Abstract

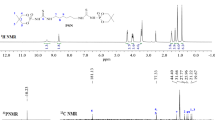

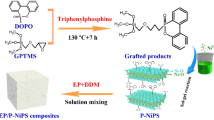

In this work, renewable diphenolic acid was used to prepare reactive phosphorus-containing epoxy monomer (PCDGEDP) and its chemical structure was characterized by FTIR, 1H-NMR and 31P-NMR spectra. Subsequently, PCDGEDP was reacted with diaminodiphenylmethane (DDM) to obtain phosphorus-containing PCDGEDP/DDM thermoset. The performances of corresponding thermoset in terms of thermal stability, mechanical property, combustion performance and fire behavior have been investigated in detail. It is worth noting that phosphorus-containing PCDGEDP/DDM thermoset showed high glass transition temperature (127 °C), good thermal stability with high mass residue (16.1 % at 700 °C) as well as good mechanical properties. Meanwhile, phosphorus-containing PCDGEDP/DDM thermoset exhibited improved flame retardant property with UL-94V-0 grade and high LOI value (29.6 %). Moreover, incorporating reactive phosphorus-containing epoxy monomer PCDGEDP into epoxy network can significantly decrease the heat release rate, total heat release, smoke produce rate, total smoke release and therefore enhance the fire safety of epoxy thermoset during combustion. It is implying that incorporating rigid phenyldiphosphate structure into epoxy molecular backbone can impart flame retardancy and smoke suppression properties to epoxy thermoset. It is tightly related to its higher phosphorus content (3.3 %) and higher mass residue (18.53 %) of phosphorus-containing PCDGEDP/DDM thermoset.

Similar content being viewed by others

References

Auvergne R, Caillol S, David G, Boutevin B, Pascault JP. Biobased thermosetting epoxy: present and future. Chem Rev. 2014;114:1082–115.

Shieh JY, Ho TH, Wang CS. Aminosiloxane-modified epoxy resins as microelectronic encapsulants. Angew Makromol Chem. 1995;224:21–32.

Wang DZ. Production and application of epoxy resin. Beijing: Chemical Industry Press; 2001.

Lu SY, Hamerton I. Recent developments in the chemistry of halogen-free flame retardant polymers. Prog Polym Sci. 2002;27:1661–712.

Raquez JM, Deléglise M, Lacrampe MF, Krawczak P. Thermosetting (bio)materials derived from renewable resources: a critical review. Prog Polym Sci. 2010;35:487–509.

Flint S, Markle T, Thompson S, Wallace E. Bisphenol A exposure, effects, and policy: a wildlife perspective. J Environ Manag. 2012;104:19–34.

Werpy T, Petersen G. Top value added chemicals from biomass. Volume I—results of screening for potential candidates from sugars and synthesis gas, N. R. E. Laboratory Report DOE/GO-102004-1992, U.S. Department of Energy; 2004.

Bozell JJ, Moens L, Elliott DC, Wang Y, Neuenscwander GG, Fitzpatrick SW, Bilskid RJ, Jarnefelde JL. Production of levulinic acid and use as a platform chemical for derived products. Resour Conserv Recycl. 2000;28:227–39.

Zhang R, Moore J. Synthesis, characterization and properties of polycarbonate containing carboxyl side groups. Macromol Symp. 2003;199:375–90.

Blair RM, Fang H, Branham WS, Hass BS, Dial SL, Moland CL, Tong W, Shi L, Perkins R, Sheehan DM. The estrogen receptor relative binding affinities of 188 natural and xenochemicals: structural diversity of ligands. Toxicol Sci. 2000;54:138–53.

Ghosh NN, Kiskan B, Yagci Y. Polybenzoxazines-new high performance thermosetting resins: synthesis and properties. Prog Polym Sci. 2007;32:1344–91.

Zúñiga C, Bonnaud L, Lligadas G, Ronda JC, Galià M, Cádiza V, Dubois P. Convenient and solventless preparation of pure carbon nanotube/polybenzoxazine nanocomposites with low percolation threshold and improved thermal and fire properties. J Mater Chem A. 2014;2:6814–22.

Miranda T, Herman H. Epoxy resins based on diphenolic acid derivatives. U.S. Patent 3,296,160; 1967.

Maiorana A, Spinella S, Gross RA. Bio-based alternative to the diglycidyl ether of bisphenol A with controlled materials properties. Biomacromolecules. 2015;16:1021–31.

Levchik SV, Weil ED. Thermal decomposition, combustion and flame-retardancy of epoxy resins-a review of the recent literature. Polym Int. 2004;53:1901–29.

Carja ID, Serbezeanu D, Vlad-Bubulac T, Hamciuc C, Coroaba A, Lisa G, López CG, Soriano MF, Pérezd VF, Romero Sánchezd MD. A straightforward, eco-friendly and cost-effective approach towards flame retardant epoxy resins. J Mater Chem A. 2014;2:16230–41.

Liu J, Tang JY, Wang XD, Wu DZ. Synthesis, characterization and curing properties of a novel cyclolinear phosphazene-based epoxy resin for halogen-free flame retardancy and high performance. RSC Adv. 2012;2:5789–99.

Ménard R, Negrell-Guirao C, Ferry L, Sonnier R, David G. Synthesis of biobased phosphate flame retardants. Pure Appl Chem. 2014;86:1637–50.

Ma SQ, Liu XQ, Jiang YH, Fan LB, Feng JX, Zhu J. Synthesis and properties of phosphorus-containing bio-based epoxy resin from itaconic acid. Sci China Chem. 2014;57:379–88.

Ménard R, Negrell C, Fache M, Ferry L, Sonnier R, David G. From a bio-based phosphorus-containing epoxy monomer to fully bio-based flame-retardant thermosets. RSC Adv. 2015;5:70856–67.

Ma SQ, Liu XQ, Jiang YH, Tang ZB, Zhang CZ, Zhu J. Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem. 2013;15:245–54.

Liu YL, Hsiue GH, Chu YS. Synthesis, characterization, thermal, and flame retardant properties of phosphate-based epoxy resins. J Polym Sci A Polym Chem. 1997;5:565–74.

Lin CH, Wang CS. Novel phosphorus-containing epoxy resins. Part I. Synthesis and properties. Polymer. 2001;42:1869–78.

Gao LP, Wang DY, Wang YZ, Wang JS, Yang B. A flame-retardant epoxy resin based on a reactive phosphorus-containing monomer of DODPP and its thermal and flame-retardant properties. Polym Degrad Stab. 2008;93:1308–15.

Wang CS, Shieh JY. Phosphorus-containing epoxy resin for an electronic application. J Appl Polym Sci. 1999;73:353–61.

Nazaré S, Kandola B, Richard-Horrocks A. Use of cone calorimetry to quantify the burning hazard of apparel fabrics. Fire Mater. 2002;26:191–9.

Modestia M, Lorenzettia A, Simionia F, Checchinb M. Influence of different flame retardants on fire behavior of modified PIR/PUR polymers. Polym Degrad Stab. 2001;74:475–9.

Acknowledgements

This work is financially supported by the Jiangsu Province Natural Science Foundation of China (Grant No. BK20130071).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, L., Zheng, G., Nie, X. et al. Thermal performance, mechanical property and fire behavior of epoxy thermoset based on reactive phosphorus-containing epoxy monomer. J Therm Anal Calorim 127, 1419–1430 (2017). https://doi.org/10.1007/s10973-016-5456-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5456-0