Abstract

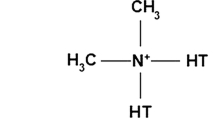

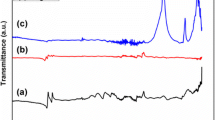

Various compositions of polypropylene (PP) and poly(lactic acid) (PLA) blends were prepared by one-step melt compounding in a twin-screw extruder. Two compositions were selected for investigation of effect of clay and n-butyl acrylate glycidyl methacrylate ethylene terpolymer (PTW) as compatibilizer on thermal properties and non-isothermal crystallization behavior of PP/PLA/clay nanocomposite systems, i.e., PP-rich one (75/25 composition) containing Cloisite 15A and PLA-rich one (25/75 composition) containing Cloisite 30B. The thermal behavior of the systems was investigated by means of differential scanning calorimetry (DSC) and correlated with their microstructures. The narrowing down of the peaks in the wide-angle X-ray scattering pattern of PP-rich blend was associated with an increase in size and/or perfection of the crystals. On the other hand, the broadening of the peaks in PLA-rich blend implied a decrease in the size of the crystals. The calculated interlayer distance, using Scherrer equation, in Cloisite 15A was slightly greater than that of Cloisite 30B. Moreover, an increase of 100 % in interlayer distance showed a greater level of intercalation in PP-rich system as compared to the PLA-rich system. Blending of PP and PLA led to significant changes in the crystallinity behavior of the blends compared to the neat components. Moreover, the incorporation of the both clays into the two systems led to a greater change in the crystallinity degree, comparing to that of unfilled blends.

Similar content being viewed by others

References

Kim K-W, Lee B-H, Kim H-J, Sriroth K, Dorgan JR. Thermal and mechanical properties of cassava and pineapple flours-filled PLA bio-composites. J Therm Anal Calorim. 2012;108(3):1131–9.

Shi N, Dou Q. Non-isothermal cold crystallization kinetics of poly(lactic acid)/poly(butylene adipate-co-terephthalate)/treated calcium carbonate composites. J Therm Anal Calorim. 2014;. doi:10.1007/s10973-014-4162-z.

Tábi T, Suplicz A, Czigány T, Kovács JG. Thermal and mechanical analysis of injection moulded poly(lactic acid) filled with poly(ethylene glycol) and talc. J Therm Anal Calorim. 2014;118:1419–30.

Parry RT. Principle and applications of modified atmosphere packaging of food. New York: Chapman & Hall; 1993.

Vieth WR. Diffusion in and through polymers: principles and applications, Chapter 4. New York: Oxford University Press; 1991.

Auras R, Harte B, Selke S. An overview of polylactides as packaging materials. Macromol Biosci. 2004;4:835–64.

Sarasua JR, Arraiza AL, Balerdi P, Maiza I. Crystallinity and mechanical properties of optically pure polylactides and their blends. Polym Eng Sci. 2005;45:745–53.

Tsuji H, Ikada Y. Crystallization from the melt of PLA with different optical purities and their blends. Macromol Chem Phys. 1996;197:3483–99.

Hutchinson M, Dorgan J, Knauss D, Hait S. Optical properties of polylactides. J Polym Environ. 2006;14:119–24.

Pyda M, Bopp RC, Wunderlich B. Heat capacity of poly(lactic acid). J Chem Thermodynam. 2004;36:731–42.

Dorgan JR, Jansen J, Clayton MP. Melt rheology of variable l-content poly(lactic acid). J Rheol. 2005;49:607–19.

Liang J-Z, Zhou L, Tang C-Y, Tsui C-P. Crystalline properties of poly(l-lactic acid) composites filled with nanometer calcium carbonate. Compos B-Eng. 2013;45:1646–50.

Zhao H, Cui Z, Wang X, Turng L-S, Peng X. Processing and characterization of solid and microcellular poly(lactic acid)/polyhydroxybutyrate-valerate (PLA/PHBV) blends and PLA/PHBV/clay nanocomposites. Compos B-Eng. 2013;51:79–91.

As’habi L, Jafari S H, Khonakdar H A, Häussler L, Wagenknecht U, Heinrich G, Non-isothermal crystallization behavior of PLA/LLDPE/nanoclay hybrid: Synergistic role of LLDPE and clay, Thermochim Acta. 2013;565:102–13.

Tábi T, Sajó IE, Szaból F, Luyt AS, Kovács JG. Crystalline structure of annealed polylactic acid and its relation to processing, eXP. Polym Let. 2010;4(10):659–68.

Chow WS, Lok SK. Thermal properties of poly(lactic acid)/organo-montmorillonite nanocomposites. J Therm Anal Calorim. 2009;95(2):627–32.

Tsuji H, Tezuka Y. Stereocomplex formation between enantiomeric poly(lactic acid)s. 12. Spherulite growth of low-molecular-weight poly(lactic acid)s from the melt, Biomacromol. 2004;5:1181–6.

