Abstracts

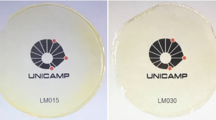

Transparent films of chitosan (CH), carboxymethyl chitosan (CMCH), and their blends were prepared using water or acetic acid as solvent and glycerol as plasticizer. Scanning electron microscopy micrographs of cross-section of the films indicated a multilayer structure for CH film and a compact and continuous one for CMCH film. In both solvent systems, increasing of concentration of plasticizer resulted in decreasing of tensile strength (TS) and increasing of elongation at break (% ε b ) of CMCH films. Moreover, CMCH films exhibited water vapor and oxygen barrier properties in the range of the values accepted for food packaging films (0.59–0.89 × 10−14 kg/s m Pa and 0.8–3.1 × 10−3 ccO2/m day atm). Although the barrier properties of CMCH films were comparable with that of CH films, CH film had significantly higher TS and % ε b . Blending of CMCH with CH (75 and 25 %, respectively) significantly enhanced the TS and % ε b of the obtained film compared to CMCH films (2.1 and 1.7 times, respectively). The water vapor and oxygen permeabilities (1.25 × 10−14 kg/s m Pa and 3.4 × 10−3 ccO2/m day atm, respectively) were still comparable with films of CH and CMCH.

Similar content being viewed by others

Abbreviations

- CMCH:

-

Carboxymethyl chitosan

- CH:

-

Chitosan

- WVP:

-

Water vapor permeability

- TS:

-

Tensile strength

- FTIR:

-

Fourier transform infrared

- SEM:

-

Scanning electron microscopy

- εb :

-

Elongation at break

References

Lee DW, Lim H, Vhong HN, Shim WS (2009) Advances in chitosan material and its hybrid derivatives: a review. Biomaterials 1:10–20

Wongpanit P, Sanchavanakit N, Pavasant P, Supaphol P, Tokura S, Rujiravanit R (2005) Preparation and characterization of microwave-treated carboxymethyl chitin and carboxymethyl chitosan films for potential use in wound care application. Macromol Bio Sci 5(10):1001–1101

Zamani A, Henriksson D, Taherzadeh J (2010) A new foaming technique for production of superabsorbents from carboxymethyle chitosan. Carbohydr Polym 80:1091–1101

Zamani A, Taherzadeh MJ (2010) Effects of partial dehydration and freezing temperature on the morphology and water binding capacity of carboxymethyl chitosan-based superabsorbents. Ind Eng Chem Res 49:8094–8099

Tantala JC, Rachtanapun C, Rachtanapun P (2012) Effect of molecular sizes, sources of chitosan and plasticizer types on properties of carboxymethyl chitosan films. Adv Mater Res 506:611–614

Alekseeva M, Vadim Frolov EF, Nistratov V, Smirnova L (2009) The strength of chitosan films, the role of molecular weight, the degree of order, the nature of contre-ion. Prog on Chem and Appl of Chitin and its Derivatives XIV

Caner C, Vergano PJ, Wiles JL (1998) Chitosan film mechanical and permeation properties as affected by acid, plasticizer, and storage. Food Sci Tech 63(6):1049–1053

Fernández-Pana IZK, Pedroza-Islasb R, Maté JI (2010) Effect of drying conditions on the mechanical and barrier properties of films based on chitosan. Dry Technol 28(12):1350–1358

Liu N, Chen XG, Park HJ, Liu CG, Liu CS, Meng XH, Yu LJ (2006) Effect of MW and concentration of chitosan on antibacterial activity of Escherichia coli. Carbohydr Polym 64(1):60–65

Rachtanapun P, Jakkaew M, Suriyatem R (2012) Characterization of chitosan and carboxymethyl chitosan films from various sources and molecular sizes. Adv Mater Res 506:417–420

Srinivasa PC, Ramesh MN, Tharanathan RN (2007) Effect of plasticizer and fatty acids on mechanical and permeability characteristics of chitosan. Food Hydrocoll 21(7):1113–1122

Suyatama NE, Tighzert L, Copinet A (2005) Effects of hydrophilic plasticizers on mechanical, thermal, and surface properties of chitosan films. Agric Food Chem 53(10):3950–3957

Pang HT, Chen XG, Park HJ, Cha DS, Kennedy JF (2007) Preparation and rheological properties of deoxycholate–chitosan and carboxymethyl–chitosan in aqueous systems. Carbohydr Polym 69(3):419–425

Martinez-Chamacho AP, Cortez-Rocha MO, Equerra-Brauer JM (2010) Chitosan composite films: thermal, structural, mechanical, and antifungal properties. Carbohydr Polym 82:305–315

ASTM (1995) Standard test methods for tensile properties of thin plastic sheeting. In: Annual book of ASTM. Philadelphia: American Society for Testing and Materials

ASTM (1995) Test methods for water vapor transmission of material. In: Annual book of ASTM. Philadelphia: American Society for Testing and Materials

ASTM (1995) Standard test methods for oxygen gas transmission rate through plastic film and sheeting. In: Annual book of ASTM. Philadelphia: American Society for Testing and Materials

Farag RK, Mohamed RR (2013) Synthesis and characterization of carboxymethyl chitosan nanogels for swelling studies and antimicrobial activity. Molecules 18:190–203

Bidgoli H, Zamani A, Taherzadeh MJ (2010) Effect of carboxymethylation conditions on the water-binding capacity of chitosan-based superabsorbents. Carbohydr Res 345:2683–3689

Liu M, Zhou Y, Zhang Y, Yu C, Cao S (2013) Preparation and structural analysis of chitosan films with and without sorbitol. Food Hydrocoll 33:186–191

Miranda MES, Marcolla C, Rodrígues CA, Wilhelm HM, Sierakowski MR, Bresolin TMB, Freitas RA (2006) Chitosan and N-carboxymethylchitosan: I. The role of N-carboxymethylation of chitosan in the thermal stability and dynamic mechanical properties of its films. Polym Int 55:961–969

Bourtoom T (2008) Plasticizer effect on the properties of biodegradable blend film from rice starch-chitosan. Songklanakarin J Sci Technol 30:149–165

Lamim R, Freitas RA, Rudek EI, Wilhelm HM, Cavalcanti OA, Bresolin TMB (2006) Films of chitosan and N-carboxymethylchitosan. Part II: effect of plasticizers on their physiochemical properties. Polym Int 55(8):970–977

Arvanitoyannis I, Aiba NAS (1998) Chitosan and gelatin based edible films:state diagrams, mechanical and permeation properties. J Carbohydr Polym 37(4):371–382

Bozdemir OA, Tutas M (2003) Plasticiser effect on water vapor permeability properties of locust bean gum-based edible films. Turk J Chem 27:773–782

Lazic VL, Budinski-Simendić J, Gvozdenovic JJ, Simendic B (2010) Barrier properties of coated and laminated polyolefin films for food packaging. Acta Phys Pol 117(5):855–858

Elsabee MZ, Abdou ES (2013) Chitosan based edible films and coatings: a review. Mater Sci Eng 33:1819–1841

Acknowledgments

This work was financially supported by Isfahan University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dayarian, S., Zamani, A., Moheb, A. et al. Physico-Mechanical Properties of Films of Chitosan, Carboxymethyl Chitosan, and Their Blends. J Polym Environ 22, 409–416 (2014). https://doi.org/10.1007/s10924-014-0672-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-014-0672-9