Abstract

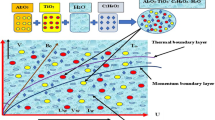

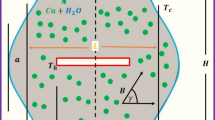

In this research, nanofluid heat transfer enhancement in a pipe by means of twisted tape with alternate axis is presented. Finite volume method is selected as simulation tool. Influences of revolution angle and Reynolds number on nanofluid hydrothermal treatment have been demonstrated. Suitable formulas for Nusselt number and Darcy factor are provided. Results prove that temperature gradient augments with enhance of revolution angle because of increase in secondary flow but pressure loss augments with rise of revolution angle.

Similar content being viewed by others

Abbreviations

- \( D \) :

-

Pipe diameter (mm)

- \( f \) :

-

Darcy friction factor

- \( L \) :

-

Length of pipe (mm)

- \( b \) :

-

Height of the twisted (mm)

- \( Nu \) :

-

Nusselt number

- \( t \) :

-

Thickness of the fin (mm)

- Pr :

-

Prandtl number

- \( P \) :

-

Pressure (Pa)

- \( p \) :

-

Twisted pitch length

- \( T \) :

-

Fluid temperature (K)

- Re :

-

Reynolds number

- \( \alpha \) :

-

Thermal diffusivity (m2 s−1)

- \( \mu \) :

-

Dynamic viscosity of nanofluid (Pa s)

- \( \beta \) :

-

Revolution angle

- \( \rho \) :

-

Density (kg m−3)

- \( \phi \) :

-

Volume fraction of nanofluid

- f:

-

Base fluid

- s:

-

Particles

- nf:

-

Nanofluid

References

Zeeshan A, Majeed A, Ellahi R. Effect of magnetic dipole on viscous ferro-fluid past a stretching surface with thermal radiation. J Mol Liq. 2016;215:549–54.

Brar LK, Singla G, Kaur N, Pandey OP. Thermal stability and structural properties of Ta nanopowder synthesized via simultaneous reduction of Ta2O5 by hydrogen and carbon. J Therm Anal Calorim. 2015;119(1):453–60.

Akar S, Rashidi S, Esfahani JA. Second law of thermodynamic analysis for nanofluid turbulent flow around a rotating cylinder. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6907-y.

Sheikholeslami M, Ellahi R. Three dimensional mesoscopic simulation of magnetic field effect on natural convection of nanofluid. Int J Heat Mass Transf. 2015;89:799–808.

Rashidi S, Mahian O, Languri EM. Applications of nanofluids in condensing and evaporating systems. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6773-7.

Sheikholeslami M, Shehzad SA. Thermal radiation of ferrofluid in existence of Lorentz forces considering variable viscosity. Int J Heat Mass Transf. 2017;109:82–92.

Sheikholeslami M, Seyednezhad M. Simulation of nanofluid flow and natural convection in a porous media under the influence of electric field using CVFEM. Int J Heat Mass Transf. 2018;120:772–81.

Sheikholeslami M, Rokni HB. Numerical simulation for impact of Coulomb force on nanofluid heat transfer in a porous enclosure in presence of thermal radiation. Int J Heat Mass Transf. 2018;118:823–31.

Shirejini SZ, Rashidi S, Esfahani JA. Recovery of drop in heat transfer rate for a rotating system by nanofluids. J Mol Liq. 2016;220:961–9.

Sheikholeslami M, Shehzad SA. Numerical analysis of Fe3O4–H2O nanofluid flow in permeable media under the effect of external magnetic source. Int J Heat Mass Transf. 2018;118:182–92.

Sheikholeslami M, Shamlooei M, Moradi R. Numerical simulation for heat transfer intensification of nanofluid in a permeable curved enclosure considering shape effect of Fe3O4 nanoparticles. Chem Eng Process. 2018;124:71–82.

Rashidi S, MoghadasZade N, AbolfazliEsfahani J. Thermo-fluid performance and entropy generation analysis for a new eccentric helical screw tape insert in a 3D tube. Chem Eng Process. 2017;117:27–37.

Sheremet MA, Oztop HF, Pop I. MHD natural convection in an inclined wavy cavity with corner heater filled with a nanofluid. J Magn Magn Mater. 2016;416:37–47.

Zade NM, Akar S, Rashidi S, Esfahani JA. Thermo-hydraulic analysis for a novel eccentric helical screw tape insert in a three dimensional tube. Appl Therm Eng. 2017;124:413–21.

Sheikholeslami M, Shehzad SA. Magnetohydrodynamic nanofluid convection in a porous enclosure considering heat flux boundary condition. Int J Heat Mass Transf. 2017;106:1261–9.

Sheikholeslami M. Numerical investigation of nanofluid free convection under the influence of electric field in a porous enclosure. J Mol Liq. 2018;249:1212–21.

