Abstract

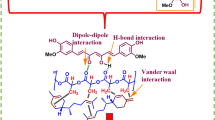

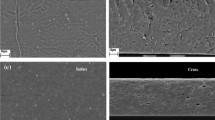

The development of active packaging for food applications have been increasingly favorable in publicity, industry, and research field, by attributing to the bio-safety in nature and promising antimicrobial property in preserving food product. In this study, polybutylene succinate (PBS) was used as the main polymeric material for preparing active film and incorporated with different active agents, i.e. thymol, kesum, and curry via solvent casting method. The produced active films were characterized through advanced analysis techniques. From morphology examination, kesum filled PBS film showed well-integrated film structure, whereas the thymol and curry filled PBS films presented poor adhesion features comparing to pure PBS film. Also, the functional chemistry analysis revealed the presence of functional groups from active substances, indicating the successful incorporation of active agent in PBS film. Furthermore, the thermal analysis proved the thymol filled PBS film was with the greatest heat resistance due to its solidity structure. In terms of crystallinity, the kesum filled PBS film exhibited the highest crystallinity among the film samples, by associating to its great nucleating effect. Additionally, the films containing 10% kesum and thymol respectively showed zone of inhibition against S. aureus. However, the films tested on chicken fillet samples showed insignificant inhibitory effect on foodborne microbes. Nonetheless, the quality of chicken fillet covered with active PBS films had been improved with color attributes at 15% loading of active agent. Therefore, the active films produced in this work have potential to be utilized in the future for food packaging application.

Similar content being viewed by others

References

Ahmed J, Mulla M, Jacob H, Luciano G, Bini TB, Almusallam A (2019) Polylactide/poly (ε-caprolactone)/zinc oxide/clove essential oil composite antimicrobial films for scrambled egg packaging. Food Packag Shelf Life 21:100355. https://doi.org/10.1016/j.fpsl.2019.100355

Mohamad N, Mazlan MM, Tawakkal ISMA, Talib RA, Kian LK, Fouad H, Jawaid M (2020) Development of active agents filled polylactic acid films for food packaging application. Int J Biol Macromol 163:1451–1457. https://doi.org/10.1016/j.ijbiomac.2020.07.209

Sivakanthan S, Rajendran S, Gamage A, Madhujith T, Mani S (2020) Antioxidant and antimicrobial applications of biopolymers: a review. Food Res Int 136:109327. https://doi.org/10.1016/j.foodres.2020.109327

Llana-Ruíz-Cabello M, Puerto M, Pichardo S, Jiménez-Morillo NT, Bermúdez JM, Aucejo S, González-Pérez JA (2019) Preservation of phytosterol and PUFA during ready-to-eat lettuce shelf-life in active bio-package. Food Packag Shelf Life 22:100410. https://doi.org/10.1016/j.fpsl.2019.100410

Chi H, Song S, Luo M, Zhang C, Li W, Li L, Qin Y (2019) Effect of PLA nanocomposite films containing bergamot essential oil, TiO2 nanoparticles, and Ag nanoparticles on shelf life of mangoes. Sci Hortic 249:192–198. https://doi.org/10.1016/j.scienta.2019.01.059

Suwanamornlert P, Kerddonfag N, Sane A, Chinsirikul W, Zhou W, Chonhenchob V (2020) Poly (lactic acid)/poly (butylene-succinate-co-adipate) (PLA/PBSA) blend films containing thymol as alternative to synthetic preservatives for active packaging of bread. Food Packag Shelf Life 25:100515. https://doi.org/10.1016/j.fpsl.2020.100515

Shavisi N, Khanjari A, Basti AA, Misaghi A, Shahbazi Y (2017) Effect of PLA films containing propolis ethanolic extract, cellulose nanoparticle and ziziphora clinopodioides essential oil on chemical, microbial and sensory properties of minced beef. Meat Sci 124:95–104. https://doi.org/10.1016/j.meatsci.2016.10.015

Petchwattana N, Naknaen P (2015) Utilization of thymol as an antimicrobial agent for biodegradable poly (butylene succinate). Mater Chem Phys 163:369–375. https://doi.org/10.1016/j.matchemphys.2015.07.052

Wiburanawong S, Petchwattana N, Covavisaruch S (2014) Carvacrol as an antimicrobial agent for poly (butylene succinate): tensile properties and antimicrobial activity observations. Adv Mater Res 931:111–115

Wang LF, Rhim JW (2016) Grapefruit seed extract incorporated antimicrobial LDPE and PLA films: effect of type of polymer matrix. LWT-Food Sci Technol 74:338–345. https://doi.org/10.1016/j.lwt.2016.07.066

