Abstract

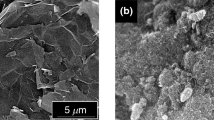

The elongational flow properties of TiO2 nanoparticle/polypropylene (PP) nanocomposite fibers were studied via melt spinning. The diameter, tension, and flow rate of fibers were directly measured and used to calculate the apparent elongational viscosity and apparent elongational strain rate using Cogswell’s theory. Thermal gravimetric analysis (TGA) was used to demonstrate that the TiO2 nanoparticles improved the thermal stability of the PP fibers. With a 1–3 wt % loading of the TiO2 nanoparticles, the PP fiber decomposition temperatures ranged from 338 °C for the pristine polymer to 342, 349, and 367 °C; the decomposition was accompamied by an initial 95 wt % weight loss. In addition, the well-distributed morphology of the TiO2 nanoparticles on the side surface of the PP matrix was observed using atomic force microscopy (AFM). At 1 wt % loading of the TiO2 nanoparticles, the surfaces of the PP nanofibers contained mono-disperse nanoparticles with sizes of 20–50 nm. Furthermore, the TiO2 nanoparticle/PP nanocomposite fibers were shown to be thermally stable and are suitable for application as an antibacterial polymer.

Similar content being viewed by others

References

Pavlidoua S, Papaspyrides CD (2008) Prog Polym Sci 33:1119–1198. doi:10.1016/j.progpolymsci.2008.07.008

Kubacka A, Serrano C, Ferrer M, Lunsdorf H, Bielecki P, Cerrada ML, Fernandez-Garcia M (2007) Nano Lett 7:2529–2534. doi:10.1021/nl0709569

Kagan CR, Mitzi DB, Dimitrakopoulos CD (1999) Science 286:945–947. doi:10.1126/science.286.5441.945

Eckle M, Decher G (2001) Nano Lett 1:45–49. doi:10.1021/nl005514a

Choy JH, Kwak SY, Jeong YJ, Park JS (2000) Angew Chem Int Ed 39:4041–4045. doi:10.1002/1521-3773(20001117)39:22<4041::AID-ANIE4041>3.0.CO;2-C

Cristofaro AD, Violante A (2001) Appl Clay Sci 19:59–67. doi:10.1016/S0169-1317(01)00047-3

Chopra KL (1969) Thin film phenomena. McGraw-Hill, New York

Hsu YG, Lin KH (2001) J Polym Res 8:69–76. doi:10.1007/s10965-006-0136-6

Jakob M, Levanon H, Kamat PV (2003) Nano Lett 3:353–358. doi:10.1021/nl0340071

Shi SL, Zhang LZ, Li JS (2009) J Polym Res 16:395–399. doi:10.1007/s10965-008-9241-z

Chiu FC, Chu PH (2006) J Polym Res 13:73–78. doi:10.1007/s10965-005-9009-7

Linsebigler AL, Lu G, Yates JT Jr (1995) Chem Rev 95:735–758. doi:10.1021/cr00035a013

Karger-Kocsis J (1999) Polypropylene an a-z reference. Kluwer Academic, London

Kotek J, Kelnar I, Studenovsky M, Baldrian J (2005) Polymer 46:4876–4881. doi:10.1016/j.polymer.2005.02.119

Schimanski T, Peijs T, Lemstra PJ, Loos J (2004) Macromolecules 37:1810–1815. doi:10.1021/ma034949s

Thio YS, Argon AS, Cohen RE (2004) Polymer 45:3139–3147. doi:10.1016/j.polymer.2004.02.064

Greener J, Evans JRG (1997) J Eur Ceram Soc 17:1173–1183. doi:10.1016/S0955-2219(96)00227-0

Koizumi T, Usui S (1999) J Appl Polym Sci 71:2381–2384. doi:10.1002/(SICI)1097-4628(19990404)71:14<2381::AID-APP9>3.0.CO;2-6

Cogswell FN (1969) Rheol Acta 8:187–194. doi:10.1007/BF01984657

Cogswell FN (1972) Polym Eng Sci 12:64–73. doi:10.1002/pen.760120111

Ku TH, Lin CA (2005) J Polym Res 12:23–29. doi:10.1007/s10965-004-0985-9

Yeo SY, Jeong SH (2003) Polym Internat 52:1053–1057. doi:10.1002/pi.1215

Wunderlich B (1990) Thermal Analysis. Academic Press, New York, p 418

Tang J, Redl F, Zhu Y, Siegrist T, Brus LE, Steigerwald ML (2005) Nano Lett 5:543–548. doi:10.1021/nl047992h

Kumar AP, Depan D, Tomer NS, Singh RP (2009) Prog Polym Sci 34:479–515. doi:10.1016/j.progpolymsci.2009.01.002

Alexandre M, Dubois P (2000) Mater Sci Eng 28:1–63. doi:10.1016/S0927-796X(00)00012-7

Ray SS, Okamoto M (2003) Prog Polym Sci 28:1539–1641. doi:10.1016/j.progpolymsci.2003.08.002

Acknowledgement

We acknowledge financial support from the Ministry of Economic Affairs and the National Science Council (NSC) of Taiwan. We thank Professor Jiang-Jen Lin at National Taiwan University for helpful discussions.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chiu, CW., Lin, CA. & Hong, PD. Melt-spinning and thermal stability behavior of TiO2 nanoparticle/polypropylene nanocomposite fibers. J Polym Res 18, 367–372 (2011). https://doi.org/10.1007/s10965-010-9426-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9426-0