Abstract

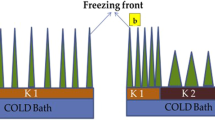

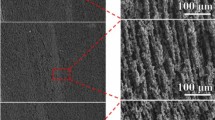

A novel freeze-gel casting/polymer sponge technique has been introduced to fabricate porous hydroxyapatite scaffolds with controlled “designer” pore structures and improved compressive strength for bone tissue engineering applications. Tertiary-butyl alcohol (TBA) was used as a solvent in this work. The merits of each production process, freeze casting, gel casting, and polymer sponge route were characterized by the sintered microstructure and mechanical strength. A reticulated structure with large pore size of 180–360 μm, which formed on burn-out of polyurethane foam, consisted of the strut with highly interconnected, unidirectional, long pore channels (~4.5 μm in dia.) by evaporation of frozen TBA produced in freeze casting together with the dense inner walls with a few, isolated fine pores (<2 μm) by gel casting. The sintered porosity and pore size generally behaved in an opposite manner to the solid loading, i.e., a high solid loading gave low porosity and small pore size, and a thickening of the strut cross section, thus leading to higher compressive strengths.

Similar content being viewed by others

References

Padilla S, Sanchez-Salcedo S, Vallet-Regi M. Bioactive and biocompatible pieces of HA/sol-gel glass mixtures obtained by the gel-casting method. J Biomed Mater Res. 2005;75A:63–72.

Cerroni L, Filocamo R, Fabbri M, Piconi C, Caropresso S, Condo SG. Growth of osteoblast like cells on porous hydroxyapatite ceramics: an in vitro study. Biomol Eng. 2002;19:119–24.

Hench LL, Wilson J. Surface-active biomaterials. Science. 1984;226:630–6.

Komlev VS, Barinov SM. Porous hydroxyapatite ceramics of bi-modal pore size distribution. J Mater Sci Mater Med. 2002;13:295–9.

Jun IK, Song JH, Choi WY, Koh YH, Kim HE. Porous hydroxyapatite scaffolds coated with bioactive apatite-wollastonite glass-ceramics. J Am Ceram Soc. 2007;90:2703–8.

Kim HW, Knowles JC, Kim HE. Hydroxyapatite porous scaffold engineered with biological polymer hybrid coating for antibiotic vancomycin release. J Mater Sci Mater Med. 2005;16:189–95.

Zhang Y, Zhang M. Three dimensional macroporous calcium phosphate bioceramics with nested chitosan sponges for load bearing bone implants. J Biomed Mater Res. 2002;61:1–8.

Zhang FZ, Kato K, Fuji M, Takahashi M. Gelcasting fabrication of porous ceramics using a continuous process. J Eur Ceram Soc. 2006;26:667–71.

Sepulveda P. Gelcasting foams for porous ceramics. Am Ceram Soc Bull. 1997;76:61–5.

Yook SW, Kim HE, Yoon BH, Soon YM, Koh YH. Improvement of compressive strength of porous hydroxyapatite scaffolds by adding polystyrene to camphene-based slurries. Mater Lett. 2009;63:955–8.

Lyckfeldt O, Ferreira JMP. Processing of porous ceramics by starch consolidation. J Eur Ceram Soc. 1998;18:131–40.

Studart AR, Gonzenbach UT, Tervoort E, Gauckler LJ. Processing routes to macroporous ceramics: a review. J Am Ceram Soc. 2006;89:1771–89.

Chu TMG, Halloran JW, Hollister SJ, Feinberg SE. Hydroxyapatite implants with designed internal architecture. J Mater Sci. 2001;12:471–8.

Sepulveda P, Binner JGP, Rogero SO, Higa OZ, Bressiani JC. Production of porous hydroxyapatite by the gel casting of foams and cytotoxic evaluation. J Biomed Mater Res. 2000;50:27–34.

Rehman H, Zhang M. Preparation of porous hydrxyapatite scaffolds by combination of the gel- casting and polymer sponge methods. Biomaterials. 2003;24:3293–302.

Lee EJ, Koh YH, Yoon BH, Kim HE, Kim HW. Highly porous hydroxyapatite bioceramics with interconnected pore channels using camphene-based freeze casting. Mater Lett. 2007;61:2270–3.

Macchetta A, Turner IG, Bowen CR. Fabrication of HA/TCP scaffolds with a graded and porous structure using a camphene-based freeze-casting method. Acta Biomater. 2009;5:1319–27.

Chen R, Wang CA, Huang Y, Ma L, Lin W. Ceramics with special porous structures fabricated by freeze-gelcasting: using tert-butyl alcohol as a template. J Am Ceram Soc. 2007;90:3478–84.

Chen R, Huang Y, Wang CA, Qi J. Ceramics with ultra-low density fabricated by gelcasting: an unconventional view. J Am Ceram Soc. 2007;90:3424–9.

Pramanik S, Agarwal AK, Rai KN, Garg A. Development of high strength hydroxyapatite by solid- state-sintering process. Ceram Inter. 2007;33:419–26.

Rodriguez-Lorenzo LM, Vallet-Regi M, Ferreira JMF. Fabrication of hydroxyapatite bodies by uniaxial pressing from a precipitated powder. Biomaterials. 2001;22:583–8.

Tampieri A, Gelotti G, Szontagh F, Landi F. Sintering and characterization of HA and TCP bioceramics with control of their strength and phase purity. J Mater Sci Mater Med. 1997;8:29–37.

Zhou J, Zhang X, Chen J, De Zeng S, Groot K. High temperature characteristics of synthetic hydroxyapatite. J Mater Sci Mater Med. 1993;4:83–5.

Kivrak N, Tas AC. Synthesis of calcium hydroxyapatite-tricalcium phosphate (HA-TCP) composite bioceramic powders and their sintering behavior. J Am Ceram Soc. 1998;81:2245–52.

Lin FH, Liao CJ, Chen KS, Sun JS, Lin CP. Petal-like apatite formed on the surface of tricalcium phosphate ceramic after soaking in distilled water. Biomaterials. 2001;22:2981–92.

Fukasawa T, Ando M. Synthesis of porous ceramics with complex pore structure by freeze-dry processing. J Am Ceram Soc. 2001;84:230–2.

Yang S, Leong KF, Du Z, Chya CK. The design of scaffolds for use in tissue engineering. Part I. Traditional factors. Tissue Eng. 2001;7:679–89.

Acknowledgements

This work was supported by the Korea Research Foundation Grant funded by the Korean Government (KRF-2008-313-D00459). Also, this study (Dr. Yang) was financially supported by Pusan National University in the program, Post-Doc. 2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, T.Y., Lee, J.M., Yoon, S.Y. et al. Hydroxyapatite scaffolds processed using a TBA-based freeze-gel casting/polymer sponge technique. J Mater Sci: Mater Med 21, 1495–1502 (2010). https://doi.org/10.1007/s10856-010-4000-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-010-4000-1