Abstract

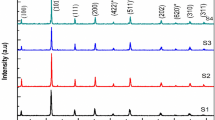

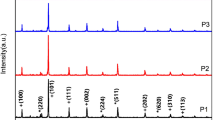

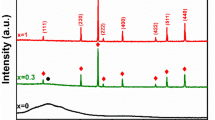

In the present work, Ni0.5Zn0.5Fe2O4/Pb0.8Zr0.2TiO3 nanocomposite with different molar ratio (1: 2, 1: 3, 1: 5, 1: 7) was prepared by hydrothermal method and sol–gel method, and the effect of molar ratio on the microstructure, dielectric and multiferroic properties was systematically investigated. X-ray diffraction and transmission electron microscopy analysis reveal inhomogeneous structures with isolated ferrite embedded into the ferroelectric (FE) matrix. Both the dielectric constant and the loss decrease firstly, and then increase with the increase of molar ratio, which is caused by the different microstructures and the formation of impurity phase. The dielectric resonance peak decreases firstly and then increases with increasing molar ratio, which is based on FE phase transition of Pb0.8Zr0.2TiO3 tuned by the magnetic phase. Among them, the nanocomposite with the molar ratio of 1:5 shows better FE properties and the lowest leakage current density, the saturation polarization, remnant polarization and coercive field are 3.74, 1.51 µC/cm2 and 7.93 kV/cm, respectively, at the measure frequency of 2 kHz. Unexpectedly, the magnetization first decreases and then increase with the increase of molar ratio, this abnormal behavior may be the result of the interface coupling effect between magnetic and FE phases. Also, this high sensitivity of multiferroic properties towards the molar ratio between magnetic and FE phases can be applied to the application in magnetoelectric devices.

Similar content being viewed by others

References

M.M. Vopson, Crit Rev Solid State Sci. 40, 223–250 (2015)

S. Dong, J.M. Liu, S.W. Cheong, Adv. Phys. 64, 519–626 (2015)

D.Z. Montanher, V.F. Freitas, J.R.D. Pereira, J. Appl. Phys. 113, 393 (2013)

F.V. Coeeal, B.D. Bueno, F.D. Carrillo, J. Appl. Phys. 99, 107 (2006)

R.L. Gao, C.L. Fu, W. Cai, G. Chen, X.L. Deng, H.R. Zhang, J.R. Sun, B.G. Shen, Sci. Rep. 6, 20330 (2016)

G. Sreenivasulu, M. Popov, A.F. Chavez, Appl. Phys. Lett. 104, 2449–2622 (2014)

R.L. Gao, H.W. Yang, J.R. Sun, Y.G. Zhao, B.G. Shen, Appl. Phys. Lett. 104, 031906 (2014)

T. Woldu, B. Raneesh, B.K. Hazra, J. Alloys Compd. 691, 644–652 (2017)

B.R. Fu, K. Gao, Y. Yang, P. Wang, Europhys. Lett. 112, 27002 (2015)

V. Folen, G. Rado, E. Stalder, Phys. Rev. Lett. 6, 607 (1961)

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, W. Cai, G. Chen, X.L. Deng, X.L. Cao, X.D. Luo, C.L. Fu, Nanoscale 10, 11750–11759 (2018)

S.G. Lu, Z.K. Xu, Y.P. Wang, S.S. Guo, J. Electroceram. 21, 398–400 (2008)

R.L. Gao, L. Bai, Z.Y. Xu, Q.M. Zhang, Z.H. Wang, W. Cai, G. Chen, X.L. Deng, C.L. Fu, Adv. Electron. Mater. 4, 18300 (2018)

K.K. Patankar, S.A. Kanade, D.S. Padalkar, B.K. Chougule, Phys. Lett. A 361, 472–477 (2007)

H. Yang, H. Wang, L. He, L. Shui, X. Yao, J. Appl. Phys. 108, 1–6 (2010)

L.N. Su, P. Liu, Y. He, J. Alloys. Compds. 494, 330–335 (2010)

