Abstract

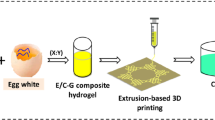

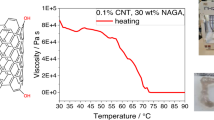

Biobased hydrogels are considered to mimic native extracellular matrix due to their high water content and are considered as adequate matrices for cell encapsulation. However, the equilibrium degree of swelling (EDS) and stiffness of simple hydrogel formulations are typically confined: Increasing polymer concentration results in increasing stiffness and simultaneously decreasing EDS. The aim of this contribution was to decouple this standard correlation between polymer content, stiffness and EDS as well as the assembly of hydrogels with graded composition of hydrogels by layer-wise printing. We investigated two sets of formulations, which consisted of three different compositions with increasing total biopolymer concentration (10.6%, 11.5%, 13.0%). Within these compositions the amount of gelatin methacryloyl acetyl (GMA) was constant (10%), whereas the proportion of methacrylated hyaluronic acid and chondroitin sulfate increased. In the first set of formulations GMA with one fixed degree of methacryloylation (DM) was used, whereby the storage modulus (G') increased from ~10 to ~25 kPa and the EDS decreased from ~700 to ~600%. In the second set of formulations we gradually lowered the DM of the GMA in parallel to increase of polymer concentration and achieved an increase of both, G' from ~11 to ~18 kPa and EDS from ~690 to ~790%. By dispensing these compositions, we created a glycosaminoglycan-graded hydrogel. We proved the cytocompatibility of the dispensing process, the used photoinitiator lithium phenyl-2,4,6-trimethylbenzoylphosphinate, and layer-wise UVA irradiation. Glycosaminoglycan gradient was proved stable for 28 d,encapsulated chondrocytes were viable and produced new matrix.

Similar content being viewed by others

References

Ahmed EM. Hydrogel: preparation, characterization, and applications: a review. J Adv Res. 2015;6:105–21.

Slaughter BV, Khurshid SS, Fisher OZ, Khademhosseini A, Peppas NA. Hydrogels in regenerative medicine. Adv Mater. 2009;21:3307–29.

Drury JL, Mooney DJ. Hydrogels for tissue engineering: scaffold design variables and applications. Biomaterials. 2003;24:4337–51.

Billiet T, Vandenhaute M, Schelfhout J, Van Vlierberghe S, Dubruel P. A review of trends and limitations in hydrogel-rapid prototyping for tissue engineering. Biomaterials. 2012;33:6020–41.

Hoch E, Hirth T, Tovar GEM, Borchers K. Chemical tailoring of gelatin to adjust its chemical and physical properties for functional bioprinting. J Mater Chem B. 2013;1:5675–85.

Okay O. General properties of hydrogels. In: Gerlach G., Arndt KF. (eds) Hydrogel Sensors and Actuators. Springer Series on Chemical Sensors and Biosensors (Methods and Applications), vol 6. Springer, Berlin, Heidelberg. 2009.

Lodish H, Berk A, Zipursky L, Matsudaira P, Baltimore D, Darnell J. Noncollagen components of the extracellular matrix.In: Molecular Cell Biology. New York: W. H. Freeman and Company; 2000. 4th edn.

Haralson M, Hassell J. Extracellular Matrix—A Practical Approach. Rickwood D, Hames B, editors. The extracellular matrix - an overview, Oxford: Oxford University Press; 1995.

Chahine NO, Chen FH, Hung CT, Ateshian GA. Direct measurement of osmotic pressure of glycosaminoglycan solutions by membrane osmometry at room temperature. Biophys J. 2005;89:1543–50.

Urban JPG. The chondrocyte: a cell under presure. Rheumatology. 1994;33:901–8.

Kular JK, Basu S, Sharma RI. The extracellular matrix: structure, composition, age-related differences, tools for analysis and applications for tissue engineering. J Tissue Eng. 2014;5:2041731414557112.

Bryant SJ, Anseth KS. Hydrogel properties influence ECM production by chondrocytes photoencapsulated in poly(ethylene glycol) hydrogels. J Biomed Mater Res A. 2002;59:63–72.

Levett PA, Hutmacher DW, Malda J, Klein TJ. Hyaluronic acid enhances the mechanical properties of tissue-engineered cartilage constructs. PLoS One. 2014;9:e113216.

Klein TJ, Malda J, Sah RL, Hutmacher DW. Tissue engineering of articular cartilage with biomimetic zones. Tissue Eng Part B Rev. 2009;15:143–57.

Annika W, Kirsten B, Günter EMT, Petra JK. Bone matrix production in hydroxyapatite-modified hydrogels suitable for bone bioprinting. Biofabrication. 2017;9:044103.

Hoch E, Tovar GEM, Borchers K. Biopolymer-based hydrogels for cartilage tissue engineering. Bioinspired, Biomim Nanobiomaterials. 2016;5:51–66.

