Abstract

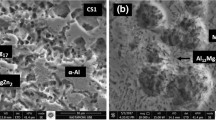

The morphologics and microhardness properties of the conventional solidified Al–5Zn–2.5Mg alloy was obtained by casting 99.99% pure Al, Zn and Mg by using a vacuum furnace and then the rapidly solidified ribbons specimens for the same alloy that was produced by using the melt-spinning technique with different wheel speeds of (10, 50 and 80) m/s. These samples have been studied by using the scanning electron microscopy, X-ray diffraction, differential thermal analysis, Vickers microhardness tester with various peak loads at room temperature. Moreover, the conventional solidified and the rapid solidified samples have been tested under a universal testing machine for the tensile tests. The scanning electron microscopy analysis shows that the conventional solidified samples have a dendritic α-Al solid solution and non-equilibrium phases. The X-ray diffraction patterns for the conventional solidified samples revealed three phases namely, two intermetallic phases (Al12Mg and MgZn2) and the α-Al phase. While no peaks corresponding to the intermetallic phases for the rapid solidified ribbons obtained by 50 and 80 m/s wheel speeds. The melting temperature for the rapid solidified ribbons of 10, 50 and 80 m/s wheel speeds were 660, 660 and 662 °C, respectively. The tensile stress curves show that there are huge enhancements in the rapid solidified samples than those in the conventional solidified samples.

Similar content being viewed by others

References

E. Karaköse, M. Keskin, Mater. Des. 32, 4970–4979 (2011)

S.J. Savage, F.H. Froes, JOM 36, 20–33 (1984)

T. Gheiratmand, H.R.M. Hosseini, P. Davami, F. Ostadhossein, M. Song, M. Gjoka, Nanoscale 16, 7520–7527 (2013)

Y.L. Wu, F.H. Froes, C. Li, A. Alvarez, Metall. Mater. Trans. A. 30, 1017–1024 (1999)

X. Xu, J. Zheng, Z. Li, R. Luo, B. Chen, Mater. Sci. Eng. A 691, 60–70 (2017)

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, Y.T. Zhu, Acta Mater. 52, 4589–4599 (2004)

G.J. Ram, T.K. Mitra, V. Shankar, S. Sundaresan, J. Mater. Process. Technol. 142, 174–181 (2003)

Y.N. Wang, J.C. Huang, Acta Mater. 55, 897–905 (2007)

E.J. Lavernia, T.S. Srivatsan, J. Mater. Sci. 45, 287–325 (2010)

I. Lichioiu, I. Peter, B. Varga, M. Rosso, J. Mater. Sci. Technol. 30, 394–400 (2014)

Y.J. Lin, B. Wu, S.L. Li, S.Y. Mao, X.J. Liu, Y.Q. Zhang, L.M. Wang, Mater. Sci. Eng. A 621, 212–217 (2015)

I. Michalcova, D. Vojtech, J. Cizek, I. Prochazka, J. Drahokoupil, P. Novak, J. Alloys Compd. 509, 3211–3218 (2011)

M. Andrzejczuk, M. Lewandowska, J. Latuch, K.J. Kurzydlowski, J. Mater. Sci. 46, 5454–5459 (2011)

L. Litynska-Dobrzynska, J. Dutkiewicz, W. Maziarz, A. Goral, Mater. Trans. A 52, 309–314 (2011)

K. Watanabe, K. Matsuda, T. Yoshida, S. Murakami, S. Ikeno, J. Jpn. Inst. Light Met. 64, 413–417 (2014)

A.K. Mukhopadhyay, Q.B. Yang, S.R. Singh, Acta Metall. Mater. 42, 3083–3091 (1994)

X.Z. LI, V. Hansen, J. Gjonnes, L.R. Wallenberg, Acta Mater. 47, 2651–2659 (1999)

R. Ferragut, A. Somoza, A. Tolley, Acta Mater. 47, 4355–4364 (1999)

L.K. Berg, J. Gjonnes, V. Hansen, X.Z. Li, M. Knutson-Wedel, G. Waterloo, D. Schryvers, L.R. Wallenberg, Acta Mater. 49, 3443–3451 (2001)

T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, B. Baroux, Acta Mater. 58, 248–260 (2010)

N. Yazdian, F. Karimzadeh, M. Tavoosi, J. Alloys Compd. 493, 137–141 (2010)

Y. Deng, L. Wan, Y. Zhang, X. Zhang, J. Alloys Compd. 509, 4636–4642 (2011)

H. Fang, R. Li, R. Chen, B. Yu, Y. Qu, S. Xun, R. Li, Trans. Nonferrous Met. Soc. China 25, 2130–2136 (2015)

E. Acer, E. Çadırlı, H. Erol, M. Gunduz, Metall. Mater. Trans. A. 16, 3484–3489 (2016)

E. Acer, E. Çadırlı, H. Erol, T. Kırındı, M. Gündüz, Mater. Sci. Eng. A 662, 144–156 (2016)

E. Karakose, M. Keskin, J. Alloys Compd. 479, 230–236 (2009)

A.G. Kostryzhev, C.D. Slater, O.O. Marenych, C.L. Davis, Sci. Rep. 6, 35715–35724 (2016)

I. Rafiei, N. Varahram, P. Davami, Metall. Mater. Eng. 19, 85–94 (2013)

N. Unlu, A. Genc, L. Ovecoglu, N. Eruslu, F.H. Froes, J. Alloys Compd. 322, 249–256 (2001)

Acknowledgements

This work was supported by Erciyes University Research Fund, Grant No: FYL-2017-7348 and Çankırı Karatekin University Research Fund, Grant No: FF200217B31.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karaköse, E., Ibrahim, A.M. & Keskın, M. The Morphological Properties and Microhardness of As-Cast and Melt-Spun Al–5Zn–2.5Mg Alloy. J Inorg Organomet Polym 28, 2645–2652 (2018). https://doi.org/10.1007/s10904-018-0929-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-018-0929-1