Rodrigues JAFR, Parra DF, Lugáo AB. Crystallization on films of PHB/PEG blends. J Therm Anal Calorim. 2005;79:379–81.

Ebadi-Dehaghani H, Barikani M, Khonakdar HA, Jafari SH, Wagenknecht U, Heinrich G. An investigation on compatibilization threshold in the interface of PP/PLA blends using rheological studies. J Vin Add Tech. 2014;. doi:10.1002/vnl.21424.

Bai F, Li F, Calhoun B, Quirk RP, Cheng SZD. Polymer Handbook. 4th ed. New York: John Wiley & Sons Inc.; 1999.

Brandrup J, Immergut EH. Polymer Hand Book. New York: Wiley; 1975.

Battegazzore D, Bocchini S, Frache A. Crystallization kinetics of poly(lactic acid)-talc composites. eXP Polym Let. 2011;5:849–58.

Labour T, Vigier G, Séguéla R, Gauthier C, Orange G, Bomal Y. Influence of the β-crystalline phase on the mechanical properties of unfilled and calcium carbonate-filled polypropylene: Ductile cracking and impact behavior. J Polym. Sci Part B-Polym Phys. 2002;40:31–42.

Qian J, Cheng G, Zhang H, Liu YX. Preparation and characterization of polypropylene/silica nanocomposites by gamma irradiation via ultrafine blend J Polym Res. 2011;18:409–17.

Scherrer P. Bestimmung der Größe und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen. 1918;2:98.

Bertoluzza A, Fagnano C. Morelli MA, Gotfardi V, Guglielmi M. Raman and Infra-Red spectra on silica gel evolving towards glass, J Non-Crystal Sol. 1982;48:1–17.

Ramez A, Occurrence M. Mineralogy of a deposit of Shampoo-clay in southern Iran. Appl Clay Sci. 1996;11:43–5.

Bahari A, Morgen P, Li ZS. Ultra-thin silicon nitride films on Si 100 studied with core level photoemission. Surf Sci. 2008;602:2315–24.

Hernandez-Torres J, Mendoza-Galvan A. Formation of NiO–SiO2 nanocomposite thin films by the sol–gel method. J. Nan crystalline solids. 2005;351:2029–35.

Fortunati E, Armentano I, Zhou Q, Puglia D, Terenzi A, Berglund LA, Kenny JM. Microstructure and nonisothermal cold crystallization of PLA composites based on silver nanoparticles and nanocrystalline cellulose. Polym Deg Stab. 2012;97:2027–36.

Lee SJ, Hahm WG, Kikutani T, Kim BC. Effects of clay and POSS nanoparticles on the quiescent and shear-induced crystallization behavior of high molecular weight poly(ethylene terephthalate). Polym Eng Sci. 2009;49:317–23.

Wan W, Yu D, Xie Y, Guo X, Zhou W, Cao J. Effects of nanoparticle treatment on the crystallization behavior and mechanical properties of polypropylene/calcium carbonate nanocomposites. J Appl Polym Sci. 2006;102:3480–8.

Lin ZD, Huang ZZ, Zhang Y, Mai KC, Zeng HM. Crystallization and melting behavior of nano-CaCO3/polypropylene composites modified by acrylic acid. J Appl Polym Sci. 2004;91:2443–53.

Yang Z, Mai K. Nonisothermal crystallization and melting behavior of β-nucleated isotactic polypropylene and polyamide 66 blends. J Appl Polym Sci. 2011;119:3566–73.

Martin O, Avérous L. Poly(lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer. 2001;42:6209–19.

Di Lorenzo ML. Crystallization behavior of poly(l-lactic acid). Eur Polym J. 2005;41:569–75.

Yew G H, Mohd Yusof A M, Mohd Ishak Z A, Ishiaku U S. Water absorption and enzymatic degradation of poly(lactic acid)/rice starch composites, Polym Deg Stab. 2005;90:488-500.

Scheirs J. Compositional and Failure Analysis of Polymers: A Practical Approach. New York: John Wiley and Sons; 2000. p. 1.

Arnal ML, Matos ME, Morales RA, Santana OO, Müller AJ. Evaluation of the fractionated crystallization of dispersed polyolefins in a polystyrene matrix. Macromol Chem Phys. 1998;199:2275–88.

Ebadi-Dehaghani H, Khonakdar HA, Barikani M, Jafari SH. Experimental and theoretical analyses of mechanical properties of PP/PLA/clay nanocomposites. Compos- Part B. 2015;69:133–44.

Acknowledgements

The work described in this paper was supported by a grant from the Iran Polymer and Petrochemical Institute (IPPI). The authors gratefully acknowledge the Research Vice Chancellor of IPPI and his co-workers for their helps and assistances.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ebadi-Dehaghani, H., Barikani, M., Khonakdar, H.A. et al. Microstructure and non-isothermal crystallization behavior of PP/PLA/clay hybrid nanocomposites. J Therm Anal Calorim 121, 1321–1332 (2015). https://doi.org/10.1007/s10973-015-4554-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4554-8