Abstract

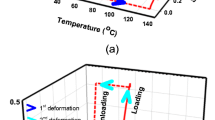

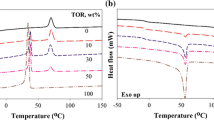

PLA and TPU were melt-blended to form shape memory bio-based blends in order to improve the shape memory effect of PLA. The shape memory behaviors of PLA/TPU blends predeformed under three different predeformation temperatures (25, 80, 120 °C) were investigated at various recovery temperatures. At the predeformation temperature of 25 °C, the addition of TPU significantly increased the shape recovery ratio of PLA up to 93.5 ± 0.4 % at 160 °C for the PLA/TPU (50/50) blends. With the increase of predeformation temperatures, the shape fixing ability enhanced, but the ability of shape recovery decreased. In order to consider both fixing and recovery ratios together, an additional denotation of shape memory index to couple both ratios by the multiplication of fixing ratio (Rf) and recovery ratio (Rr) was also considered. The sharp increases in the shape memory index curves against recovery temperatures for blends predeformed near the glass transition temperature of PLA were observed in comparison with the gradual, and earliest or latest, increases in the shape recovery curves for those predeformed at room temperature or high temperature. The recovery stress peak temperatures largely corresponded to the predeformation temperatures and increased with increasing the predeformation temperatures, indicating a unique “memory” effect for this type of bio-based blends in terms of recovery stress.

Similar content being viewed by others

References

Kweon DK, Cha DS, Park HJ, Lim ST (2000) J Appl Polym Sci 78:986–993

Ray SS, Okamoto M (2003) Macromol Rapid Commun 24:815–840

Ratna D, Karger-Kocsis J (2008) J Mater Sci 43:254–269

Meng Q, Hu J (2009) Compos Part A 40:1661–1672

Leng J, Lan X, Liu Y, Du S (2011) Prog Mater Sci 56:1077–1135

Chang YW, Eoma JP, Kim JG, Kim HT, Kim DK (2010) J Ind Eng Chem 16:256–260

Zhang Y, Wang Q, Wang C, Wang T (2011) J Mater Chem 21:9073–9078

Schoener CA, Weyand CB, Murthy R, Grunlan MA (2010) J Mater Chem 20:1787–1793

Huang WM, Zhao Y, Wang CC, Ding Z, Purnawali H, Tang C, Zhang JL (2012) J Polym Res 19:9952–9985

Mather PT, Liu C, Campo CJ (2007) U.S. Patent No. 7371799:1–11

Liu C, Mather PT (2003) ANTEC 2:1962–1966

Arnoult OB, Mather PT (2007) ANTEC 2:839–844

Li SC, Lu LN, Zeng W (2009) J Appl Polym Sci 112:3341–3346

Weiss RA, Izzo E, Mandelbaum S (2008) Macromolecules 41:2978–2980

Lin GM, Sui GX, Yang R (2012) J Appl Polym Sci 126:350–357

Zhang W, Chen L, Zhang Y (2009) Polymer 50:1311–1315

Fei F, Lin Y (2011) J Appl Polym Sci 119:2778–2783

Gupta B, Revagade N, Hilborn J (2007) Prog Polym Sci 32:455–482

Hong H, Wei J, Yuan Y, Chen FP, Wang J, Qu X, Liu CS (2011) J Appl Polym Sci 121:855–861

Li Y, Shimizu H (2007) Macromol Biosci 7:921–928

Gall K, Yakacki CM, Liu Y, Shandas R, Willett N, Anseth KS (2005) J Biomed Mater Res A 73:339–348

Wen X, Lin Y, Han C, Zhang K, Ran X, Li Y, Dong L (2009) J Appl Polym Sci 114:3379–3388

Miaudet P, Derré A, Maugey M, Zakri C, Piccione PM, Inoubli R, Poulin P (2007) Science 23:1294–1296

Amirian M, Chakoli AN, Sui J, Cai W (2012) J Polym Res 19:9777–9786

Acknowledgments

The authors are grateful for Mr. Ping-Hsiu Huang for helping the manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lai, SM., Lan, YC. Shape memory properties of melt-blended polylactic acid (PLA)/thermoplastic polyurethane (TPU) bio-based blends. J Polym Res 20, 140 (2013). https://doi.org/10.1007/s10965-013-0140-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0140-6