R.A. Candeia, M.I.B. Bernardi, E. Longo, I.M.G. Santos, A.G. Souza, Mater. Lett. 58, 569–572 (2004)

S.B. Reddy, P.P. Singh, N. Raghu, J. Mater. Sci. 37, 929–934 (2002)

R. Suntako, P. Laoratanakul, N. Traiphol, Ceram. Int. 35, 1227–1233 (2009)

H. Zheng, J. Wang, S.E. Lofland, Science 303, 661–663 (2004)

Y. Zhang, H. Sun, W. Chen, Ceram. Int. 41, 8520–8532 (2015)

Q. Chen, P.Y. Du, L. Jin, W.J. Weng, G.R. Han, Appl. Phys. Lett. 91(1-022912-3), 022912 (2007)

J.P. Zhou, H.C. He, Y. Zhang, C.Y. Deng, Z. Shi, C.W. Nan, Appl. Phys. A89, 553–558 (2007)

A. Testino, L. Mitoseriu, V. Buscaglia, M.T. Buscaglia, I. Pallecchi, A.S. Albuquerque, V. Calzona, D. Marr’e, A.S. Siri, P. Nanni, J. Eur. Ceram. Soc. 26, 3031–3036 (2006)

C. Nayek, K.K. Sahoo, P. Murugavel, Mater. Res. Bull. 48, 1308–1311 (2013)

R. Li, F.Z. Rong, L. Zheng, Compon. Mater. 33, 23–28 (2014)

M. Popov, G. Sreenivasulu, V.M. Petrov, AIP Adv. 4, 031101–031382 (2014)

L. Zhang, J. Zhai, W. Mo, et al. Ferroelectrics 406, 213–220 (2010)

R.Y. Zheng, J. Wang, S. Ramakrishna, J. Appl. Phys. 104, 034106 (2008)

Y. Liu, Y. Wu, D. Li, J. Mater. Sci. Mater. Electron. 24, 1900–1904 (2013)

R. Sharma, P. Pahuja, R.P. Tandon, Ceram. Int. 40, 9027–9036 (2014)

R. Sharma, V. Singh, R.K. Kotnala, R.P. Tandon, Mater. Chem. Phys. 160, 447–455 (2015)

R. Grigalaitis, M.M.V. Petrović, J.D. Bobić, Ceram. Int. 40, 6165–6170 (2014)

Acknowledgements

The present work has been supported by the National Natural Science Foundation of China (Grant Nos. 51372283, 51402031, 61404018, 11647036), the Natural Science Foundation of Chongqing (CSTC2018jcyjAX0416, CSTC2015jcyjA50003, CSTC2015jcyjA50015, CSTC2016jcyjA0175, CSTC2016jcyjA0349), the Scientific and Technological Research Program of Chongqing Municipal Education Commission (KJ1501310, KJ1501318), the Excellent Talent Project in University of Chongqing (Grant No. 2017-35), the Science and Technology Innovation Project of Social Undertakings and Peoples Livelihood Guarantee of Chongqing (Grant No. cstc2017shmsA0192), the Program for Innovation Teams in University of Chongqing, China (Grant No. CXTDX201601032), the Foundation of Chongqing University of Science & Technology (CK2015B05, CK2015Z13), the Latter Foundation Project of Chongqing University of Science & Technology (CKHQZZ2008002), the Scientific & Technological Achievements Foundation Project of Chongqing University of Science & Technology (CKKJCG2016328) and the Postgraduate technology innovation project of Chongqing University of Science & Technology (YKJCX1720205).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, R., Wang, Z., Gao, R. et al. Effect of molar ratio on the microstructure, dielectric and multiferroic properties of Ni0.5Zn0.5Fe2O4-Pb0.8Zr0.2TiO3 nanocomposite. J Mater Sci: Mater Electron 29, 16226–16237 (2018). https://doi.org/10.1007/s10854-018-9712-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9712-x