Abstract

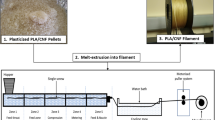

Filaments for three-dimensional printing were fabricated from composites based from biodegradable Poly(lactic Acid) (PLA) and renewable rice husk (RH). Acrylic acid (AA)-grafted PLA (PLA-g-AA) and coupling agent-treated rice husk (TRH) were incorporated to improve the properties of PLA/RH biocomposites. The biocomposite morphology, tensile properties, water absorption, and biodegradability were investigated. PLA-g-AA/TRH demonstrated superior tensile properties than PLA/RH because of the improved compatibility between the polymer and the TRH. TRH was evenly dispersed in the PLA-g-AA, brought about by ester reaction; consequently, branched and three-dimensional networks structures were generated. These PLA-g-AA/TRH biocomposites can be used as biodegradable materials or filaments for 3D printing applications because of their low cost and excellent properties.

Similar content being viewed by others

References

Obeng-Odoom F (2014) Green neoliberalism: recycling and sustainable urban development in Sekondi-Takoradi. Habitat Int 41:129–134

Panda AK, Singh RK, Mishra DK (2010) Thermolysis of waste plastics to liquid fuelA suitable method for plastic waste management and manufacture of value added products—a world prospective. Renew Sust Energ Rev 14(1):233–248

Álvarez-Chávez CR, Edwards S, Moure-Eraso R, Geiser K (2012) Sustainability of bio-based plastics: general comparative analysis and recommendations for improvement. J Clean Prod 23(1):47–56

Shih Y-F, Huang C-C (2011) Polylactic acid (PLA)/banana fiber (BF) biodegradable green composites. J Polym Res 18(6):2335–2340

Tsou CH, Lee HT, Hung WS, Wang CC, Shu CC, Suen MC, De Guzman M (2016) Synthesis and properties of antibacterial polyurethane with novel Bis(3-pyridinemethanol) silver chain extender. Polymer 85:96–105

Radjabian M, Kish MH, Mohammadi N (2012) Structure–property relationship for poly(lactic acid) (PLA) filaments: physical, thermomechanical and shape memory characterization. J Polym Res 19(6):9870

Martin O, Avérous L (2001) Poly(lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer 42(14):6209–6219

Tsou CH, Suen MC, Yao WH, Yeh JT, Wu CS, Tsou CY, Chiu SH, Chen JC, Wang RY, Lin SM, Hung WS, De Guzman M, Hu CC, Lee KR (2014) Preparation and characterization of bioplastic-based green renewable composites from tapioca with acetyl Tributyl citrate as a plasticizer. Materials 7:5617–5632

Tsou CH, Wu CS, Hung WS, De Guzmana MR, Gao C, Wang RY, Chen J, Wan N, Peng YJ, Suen MC (2019) Rendering polypropylene biocomposites antibacterial through modification with oyster shell powder. Polymer 160:265–271. https://doi.org/10.1016/j.polymer.2018.11.048

Tsou C-H, Yao W-H, Lu Y-C, Tsou C-Y, Wu C-S, Chen J, Wang RY, Su C, Hung W-S, De Guzman M, Suen M-C (2017) Antibacterial property and cytotoxicity of a poly(lactic acid)/nanosilver-doped multiwall carbon nanotube Nanocomposite. Polymers 9:100

Li HZ, Chen SC, Wang YZ (2014) Thermoplastic PVA/PLA blends with improved processability and hydrophobicity. Ind Eng Chem Res 53(44):17355–17361

Mahieu A, Terrié C, Agoulon A, Leblanc N, Youssef B (2013) Thermoplastic starch and poly(ε-caprolactone) blends: morphology and mechanical properties as a function of relative humidity. J Polym Res 20:229

Wu C-S, Liao H-T, Tsou C-H (2018) Polyester-based green renewable eco-composites by solar energy tube processing: characterization and assessment of properties. J Polym Res 25:240

Müller P, Bere J, Fekete E, Móczó J, Pukánszky B (2016) Interactions, structure and properties in PLA/plasticized starch blends. Polymer 103:9–18

Tsou CH, Yao WH, Hung WS, Suen MC, De Guzman M, Chen J, Tsou CY, Wang RY, Chen JC, Wu CS (2018) Innovative plasma process of grafting methyl diallyl ammonium salt onto polypropylene to impart antibacterial and hydrophilic surface properties. Ind Eng Chem Res 57(7):2537–2545

Qian S, Zhang H, Yao W, Sheng K (2018) Effects of bamboo cellulose nanowhisker content on the morphology, crystallization, mechanical, and thermal properties of PLA matrix biocomposites. Compos Part B 133:203–209

Raquez JM, Habibi Y, Murariu M, Dubois P (2013) Polylactide (PLA)-based nanocomposites. Prog Polym Sci 38(10–11):1504–1542

Tan JP, Jahim JM, Wu TY, Harun S, Kim BH, Mohammad AW (2014). Ind Eng Chem Res 53(42):16123–16134

Ding L, Zou B, Shen L, Zhao C, Wang Z, Guo Y, Wang X, Liu Y (2014) A simple route for consecutive production of activated carbon and liquid compound fertilizer from rice husk. Colloid Surf A 446:90–96

Anda M, Shamshuddin J, Fauziah CI (2013) Increasing negative charge and nutrient contents of a highly weathered soil using basalt and rice husk to promote cocoa growth under field conditions. Soil Tillage Res 132:1–11

