Abstract

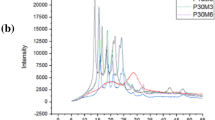

Compositions of wood-polypropylene composites (WPCs) are prepared through melt compounding followed by injection moulding. WPCs are formulated for eight compositions with a different weight ratio of wood, virgin or recycled polypropylene and coupling agent. WPCs compositions are compared in terms of Melt Flow Index, Tensile, FESEM images, Flexural and crystallinity index for same operating variable conditions. From the results, recycled polypropylene based WPCs are superior in comparison to virgin polypropylene based WPCs. With the addition of 5 % coupling agent in recycled polypropylene-based composites for 45:50 composition, tensile and flexural values of WPCs are higher in comparison to all composition and neat virgin or recycled polypropylene. This work stands for the utilization of waste wood with recycled plastic for replacement of wood and virgin plastic.

Similar content being viewed by others

References

Kengkhetkit N, Amornsakchai T (2014) A new approach to ‘‘Greening’’ plastic composites using mango apple leaf waste for performance and cost effectiveness. Mater Des 55(2014):292–299

Migneaulta S, Koubaab A, Perrec P, Riedl B (2015) Effects of wood fiber surface chemistry on strength of wood–plastic composites. Appl Surf Sci 343(2015):11–18

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15(1):25–33

Tran LQN, Fuentes CA, Dupont Gillain C, Van Vuure AW, Verpoest I (2013) Understanding the interfacial compatibility and adhesion of natural coir fibre thermoplastic composites. Compos Sci Technol 81:23–30

Gozdecki C, Wilczynski A, Kociszewski M, Zajchowski S (2015) Properties of wood–plastic composites made of milled particleboard and polypropylene. Eur J Wood Prod 73:87–95

Pelaez-Samaniego MR, Yadama V, Lowell E, Amidon TE, Chaffee TL (2013) 2013) Hot water extracted wood fiber for production of wood plastic composites (WPCs. Holzforschung 67(2):193–200

Migneault S, Koubaa A, Perre P (2014) Effect of fiber origin, proportion, and chemical composition on the mechanical and physical properties of wood-plastic composites. J Wood Chem Technol 34(2014):241–261

Li Yali (2012) Effect of coupling agent concentration Fiber content, and Size on mechanical properties of Wood/HDPE Composites. Int J Polym Mater Polym Biomater 61(11):882–890

Binhussain MA, El-Tonsy MM (2013) Palm leave and plastic waste wood composite for out-door structures. Constr Build Mater 47(2013):1431–1435

Winandy J.E., Stark N.M., Clemons C.M. (2004) 5th Global Wood and Natural fiber Composites Symposium. In: Kassel (Germany); April 27–28, 2004

Kuo P-Y, Wang S-Y, Chen J-H, Hsueh H-C, Tsai M-J (2009) Effects of material compositions on the mechanical properties of wood–plastic composites manufactured by injection molding. Mater Des 30(9):3489–3496

Nourbakhsh A, Ashori A (2010) Wood plastic composites from agro-waste materials: analysis of mechanical properties. Bioresour Technol 101:2525–2528

Yeh S-K, Gupta RK (2008) Improved wood–plastic composites through better Processing. Compos Part A 39:1694–1699

Pelaez-Samaniego MR, Yadama V, Lowell E, Espinoza-Herrera R (2013) A review of wood thermal pretreatments to improve wood composite properties. Wood Sci Technol 47:1285–1319

ASTM International (ASTM D 1238-04c) (2008) Standard test method for melt flow rates of thermoplastics by extrusion plastometer. In: Annual book of ASTM standards international, vol 08, no 01. West Conshohocken, p 277e90

ASTM International (ASTM D 638-02a) (2003) Standard test method for tensile properties of plastics. In: Annual book of ASTM standards, vol 08, no 01. West Conshohocken, PA, p 46e59

ASTM International (ASTM D 790-2007) (2008) Standard test method for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. In: Annual book of ASTM standards, vol 08, no 01. West Conshohocken, PA, p 151e61

Ruland W (1961) X-ray determination of crystallinity and diffuse disorder scattering. Acta Cryst 14:1180–1185

Park S, Baker JO, Himme ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:10

Kazayawoko M, Balatinecz JJ, Matuana LM (1999) surface modification and adhesion mechanisms in woodfiber-polypropylene composites. J Mater Sci 34(1999):6189–6199

Leu S-Y, Yang T-H, Lo S-F, Yang T-H (2012) Optimized material composition to improve the physical and mechanical properties of extruded wood–plastic composites (WPCs). Constr Build Mater 29(2012):120–127

Bledzki AK, Faruk O (2003) Wood fibre reinforced polypropylene composites: effect of fibre geometry and coupling agent on physico-mechanical properties. Appl Compos Mater 10:365–379

Chen HC, Chen TY, Hsu CH (2006) Effects of wood particle size and mixing ratios of HDPE on the properties of the composites. Holz als Roh-und Werkst 64:172–177

Ndiaye D, Matuana LM, Morlat-Therias S, Vidal L, Tidjani A, Gardette JL (2011) Thermal and mechanical properties of polypropylene/Wood-flour composites. J Appl Polym Sci 119:3321–3328

Acknowledgments

Mr.S.B.Yadaw, Scientist “G”, DMSRDE Kanpur, is providing a valuable guidance and resources for this research work. Defence Material & Stores Research& Development Establishment (DMSRDE) Kanpur and MNNIT Allahabad are utilised for the experimentations for grant no. 2349/med/f – pf/2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haq, S., Srivastava, R. Wood Polypropylene (PP) Composites Manufactured by Mango Wood Waste with Virgin or Recycled PP: Mechanical, Morphology, Melt Flow Index and Crystalline Behaviour. J Polym Environ 25, 640–648 (2017). https://doi.org/10.1007/s10924-016-0845-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0845-9