Sant S, Hancock MJ, Donnelly JP, Iyer D, Khademhosseini A. Biomimetic gradient hydrogels for tissue engineering. Can J Chem Eng. 2010;88:899–911.

Van Vlierberghe S, Dubruel P, Schacht E. Biopolymer-based hydrogels as scaffolds for tissue engineering applications: a review. Biomacromolecules. 2011;12:1387–408.

Hoch E, Schuh C, Hirth T, Tovar GM, Borchers K. Stiff gelatin hydrogels can be photo-chemically synthesized from low viscous gelatin solutions using molecularly functionalized gelatin with a high degree of methacrylation. J Mater Sci Mater Med. 2012;23:2607–17.

Van Den Bulcke AI, Bogdanov B, De Rooze N, Schacht EH, Cornelissen M, Berghmans H. Structural and rheological properties of methacrylamide modified gelatin hydrogels. Biomacromolecules. 2000;1:31–8.

Hutson CB, Nichol JW, Aubin H, Bae H, Yamanlar S, Al-Haque S, et al. Synthesis and characterization of tunable poly(ethylene glycol): gelatin methacrylate composite hydrogels. Tissue Eng Part A. 2011;17(13 and 14):1713–23.

van den Bulcke AI, Bogdanov B, De Rooze N, Schacht EH, Cornelissen M, Berghmans H. Structural and rheological properties of methacrylamide modified gelatin hydrogels. Biomacromolecules. 2000;1:31–8.

Claassen C, Claaßen MH, Truffault V, Sewald L, Tovar Günter EM, Borchers K, et al. Quantification of substitution of gelatin methacryloyl: best practice and current pitfalls. Biomacromolecules. 2018;19:42–52.

Sewald L, Claaßen C, Götz T, Claaßen MH, Truffault V, Tovar GE, et al. Beyond the modification degree: impact of raw material on physicochemical properties of gelatin type a and type b methacryloyls. Macromol Biosci. 2018;18:1800168.

Fairbanks BD, Schwartz MP, Bowman CN, Anseth KS. Photoinitiated polymerization of PEG-diacrylate with lithium phenyl-2,4,6-trimethylbenzoylphosphinate: polymerization rate and cytocompatibility. Biomaterials. 2009;30:6702–7.

Rebers L, Granse T, Tovar GE, Southan A, Borchers K. Physical interactions strengthen chemical gelatin methacryloyl gels. Gels. 2019;5:4.

Zhou Z, Yang Z, Kong L, Liu L, Liu Q, Zhao Y, et al. Preparation and characterization of hyaluronic acid hydrogel blends with gelatin. J Macromol Sci Part B. 2012;51:2392–400.

Han F, Yang X, Zhao J, Zhao Y, Yuan X. Photocrosslinked layered gelatin-chitosan hydrogel with graded compositions for osteochondral defect repair. J Mater Sci Mater Med. 2015;26:160.

Huber B, Borchers K, Tovar GE, Kluger PJ. Methacrylated gelatin and mature adipocytes are promising components for adipose tissue engineering. J Biomater Appl. 2016;30:699–710.

Wenz A, Janke K, Hoch E, Tovar GE, Borchers K, Kluger PJ. Hydroxyapatite-modified gelatin bioinks for bone bioprinting. BioNanoMaterials. 2016;17:179–84.

Payne RG, Yaszemski MJ, Yasko AW, Mikos AG. Development of an injectable, in situ crosslinkable, degradable polymeric carrier for osteogenic cell populations. Part 1. Encapsulation of marrow stromal osteoblasts in surface crosslinked gelatin microparticles. Biomaterials. 2002;23:4359–71.

de Gans B-J, Schubert US. Inkjet printing of well-defined polymer dots and arrays. Langmuir. 2004;20:7789–93.

Acknowledgements

The authors thank Birgit Claasen and her group (Institute of Organic Chemistry, University of Stuttgart, Germany) for the 1H-NMR measurements and Martin Schenk (University of Tübingen) for the preparation of the pigs. Another thanks goes to Andreas Steinhilber, Regina Buck and Sarah Schmidt (all Fraunhofer IGB, Stuttgart, Germany) for the preparation of the biopolymer derivatives. The authors thank furthermore the Fraunhofer Gesellschaft (München, Germany) and the University of Stuttgart for providing infrastructure. Lisa Rebers thanks the Evonik Stiftung (Essen, Germany) for financial support and Eva Hoch thanks the Peter und Traudl Engelhorn Stiftung (Weilheim, Germany) for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Stier, S., Rebers, L., Schönhaar, V. et al. Advanced formulation of methacryl- and acetyl-modified biomolecules to achieve independent control of swelling and stiffness in printable hydrogels. J Mater Sci: Mater Med 30, 35 (2019). https://doi.org/10.1007/s10856-019-6231-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-019-6231-0