Zhang D, Chi B, Li B, Gao Z, Du Y, Guo J, Wei J (2016) Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth Met 217:79–86

Yussuf AA, Massoumi I, Hassan A (2010) Comparison of Polylactic acid/Kenaf and Polylactic acid/rise husk composites: the influence of the natural fibers on the mechanical, thermal and biodegradability properties. J Polym Environ 18:422–429

Tsou CH, Hung WS, Wu CS, Chen JC, Huang CY, Chiu SH, Tsou CY, Yao WH, Lin SM, Chu CK, Hu CC, Lee KR, Suen MC (2014) New composition of maleic-anhydride-grafted poly(lactic acid)/rice husk with methylenediphenyl diisocyanate 20:446–451

Nourbakhsh A, Baghlani FF, Ashori A (2011) Nano-SiO2 filled rice husk/polypropylene composites: Physico-mechanical properties. Ind Crop Prod 33(1):183–187

Panthapulakkal S, Sain M, Law S (2005) Effect of coupling agents on rice-husk-filled HDPE extruded profiles. Polym Int 54(1):137–142

Wu CS, Liao HT (2017) Polyester-based green composites for three-dimensional printing strips: preparation, characterization and antibacterial properties. Polym Bull 74(6):2277–2295

Wu CS, Liao HT (2017) Interface design of environmentally friendly carbon nanotube-filled polyester composites: fabrication, characterisation, functionality and application. Express Polym Lett 11(3):187–198

Nourbakhsh A, Ashori A, Tabrizi AK (2014). Compos Part B 56:279–283

Shih YF (2007). Mater Sci Eng A 445–446:289–295

Jandas PJ, Mohanty S, Nayak SK (2013) Mechanical properties of surface-treated banana fiber/polylactic acid biocomposites: A comparative study of theoretical and experimental values. J Appl Polym Sci 127(5):4027–4038

Tran TPT, Bénézet JC, Bergeret A (2014) Rice and Einkorn wheat husks reinforced poly(lactic acid) (PLA) biocomposites: Effects of alkaline and silane surface treatments of husks. Ind Crop Prod 58:111–124

Saffar A, Carreau PJ, Kamal MR, Ajji A (2014) Hydrophilic modification of polypropylene microporous membranes by grafting TiO2 nanoparticles with acrylic acid groups on the surface. Polymer 55(23):6069–6075

Ayswarya EP, Vidya FKF, Renju VS, Thachil ET (2012). Mater Des 41:1–7

Mittal V, Akhtar T, Luckachan G, Matsko N (2015) PLA, TPS and PCL binary and ternary blends: structural characterization and time-dependent morphological changes. Colloid Polym Sci 293(2):573–585

Wu CS (2012). Polym Degrad Stab 97:64–71

Zhao H, Chen Q, Zhang S (2012). Microporous Mesoporous Mater 155:240–244

Aliotta L, Cinelli P, Coltelli MB, Righetti MC, Gazzano M, Lazzeri A (2017). Eur Polym J 93:822–832

Rosa SML, Rehman N, de Miranda MIG, Nachtigall SMB, Bica CID (2012) Chlorine-free extraction of cellulose from rice husk and whisker isolation. Carbohydr Polym 87(2):1131–1138

Danyadi L, Janecska T, Szabo Z, Nagy G, Moczo J, Pukanszky BW (2007) Wood flour filled PP composites: compatibilization and adhesion. Compos Sci Technol 67(13):2838–2846

Bajpai PK, Singh I, Madaan J (2013) Tribological behavior of natural fiber reinforced PLA composites. Wear 297(1–2):829–840

Prasitnok K (2016) A coarse-grained model for polylactide: glass transition temperature and conformational properties. J Polym Res 23(7):1–9

Gamon G, Evon P, Rigal L (2013) Twin-screw extrusion impact on natural fibre morphology and material properties in poly(lactic acid) based biocomposites. Ind Crop Prod 46:173–185

Dong Y, Ghataura A, Takagi H, Haroosh HJ, Nakagaito AN, Lau KT (2014) Polylactic acid (PLA) biocomposites reinforced with coir fibres: Evaluation of mechanical performance and multifunctional properties. Compos Part A 63:76–84

Tsou C-H, Gao C, De Guzman M, Wu D-Y, Hung W-S, Yuan L, Suen M-C, Yeh J-t (2018) Preparation and characterization of poly(lactic acid) with adipate ester added as a plasticizer. Polym Polym Compos 26:446–453. https://doi.org/10.1177/0967391118809210

Tsou CY, Wu CL, Tsou CH, Chiu SH, Suen MC, Hung WS (2015) Biodegradable composition of poly(lactic acid) from renewable wood flour. Polym Sci Ser B 57:473–480

Acknowledgements

The authors would like to thank the National Science Council (Taipei City, Taiwan, R.O.C.) for the financial support (MOST 103-2622-E-244 -001 -CC3) and Wuliangye Group Co. Ltd. The authors also express their appreciation to the National Natural Science Foundation of China, Apex Nanotek Co. Ltd., the Ratchadapisek Sompote Fund for Postoctoral Fellowship (Chulalongkon University), the Sichuan Province Science and Technology Support Program (19CXRC0081), the Zigong City Science and Technology office (2017XC16).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, CS., Tsou, CH. Fabrication, characterization, and application of biocomposites from poly(lactic acid) with renewable rice husk as reinforcement. J Polym Res 26, 44 (2019). https://doi.org/10.1007/s10965-019-1710-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1710-z