Abstract

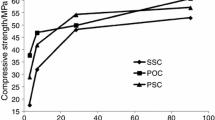

Pozzolanic cement blends were prepared by the partial substitution of ordinary Portland cement (OPC) with different percentages of burnt clay (BC), Libyan clay fired at 700 °C, of 10, 20, and 30%. The pastes were made using an initial water/solid ratio of 0.30 by mass of each cement blend and hydrated for 1, 3, 7, 28, and 90 days. The pozzolanic OPC–BC blend containing 30% BC was also admixed with 2.5 and 5% silica fume (SF) to improve the physicomechanical characteristics. The hardened pozzolanic cement pastes were subjected to compressive strength and hydration kinetics tests. The results of compressive strength indicated slightly higher values for the paste made of OPC–BC blend containing 10% BC The results of DSC and XRD studies indicated the formation and later the stabilization of calcium silicates hydrates (CSH) and calcium aluminosilicate hydrates (C3ASH4 and C2ASH8) as the main hydration products in addition to free calcium hydroxide (CH). Scanning electron microscopic (SEM) examination revealed that the pozzolanic cement pastes made of OPC–BC mixes possesses a denser structure than that of the neat OPC paste. Furthermore, the addition of SF resulted in a further densification of the microstructure of the hardened OPC–BC–SF pastes; this was reflected on the observed improvement in the compressive strength values at all ages of hydration.

Similar content being viewed by others

References

Hewlett PO. Lea’s chemistry of cement and concrete. 4th ed. London: Edward Arnold; 1998.

Cheng-Yi H, Feldman RF. Hydration reactions in Portland cement–silica fume blends. Cem Concr Res. 1985;15:585–92.

Toutanji HA, El-Korchi T. The influence of silica fume on the compressive strength of cement paste and mortar. Cem Concr Res. 1995;25(7):1591–602.

Morsy MS, Abo-El-Enein SA, Hanna GB. Microstructure and hydration characteristics of artificial pozzolana-cement pastes containing burnt kaolinite clay. Cem Concr Res. 1997;27(9):1307–12.

Sha W, Pereira GB. Differential scanning calorimetry study of ordinary Portland cement paste containing metakaolin and theoretical approach of activity. Cem Concr Res. 2001;23:455–61.

El-Shimy E, Abo-El-Enein SA, El-Didamony H, Osman TA. Physico-chemical and thermal characteristics of lime–silica fume pastes. J Therm Anal Calorim. 2000;60:549–56.

Mostafa NY, El-Hemaly SAS, Al-Wakeel EI, El-Korashy SA, Brown PW. Characterization and evaluation of the pozzolanic activity of Egyptian industrial by-products. I. Silica fume and dealuminated kaolin. Cem Concr Res. 2001;31:467–74.

Zelic J, Rusic D, Veza D, Krstulovic R. The role of silica fume in the kinetics and mechanisms during the early stage of cement hydration. Cem Concr Res. 2000;30:1655–62.

Sabir BB, Wild S, Bai J. Metakaolin and calcined clays as pozzolans for concrete: a review. Cem Concr Res. 2001;23:441–54.

Karakeci AY, Temiz H. An investigation on microstructure of cement paste containing fly ash and silica fume. Cem Concr Res. 2002;32:1131–2.

Li L, Sun H, LI C. The comparison between alkali-activated slag (Si + Ca) and metakaolin (Si + Al) cements. Cem Concr Res. 2010;40:1341–9.

Uzal B, Turanli L, Yucel H, Goncuoglu MC, Culfaz A. Pozzolanic activity of clinoptilolite: a comparative study with silica fume, fly ash and a non-zeolitic natural pozzolan. Cem Concr Res. 2010;40:398–404.

Elimbi A, Tchakoute HK, Njopwouo D. Effects of calcination temperature of kaolinite clays on the properties of geopolymer cements. Constr Build Mater. 2011;25:2805–12.

Abo-El-Enein SA, Daimon M, Ohsawa S, Kondo R. Hydration of low porosity slag–lime pastes. Cem Concr Res. 1974;4:299–312.

Kondo R, Abo-El-Enien SA, Daimon M. Kinetics and mechanisms of hydrothermal reaction of granulated blastfurnace slag. Bull Chem Soc Jpn. 1975;48:222–6.

Abo-El-Enein SA, Abbas R, Ezzat YE. Properties and durability of metakaolin blended cements. Materiales de Construccion. 2010;60(299):21–35.

Singh M, Garg M. Reactive pozzolana from Indian clays—their use in cement mortars. Cem Concr Res. 2006;36:1903–7.

Said-Mansour M, Kadri E, Kenai S, Ghrici M, Bennaceur R. Influence of calcined kaolin on mortar properties. Constr Build Mater. 2011;25:2275–82.

Pera J, Boumaza R, Ambroise J. Development of a pozzolanic pigment from red mud. Cem Concr Res. 1997;27(10):1513–22.

Mitchell DRG, Hinczak I, Day RA. Interaction of silica fume with calcium hydroxide solutions and hydrated cement pastes. Cem Concr Res. 1998;28(11):1571–84.

Rao GA. Investigations on the performance of silica fume-incorporated cement pastes and mortars. Cem Concr Res. 2003;33:1765–70.

Morsy MS, Galal AF, Abo-El-Enein SA. Effect of temperature on phase composition and microstructure of artificial pozzolana-cement pastes containing burnt kaolinite clay. Cem Concr Res. 1998;28(8):1157–63.

Klimesch DS, Ray A, Guerbois J-P. Differential scanning calorimetry evaluation of autoclaved cement based building materials made with construction and demolition waste. Thermochim Acta. 2002;389:195–8.

Cong X, Kirkpatrich RJ. Effects of the temperature and relative humidity on the structure of C-S-H gel. Cem Concr Res. 1995;25(6):1237–45.

Hidalgo A, Garcia JL, Alonso MC, Fernandez L, Andrade C. Microstructure development in mixes of calcium aluminate cement with silica fume or fly ash. J Therm Anal Calorim. 2009;96(2):335–45.

Chaipanich A, Nochaiya T. Thermal analysis and microstructure of Portland cement–fly ash–silica fume pastes. J Therm Anal Calorim. 2010;99:487–93.

Giergiczny Z. Effect of some additives on the reactions in fly ash–Ca(OH)2 system. J Therm Anal Calorim. 2004;76:747–54.

Nochaiya T, Wongkeo W, Pimraksa K, Chaipanich A. Microstructural, physical, and thermal analyses of Portland cement–fly ash–calcium hydroxide blended pastes. J Therm Anal Calorim. 2010;100:101–8.

Amer AA. Thermal analysis of hydrated fly ash–lime pastes. J Therm Anal Calorim. 1998;54:837–43.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amin, M.S., Abo-El-Enein, S.A., Abdel Rahman, A. et al. Artificial pozzolanic cement pastes containing burnt clay with and without silica fume. J Therm Anal Calorim 107, 1105–1115 (2012). https://doi.org/10.1007/s10973-011-1676-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1676-5