand H, Wongwises S, Hayat T, Kolanjiyil A, Kasaeian A, Pop I. Recent advances in modeling and simulation of nanofluid flows—part I: fundamentals and theory. Phys Rep. 2019;790:1–48.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Taylor RA, Abu-Nada E, Rashidi S, Niazmand H, Wongwises S, Hayat T, Kasaeian A, Pop I. Recent advances in modeling and simulation of nanofluid flows—part II: applications. Phys Rep. 2019;791:1–59.

Ali HM, Babar H, Shah TR, Sajid MU, Qasim MA, Javed S. Preparation techniques of TiO2 nanofluids and challenges: a review. Appl Sci. 2018;8:587.

Sajid MU, Ali HM. Thermal conductivity of hybrid nanofluids: a critical review. Int J Heat Mass Transf. 2018;126:211–34.

Han ZH, Yang B, Kim SH, Zachariah MR. Application of hybrid sphere/carbon nanotube particles in nanofluids. Nanotechnology. 2007;18:105701.

Sundar LS, Kumar NTR, Naik MT, Sharma KV. Effect of full length twisted tape inserts on heat transfer and friction factor enhancement with Fe3O4 magnetic nanofluid inside a plain tube: an experimental study. Int J Heat Mass Transf. 2012;55:2761–8.

Maddah H, Alizadeh M, Ghasemi N, Alwi SRW. Experimental study of Al2O3/water nanofluid turbulent heat transfer enhancement in the horizontal double pipes fitted with modified twisted tapes. Int J Heat Mass Transf. 2014;78:1042–54.

Esmaeilzadeh E, Almohammadi H, Nokhosteen A, Motezaker A, Omrani AN. Study on heat transfer and friction factor characteristics of γ-Al2O3/water through circular tube with twisted tape inserts with different thicknesses. Int J Therm Sci. 2014;82:72–83.

Hazbehian M, Maddah H, Mohammadiun H, Alizadeh M. Experimental investigation of heat transfer augmentation inside double pipe heat exchanger equipped with reduced width twisted tapes inserts using polymeric nanofluid. Heat Mass Transf. 2016;52:2515–29.

Kumar NTR, Bhramara P, Kirubeil A, Sundar LS, Singh MK, Sousa ACM. Effect of twisted tape inserts on heat transfer, friction factor of Fe3O4 nanofluids flow in a double pipe U-bend heat exchanger. Int Commun Heat Mass Transf. 2018;95:53–62.

Sarkar J, Ghosh P, Adil A. A review on hybrid nanofluids: recent research, development and applications. Renew Sustain Energy Rev. 2015;43:164–77.

Kumar V, Sarkar J. Research and development on composite nanofluids as next-generation heat transfer medium. J Therm Anal Calorim. 2019;137:1133–54.

Madhesh D, Parameshwaran R, Kalaiselvam S. Experimental investigation on convective heat transfer and rheological characteristics of Cu–TiO2 hybrid nanofluids. Exp Therm Fluid Sci. 2014;52:104–15.

Maddah H, Aghayari R, Mirzaee M, Ahmadi MH, Sadeghzadeh M, Chamkha AJ. Factorial experimental design for the thermal performance of a double pipe heat exchanger using Al2O3–TiO2 hybrid nanofluid. Int Commun Heat Mass Transf. 2018;97:92–102.

Shahsavar A, Godini A, Sardari PT, Toghraie D, Salehipour H. Impact of variable fluid properties on forced convection of Fe3O4/CNT/water hybrid nanofluid in a double-pipe mini-channel heat exchanger. J Therm Anal Calorim. 2019;137:1031–43.

Bahiraei M, Mazaheri N, Rizehvandi A. Application of a hybrid nanofluid containing graphene nanoplatelet–platinum composite powder in a triple-tube heat exchanger equipped with inserted ribs. Appl Therm Eng. 2019;149:588–601.

Kumar V, Sarkar J. Numerical and experimental investigations on heat transfer and pressure drop characteristics of Al2O3–TiO2 hybrid nanofluid in minichannel heat sink with different mixture ratio. Powder Technol. 2019;345:717–27.

Kline SJ, McClintock FA. Describing uncertainties in single-sample experiments. Mech Eng. 1953;75:3–8.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Uncertainty analysis

Appendix: Uncertainty analysis

Rights and permissions

About this article

Cite this article

Singh, S.K., Sarkar, J. Improving hydrothermal performance of double-tube heat exchanger with modified twisted tape inserts using hybrid nanofluid. J Therm Anal Calorim 143, 4287–4298 (2021). https://doi.org/10.1007/s10973-020-09380-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09380-w