Abstract

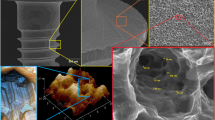

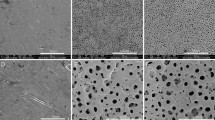

Titanium and its alloys have been used as bone-replacement implants due to their excellent corrosion resistance and biocompatibility. However, a titanium coating is a bioinert material and cannot bond chemically to bone tissue. The objective of this work was to evaluate the influence of alkaline treatment and heat treatment on the formation of calcium phosphate layer on the surface of a Ti-7.5Mo alloy after soaking in simulated body fluid (SBF). Thirty six titanium alloy plates were assigned into two groups. For group I, samples were immersed in a 5.0-M NaOH aqueous solution at 80°C for 72 h, washed with distilled water and dried at 40°C for 24 h. For group II, after the alkaline treatment, samples were heat-treated at 600°C for 1 h in an electrical furnace in air. Then, all samples were immersed in SBF for 7 or 14 days to allow the formation of a calcium phosphate coating on the surface. The surfaces were characterized using SEM, EDS, AFM and contact angle measurements.

Similar content being viewed by others

References

Gerber J, Wenaweser D, Heutz-Mayfield J, Lang NP, Persson GR. Comparison of bacterial plaque samples from titanium implant and tooth surfaces by different methods. Clin Oral Impl Res. 2006;17:1–7.

Bornstein MM, Schmid B, Lussi A, Belser VC, Buser D. Early loading of non-submerged titanium implants with a sandblasted and acid-etched surface 5-year results of a prospective study in partially edentulous patients. Clin Oral Impl Res. 2005;16:631–8.

Chahine G, Koike M, Okabe T, Smith P, Kovacevic R. The design and production of Ti-6Al-4V ELI customized dental implants. JOM. 2008;60:50–5.

Hallab NJ, Vermes C, Messina C, Roebuck KA, Glant TT, Jacobs JJ. Concentration and composition-dependent effects of metal ions on human MG-63 osteoblasts. J Biomed Mater Res. 2002;60:420–33.

Geurs NC, Jeffcoat RL, McGlumphy EA, Reddy MS, Jeffcoat MK. Influence of implant geometry and surface characteristics on progressive osseointegration. Int J Oral Maxillofac Implants. 2002;17:811.

Barrère F, van Blitterswijk CA, Meijer G, Dalmeijer RAJ, Groot K, Layrolle P. Osteointegration of biomimetic apatite coating applied onto dense and porous metal implants in femurs of goats. J Biomed Mater Res Part B. 2003;67:655–65.

Elias CN, Oshida Y, Lima JHC, Muller CA. Relationship between surface properties (roughness, wettability and morphology) of titanium and dental implant removal torque. J Mech Behav Biomed Mater. 2008;60:234–42.

Kokubo T. Apatite formation on surface ceramics, metals and polymers in body environment. Acta Mater. 1998;46:2519–27.

Wei M, Kim HM, Kokubo T, Evans JH. Optimising the bioactivity of alkaline-treated titanium alloy. Mater Sci Eng C. 2002;20:125–34.

Buser D, Broggini N, Wieland M, Schenk RK, Denzer AJ, Cochran DL, Hoffmann B, Lussi A, Steinemann SG. Enhanced bone apposition to a chemically modified SLA titanium surface. J Dent Res. 2004;83:529–33.

Rupp F, Scheideler L, Olshanska N, Wild M, Wieland M, Geis-Gestorfer J. Enhancing surface free energy and hydrophilicity through chemical modification of microstructured titanium implant surfaces. J Biomed Mater Res A. 2006;76:323–34.

Chen MF, Yang XJ, Liu Y, Zhu SL, Cui ZD, Man HC. Study on the formation of an apatite layer on NiTi shape memory alloy using a chemical treatment method. Surf Coatings Technol. 2003;173:229–34.

Giavaresi G, Fini M, Cigada A, Chiesa R, Rondelli G, Rimondini L, Torricelli P, Aldini NN, Giardino R. Mechanical and histomorphometric evaluations of titanium implants with different surface treatments inserted in sheep cortical bone. Biomaterials. 2003;24:1583–94.

Geetha M, Mudali UK, Gogia AK, Asokamani R, Ray B. Influence of microstructure and alloying elements on corrosion behavior of Ti-13Nb-13Zr alloys. Corrosion Sci. 2004;46:877–92.

Li SJ, Yang R, Niinomi M, Hao YL, Cui YY. Formation and growth of calcium phosphate on the surface of oxidized Ti-29Nb-13Ta-4.6Zr alloy. Biomaterials. 2004;25:2525–32.

Niemeyer TC, Grandini CR, Pinto LMC, Angelo ACD, Schneider SG. Corrosion behavior of Ti-13Nb-13Zr alloy used as a biomaterial. J Alloy Comp. 2009;476:172–5.