Wrona M, Cran MJ, Nerín C, Bigger SW (2017) Development and characterisation of HPMC films containing PLA nanoparticles loaded with green tea extract for food packaging applications. Carbohydr Polym 156:108–117. https://doi.org/10.1016/j.carbpol.2016.08.094

Khodayari M, Basti AA, Khanjari A, Misaghi A, Kamkar A, Shotorbani PM, Hamedi H (2019) Effect of poly (lactic acid) films incorporated with different concentrations of tanacetum balsamita essential oil, propolis ethanolic extract and cellulose nanocrystals on shelf life extension of vacuum-packed cooked sausages. Food Packag Shelf Life 19:200–209. https://doi.org/10.1016/j.fpsl.2018.11.009

Javaherzadeh R, Bafroee AT, Kanjari A (2020) Preservation effect of polylophium involucratum essential oil incorporated poly lactic acid/nanochitosan composite film on shelf life and sensory properties of chicken fillets at refrigeration temperature. LWT-Food Sci Technol 118:108783. https://doi.org/10.1016/j.lwt.2019.108783

Takma DK, Korel F (2019) Active packaging films as a carrier of black cumin essential oil: development and effect on quality and shelf-life of chicken breast meat. Food Packag Shelf Life 19:210–217. https://doi.org/10.1016/j.fpsl.2018.11.002

Arfat YA, Ahmed J, Ejaz M, Mullah M (2018) Polylactide/graphene oxide nanosheets/clove essential oil composite films for potential food packaging applications. Int J Biol Macromol 107:194–203. https://doi.org/10.1016/j.ijbiomac.2017.08.156

Otoni CG, de Moura MR, Aouada FA, Camilloto GP, Cruz RS, Lorevice MV, de Soares FFN, Mattoso LH (2014) Antimicrobial and physical-mechanical properties of pectin/papaya puree/cinnamaldehyde nanoemulsion edible composite films. Food Hydrocoll 41:188–194. https://doi.org/10.1016/j.foodhyd.2014.04.013

Santagata G, Valerio F, Cimmino A, Dal Poggetto G, Masi M, Di Biase M, Malinconico M, Lavermicocca P, Evidente A (2017) Chemico-physical and antifungal properties of poly (butylene succinate)/cavoxin blend: study of a novel bioactive polymeric based system. Eur Polym J 94:230–247. https://doi.org/10.1016/j.eurpolymj.2017.07.004

Chia SR, Foo SP, Hew YS, Loh YJ, Devadas VV, Chew KW, Show PL (2020) Extraction of phenolic compounds from fresh and wilt kesum plant using liquid biphasic flotation. Sep Purif Technol 242:116831. https://doi.org/10.1016/j.seppur.2020.116831

Wen D, Liu Y, Yu Q (2020) Metabolomic approach to measuring quality of chilled chicken meat during storage. Poult Sci 99:2543–2554. https://doi.org/10.1016/j.psj.2019.11.070

Noori S, Zeynali F, Almasi H (2018) Antimicrobial and antioxidant efficiency of nanoemulsion-based edible coating containing ginger (zingiber officinale) essential oil and its effect on safety and quality attributes of chicken breast fillets. Food Control 84:312–320. https://doi.org/10.1016/j.foodcont.2017.08.015

Linlin L, Hualin W, Minmin C, Suwei J, Junfeng C, Xingjiang L, Mingzhu Z, Shaotong J (2020) Gelatin/zein fiber mats encapsulated with resveratrol: Kinetics, antibacterial activity and application for pork preservation. Food Hydrocoll 101:105577. https://doi.org/10.1016/j.foodhyd.2019.105577

Ramos M, Beltran A, Fortunati E, Peltzer MA, Cristofaro F, Visai L, Valente AJ, Jiménez A, Kenny JM, Garrigós MC (2020) Controlled release of thymol from poly(lactic acid)-based silver nanocomposite films with antibacterial and antioxidant activity. Antioxidants 9:395. https://doi.org/10.3390/antiox9050395

Lule Z, Ju H, Kim J (2018) Effect of surface-modified Al2O3 on the thermomechanical properties of polybutylene succinate/Al2O3 composites. Ceram Int 44:13530–13537. https://doi.org/10.1016/j.ceramint.2018.04.184

Zhang M, Li Y, Wang L, Li S (2020) Compatibility and mechanical properties of gelatin-filled polybutylene succinate composites. J Appl Polym Sci 137:48881. https://doi.org/10.1002/app.48881

