Abstract

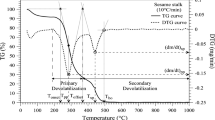

In this work, the physicochemical and thermomechanical characteristics of date seeds were examined during their pyrolysis under inert atmosphere from room temperature to 600 °C. We first discuss the thermal analysis characterization including TG/DTG, DTA, and DSC analyses and then the thermomechanical aspects related to fixed bed heat treatments, dimensional variations measurements, and SEM characterizations. TG allowed us to delimit the different zones of the pyrolysis of date seeds. Thus, an active pyrolysis zone between 120 and 410 °C is related hemicelluloses decomposition, followed by the degradation of cellulose. Lignin decomposes slowly throughout all the temperature range. All these degradations and reactions are suggested by the different peaks of the mass loss derivative. The DTA and DSC analyses indicate that the thermal stress of date seeds is exothermic. This exothermicity is related to the internal frictions representative of the thermomechanical behavior of the thermally stressed material. Dimensional variation measurements show that the material generally shrinks with slight increases in volume. These phenomena are well evidenced by the characterization by SEM indicating the development of a plastic phase by crazing and shear mainly in volume and the formation of cracks on surface. The development of this phase occurred mainly during the first warming of the material by DSC.

Similar content being viewed by others

References

Harrak H, Boujnah MM. Valorisation technologique des dattes au Maroc, Institut National de Recherche Agronomique INRA, 2012.

Directives stratégiques pour la filière phoénicicole, Direction de la Stratégie et des Statistiques, Département de l’Agriculture 2018. http://www.agriculture.gov.ma/pages/veille/directives-strategiques-pour-la-filiere-phoenicicole.

Hossain MZ, Waly MI, Singh V, Sequeira V, Shafiur Rahman M. Chemical composition of date-pits and its potential for developing value-added product—a review. Pol J Food Nutr Sci. 2014;64(4):215–26.

Besbes S, Blecker C, Deroanne C, Bahloul N, Lognay G, Derira N, Attia H. Date seed oil: phenolic, tocopherol and sterol profiles. J Food Lipids. 2004;11:251–65.

AOAC (1995). Official methods of analysis of AOAC international, Virginia (16th ed., Vol. 2).

AOAC. Official Methods of Analyses. Washington, DC: Association of Official Analytical Chemist; 1997.

AOAC. Official methods of analysis. 17th ed. Washington, DC: Associate of Official Analytical Chemist; 2000.

Kifani-Sahban F, Kifani A, Belkbir L, Zoulalian A, Arauso J, Cordero T. A physical approach in the understanding of the phenomena accompanying the thermal treatment of lignin. Thermochim Acta. 1997;298:199–204.

Kifani A, Sahban F. Mécanique des Milieux Continus. Paris: Publibook; 2014.

Walter G. Kauman, Le matériau bois – propriétés technologie. Mise en œuvre, Association pour la recherche sur le bois en Lorraine; 1983.

Khiari B, Abed I, Jeguirim M, Zagrouba F. Thermal conversion of date stones and palm stalks: experimental and kinetic study. In: Proceeding of the 11th international conference of environmental sciences and technology, Chania, Crete, Greece. 2009;B-448–B-455.

Carrier M, Loppinet-Serani A, Denux D, Lasnier JM, Ham-Pichavant F, Cansell F, Aymonier C. Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass Bioenergy. 2011;35(1):298–307.

Shah MA, Khan MNS, Kumar V. Biomass residue characterization for their potential application as biofuels. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7560-9.

Nakanishi M, Ogi T, Endo Y, Otaka M. Effect of carbonization temperature on composition of carbonized woody biomass. J Therm Anal Calorim. 2017;130(2):1117–23.

Abed I, Paraschiv M, Loubar K, Zagrouba F, Tazerout M. Palm waste pyrolysis analysis. BioResources. 2012;7(1):1200–20.

Babiker ME, Rashid A, Aziz A, Heikal M, Yusup S, Abakar M. Pyrolysis characteristics of Phoenix dactylifera date palm seeds using thermo-gravimetric analysis (TG). Int J Environ Sci Dev. 2013;4(5):521–4.

Cruz G, Santiago PA, Braz CEM, Seleghim P Jr, Crnkovic PM. Investigation into the physical–chemical properties of chemically pretreated sugarcane bagasse. J Therm Anal Calorim. 2018;132(2):1039–53.

Antal MJ Jr. Chapter 4 Biomass pyrolysis: a review of the literature Part 2: lignocellulose pyrolysis. In: Duffie JA, Boer KW, editors. Advances in solar energy, vol. 3. New York: Plenum; 1984. p. 175–255.

Ronkart SN, Blecker CS, Deroanne C, Paquot M. Phénomène de la transition vitreuse appliquée aux glucides alimentaires amorphes à l'état de poudre. Biotechnol Agron Soc Environ. 2009;13(1):177–86.

Kifani-Sahban F. Etude des aspects physiques et physico-chimiques de la pyrolyse lente de l’eucalyptus et des principaux constituants du bois. Thèse de Doctorat d’Etat, Faculté des Sciences Rabat (1997).

EL Moustaqim M, El Kaihal A, Men-La-Yakhaf S, Taibi M, Sebbahi S, El Hajjaji S, Kifani-Sahban F. Thermal and thermomechanical analysis of lignin. Sustain Chem Pharm. 2018;9:63–8.

Roberts AF, Clough G. In: 9th International symposium on combustion 1963;158–166.

Mc Kinney J.W. Paper trade journal 1964; 122 (4): 58.

Sinha S, Jhalani A, Ravi MR, Ray A. Modelling of pyrolysis in wood: a review. SESI J. 2000;10:41–62.

Hemati M, El ghezal L, Laguerie C. Etude Expérimentale de la Pyrolyse de Sciure de Bois Dans un Lit Fluidisé de Sable Entre 630 et 940°C. Chem Eng J. 1989;42:B25–38.

Aguiara L, Márquez-Montesinos F, Gonzalo A, Sánchez JL, Arauzo J. Influence of temperature and particle size on the fixed bed pyrolysis of orange peel residues. J Anal Appl Pyrol. 2008;83:124–30.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Table 2.

Rights and permissions

About this article

Cite this article

El Abbari, H., Bentahar, S., El Marouani, M. et al. Thermal and thermomechanical behavior of Moroccan Boufeggous variety date seeds. J Therm Anal Calorim 137, 1485–1492 (2019). https://doi.org/10.1007/s10973-019-08060-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08060-8