Wang TJ, Kobayashi E, Doi H, Yoneyama T. Castability of Ti-6Al-7Nb alloy for dental casting. J Med Dent Sci. 1999;46:9–13.

Ho WF, Ju CP, Chern Lin JH. Structure and properties of cast binary Ti-Mo alloys. Biomaterials. 1999;20:2115–22.

Alves APR, Santana FA, Rosa LAA, Cursino SA, Codaro EN. A study on corrosion resistance of the Ti-10Mo experimental alloy after different processing methods. Mater Sci Eng C. 2004;24:693–6.

Alves Rezende MCR, Alves APR, Codaro EN, Dutra CAM. Effect of commercial mouthwashes on the corrosion resistance of Ti-10Mo experimental alloy. J Mater Sci Mater Med. 2007;18:149–54.

Kumar S, Sankara Narayanan TSN. Corrosion behavior of Ti-15Mo alloy for dental implant applications. J Dent. 2008;36:500–7.

Lin CW, Ju CP, Lin JHC. A comparison of the fatigue behavior of cast Ti-7, 5Mo with c.p. titanium, Ti-6Al-4V and Ti-13Nb-13Zr alloys. Biomaterials. 2005;26:2899–907.

Lin DJ, Chuang CC, Lin JHC, Lee JW, Ju CP, Yin HS. Bone formation at the surface of low modulus Ti-7, 5Mo implants in rabbit femur. Biomaterials. 2007;28:2582–9.

Barrère F, Layrolle P, Van Blitterswijk CA, De Groot K. Biomimetic coatings on titanium: a crystal growth study of calcium phosphate. J Mater Sci Mater Med. 2001;12:529–34.

Barrère F, Van Blitterswijk CA, De Groot K, Layrolle P. Influence of ionic strength and carbonate on the Ca-P coating formation from SBF×5 solution. Biomaterials. 2002;23:1921–30.

Ho W-F, Lai C-H, Hsu H-C, Wu S-C. Surface modification of a low-modulus Ti-7.5Mo alloy treated with aqueous NaOH. Surf Coatings Technol. 2009;203:3142–250.

Jalota S, Bhaduri SB, Tas AC. Effect of carbonate content and buffer type on calcium phosphate formation in SBF solutions. J Mater Sci Mater Med. 2006;17:697–707.

Kim HM, Miyaji F, Kokubo T, Nakamura T. Preparation of bioactive Ti and its alloys via simple chemical surface treatment. J Biomed Mater Res. 1996;32:409–17.

Kim HM, Takadama H, Miyaji F, Kokubo T, Nishiguchi S, Nakamura T. Formation of bioactive functionally graded structure on Ti-6Al-4V alloy by chemical surface treatment. J Mater Sci Mater Med. 2000;11:555–9.

Rosenberg R, Starosvetsky D, Gotman I. Surface modification of a low modulus Ti-Nb alloy for use in medical implants. J Mater Sci Lett. 2003;22:29–32.

Jonášová L, Müller FA, Helebrant A, Strnad J, Greil P. Biomimetic apatite formation on chemically treated titanium. Biomaterials. 2004;25:1187–94.

Kokubo T, Kim HM, Kawashita M. Novel bioactive materials with different mechanical properties. Biomaterials. 2003;24:2161–75.

Choee JH, Lee SJ, Lee YM, Rhee JM, Lee HB, Khang G. Proliferation rate of fibroblast cells on polyethylene surfaces with wettability gradient. J Appl Polym Sci. 2004;92:599–606.

Faucheux N, Schweiss R, Lutzow K, Werner C, Groth T. Theoretical and experimental model to describe the injection of a polymethylmethacrylate cement into a porous structure. Biomaterials. 2004;25:2721–30.

Zhao G, Schwartz Z, Wieland M, Rupp F, Geis-Gerstorfer J, Cochran DL, Boyan BD. High surface energy enhances cell response to titanium substrate microstructure. J Biomed Mater Res A. 2005;74:49–58.

Bagno A, di Bello C. Surface treatments and roughness properties of Ti-based biomaterials. J Mater Sci Mater Med. 2004;15:935–49.

Lim JY, Donahue HJ. Biomaterial characteristics important to skeletal tissue engineering. J Musculoskelet Neuronal Interact. 2004;4:396–8.

Acknowledgments

The authors acknowledge financial support received from FAPESP (Project 00059-4/2007) and Capes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Escada, A.L.A., Machado, J.P.B., Schneider, S.G. et al. Biomimetic calcium phosphate coating on Ti-7.5Mo alloy for dental application. J Mater Sci: Mater Med 22, 2457–2465 (2011). https://doi.org/10.1007/s10856-011-4434-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4434-0