Altan A, Aytac Z, Uyar T (2018) Carvacrol loaded electrospun fibrous films from zein and poly (lactic acid) for active food packaging. Food Hydrocoll 81:48–59. https://doi.org/10.1016/j.foodhyd.2018.02.028

Abidin ASZ, Yusoh K, Jamari SS, Abdullah AH, Ismail Z (2018) Surface functionalization of graphene oxide with octadecylamine for improved thermal and mechanical properties in polybutylene succinate nanocomposite. Polym Bull 75:3499–3522. https://doi.org/10.1007/s00289-017-2217-6

Huang J, Lu X, Zhang N, Yang L, Yan M, Liu H, Qu J (2014) Study on the properties of nano-TiO2/polybutylene succinate composites prepared by vane extruder. Polym Compos 35:53–59. https://doi.org/10.1002/pc.22633

Zhang X, Wang X (2018) Polybutylene succinate/cellulose nanocrystals: role of phthalic anhydride in squeeze oriented bionanocomposites. Carbohydr Polym 196:254–261. https://doi.org/10.1016/j.carbpol.2018.04.124

Arrieta MP, López J, Ferrándiz S, Peltzer MA (2013) Characterization of PLA-limonene blends for food packaging applications. Polym Test 32:760–768. https://doi.org/10.1016/j.polymertesting.2013.03.016

Qin Y, Li W, Liu D, Yuan M, Li L (2017) Development of active packaging film made from poly (lactic acid) incorporated essential oil. Prog Org Coat 103:76–82. https://doi.org/10.1016/j.porgcoat.2016.10.017

Mizuno S, Maeda T, Kanemura C, Hotta A (2015) Biodegradability, reprocessability, and mechanical properties of polybutylene succinate (PBS) photografted by hydrophilic or hydrophobic membranes. Polym Degrad Stabil 117:58–65. https://doi.org/10.1016/j.polymdegradstab.2015.03.015

Jiang J, Gong L, Dong Q, Kang Y, Osako K, Li L (2020) Characterization of PLA-P3, 4HB active film incorporated with essential oil: application in peach preservation. Food Chem 313:126134. https://doi.org/10.1016/j.foodchem.2019.126134

Milovanovic S, Hollermann G, Errenst C, Pajnik J, Frerich S, Kroll S, Ivanovic J (2018) Supercritical CO2 impregnation of PLA/PCL films with natural substances for bacterial growth control in food packaging. Food Res Int 107:486–495. https://doi.org/10.1016/j.foodres.2018.02.065

Villegas C, Torres A, Rios M, Rojas A, Romero J, de Dicastillo CL, Guarda A (2017) Supercritical impregnation of cinnamaldehyde into polylactic acid as a route to develop antibacterial food packaging materials. Food Res Int 99:650–659. https://doi.org/10.1016/j.foodres.2017.06.031

Carbonell-Verdu A, Garcia-Garcia D, Dominici F, Torre L, Sanchez-Nacher L, Balart R (2017) PLA films with improved flexibility properties by using maleinized cottonseed oil. Eur Polym J 91:248–259. https://doi.org/10.1016/j.eurpolymj.2017.04.013

Zhao Y, Qu J, Feng Y, Wu Z, Chen F, Tang H (2012) Mechanical and thermal properties of epoxidized soybean oil plasticized polybutylene succinate blends. Polym Adv Technol 23:632–638. https://doi.org/10.1002/pat.1937

Ramos M, Jiménez A, Peltzer M, Garrigós MC (2014) Development of novel nano-biocomposite antioxidant films based on poly (lactic acid) and thymol for active packaging. Food Chem 162:149–155. https://doi.org/10.1016/j.foodchem.2014.04.026

Acknowledgements

The authors would like to thank Prof. Noriham and Dr. Nurain for providing kesum and curry essential oil for this study.

Funding

The authors thankful to Newton-Ungku Omar Fund (Vot no: 6300873) for supporting this work.

Author information

Authors and Affiliations

Contributions

Conceptualization: ISMAT, RAT; Methodology: NM, MMM, LKK; Formal analysis and investigation: NM, MMM, LKK; Resources: RAT; Data curation: NM, MMM, LKK; Writing-original draft preparation: NM, LKK; Writing-review and editing: NM, LKK, ISMAT; Supervision: ISMAT, MJ; Project administration: ISMAT, MJ; Funding acquisition: MJ.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Consent for Publication

All authors have read and agreed to the published version of the manuscript for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohamad, N., Mazlan, M.M., Tawakkal, I.S.M.A. et al. Characterization of Active Polybutylene Succinate Films Filled Essential Oils for Food Packaging Application. J Polym Environ 30, 585–596 (2022). https://doi.org/10.1007/s10924-021-02198-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02198-z