Sheikholeslami M, Ganji DD, Javed MY, Ellahi R. Effect of thermal radiation on magnetohydrodynamics nanofluid flow and heat transfer by means of two phase model. J Magn Magn Mater. 2015;374:36–43.

Sheikholeslami M. CuO–water nanofluid flow due to magnetic field inside a porous media considering Brownian motion. J Mol Liq. 2018;249:921–9.

Sheikholeslami M, Shehzad SA. Simulation of water based nanofluid convective flow inside a porous enclosure via non-equilibrium model. Int J Heat Mass Transf. 2018;120:1200–12.

Sheikholeslami M. Numerical investigation for CuO–H2O nanofluid flow in a porous channel with magnetic field using mesoscopic method. J Mol Liq. 2018;249:739–46.

Sheikholeslami M. Influence of magnetic field on nanofluid free convection in an open porous cavity by means of lattice Boltzmann method. J Mol Liq. 2017;234:364–74.

Sheikholeslami M, Sadoughi MK. Simulation of CuO–water nanofluid heat transfer enhancement in presence of melting surface. Int J Heat Mass Transf. 2018;116:909–19.

Sheikholeslami Kandelousi M. KKL correlation for simulation of nanofluid flow and heat transfer in a permeable channel. Phys Lett A. 2014;378(45):3331–9.

Kim D, Kwon Y, Cho Y, Li C, Cheong S, Hwang Y, Lee J, Hong D, Moona S. Convective heat transfer characteristics of nanofluids under laminar and turbulent flow conditions. Curr Appl Phys. 2009;9:e119–23.

Aminossadati SM, Raisi A, Ghasemi B. Effects of magnetic field on nanofluid forced convection in a partially heated micro channel. Int J Non Linear Mech. 2011;46:1373–82.

Sheikholeslami M, Darzi M, Sadoughi MK. Heat transfer improvement and pressure drop during condensation of refrigerant-based nanofluid; an experimental procedure. Int J Heat Mass Transf. 2018;122:643–50.

Sheikholeslami M, Ganji DD, Rashidi MM. Magnetic field effect on unsteady nanofluid flow and heat transfer using Buongiorno model. J Magn Magn Mater. 2016;416:164–73.

Sheikholeslami M, Rashidi MM, Hayat T, Ganji DD. Free convection of magnetic nanofluid considering MFD viscosity effect. J Mol Liq. 2016;218:393–9.

Sheikholeslami M, Rashidi MM, Ganji DD. Numerical investigation of magnetic nanofluid forced convective heat transfer in existence of variable magnetic field using two phase model. J Mol Liq. 2015;212:117–26.

Sheikholeslami M, Vajravelu K, Rashidi MM. Forced convection heat transfer in a semi annulus under the influence of a variable magnetic field. Int J Heat Mass Transf. 2016;92:339–48.

Sheikholeslami M, Rashidi MM, Ganji DD. Effect of non-uniform magnetic field on forced convection heat transfer of Fe3O4–water nanofluid. Comput Methods Appl Mech Eng. 2015;294:299–312.

Sheikholeslami M, Rashidi MM. Ferrofluid heat transfer treatment in the presence of variable magnetic field. Eur Phys J Plus. 2015;130:115. https://doi.org/10.1140/epjp/i2015-15115-4.

Sheikholeslami M, Rashidi MM. Effect of space dependent magnetic field on free convection of Fe3O4–water nanofluid. J Taiwan Inst Chem Eng. 2015;56:6–15.

Sheikholeslami M, Ganji DD, Rashidi MM. Ferrofluid flow and heat transfer in a semi annulus enclosure in the presence of magnetic source considering thermal radiation. J Taiwan Inst Chem Eng. 2015;47:6–17.

Sheikholeslami M, Rokni HB. CVFEM for effect of Lorentz forces on nanofluid flow in a porous complex shaped enclosure by means of non-equilibrium model. J Mol Liq. 2018;254:446–62.

Sheikholeslami M, Rokni HB. Magnetic nanofluid flow and convective heat transfer in a porous cavity considering Brownian motion effects. Phys Flu. 2018;30(1). https://doi.org/10.1063/1.5012517.

Sheikholeslami M, Rokni HB. Simulation of nanofluid heat transfer in presence of magnetic field: a review. Int J Heat Mass Transf. 2017;115:1203–33.

Acknowledgements

This research was supported by the National Sciences Foundation of China (NSFC) (No. U1610109), Yingcai Project of CUMT (YC2017001), PAPD and UOW Vice-Chancellor’s Postdoctoral Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jafaryar, M., Sheikholeslami, M., Li, Z. et al. Nanofluid turbulent flow in a pipe under the effect of twisted tape with alternate axis. J Therm Anal Calorim 135, 305–323 (2019). https://doi.org/10.1007/s10973-018-7093-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7093-2