Abstract

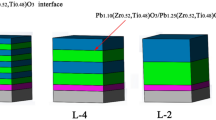

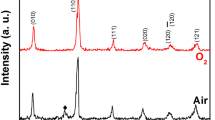

Bi0.9Gd0.1Fe0.9Co0.1O3 (BGFC) films were deposited successfully on Pt(111)/Ti/SiO2/Si(100) and SrRuO3 (SRO)/Pt(111)/Ti/SiO2/Si(100) substrates by radio frequency magnetron sputtering. Effects of sputtering power, buffer layer and film thickness on ferroelectric properties of the sputtered BGFC films were studied. X-ray diffraction demonstrated that all films had a single perovskite-type structure. Highly (012) and (024)-oriented BGFC films were formed on Pt(111)/Ti/SiO2/Si(100) and SRO/Pt(111)/Ti/SiO2/Si(100) substrates. The ferroelectric test indicated that the leakage current density of BGFC films sputtering at 40 W was smaller than that of BGFC films sputtering at 120 W, and its ferroelectric property was better than that of BGFC films sputtering at 120 W. Furthermore, the leakage current density of BGFC film with SRO buffer layer was improved and reduced by one order of magnitude under the same film thickness and sputtering power, comparing with the leakage current density of BGFC film without SRO buffer layer on Pt(111)/Ti/SiO2/Si(100) substrate. The ferroelectric property of BGFC thick film is better than that of BGFC thin film under the same sputtering power and applied electric field. The logJ–logE plots of BGFC films indicated that the leakage mechanisms of BGFC films with sputtering power of 40 and 120 W belong to the space-charge-limited conduction and Ohmic conduction, respectively. The mechanisms of the effects of sputtering power, buffer layer and film thickness on the ferroelectric properties of BGFC films were discussed.

Similar content being viewed by others

References

J. Wang, J.B. Neaton, H. Zheng, V. Nagarajan, S.B. Ogale, B. Liu, D. Viehland, V. Vaithyanathan, D.G. Schlom, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, M. Wuttig, R. Ramesh, Science 299, 1719 (2003)

P. Sharma, V. Verma, J. Magn. Magn. Mater. 374, 18–21 (2015)

M.L. Yi, C.B. Wang, Q. Shen, L.M. Zhang, J. Mater. Sci.: Mater. Electron. 25, 82–86 (2014)

P. Ravindran, R. Vidya, A. Kjekshus, H. Fjellvåg, O. Eriksson, Phys. Rev. B 74, 224412 (2006)

J. Li, J. Wang, M. Wuttig, R. Ramesh, N. Wang, B. Ruette, A.P. Pyatakov, A.K. Zvezdin, D. Viehland, Appl. Phys. Lett. 84, 5261 (2004)

J.B. Neaton, C. Ederer, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, Phys. Rev. B 71, 014113 (2005)

P. Fischer, M. Polomska, I. Sosnowska, M. Szymanski, J. Phys. C: Solid State Phys. 13, 1931 (1980)

C. Ederer, N.A. Spaldin, Phys. Rev. B 71, 060401 (2005)

F. Gao, Y. Yuan, K.F. Wang, X.Y. Chen, F. Chen, J.M. Liu, Z.F. Ren, Appl. Phys. Lett. 89, 102506 (2006)

P. Kharel, S. Talebi, B. Ramachandran, A. Dixit, V.M. Naik, M.B. Sahana, C. Sudakar, R. Naik, M.S.R. Rao, G. Lawes, J. Phys.: Condens. Matter 21, 036001 (2009)

O.D. Jayakumar, S.N. Achary, K.G. Girija, A.K. Tyagi, C. Sudakar, G. Lawes, R. Naik, J. Nisar, X. Peng, R. Ahuja, Appl. Phys. Lett. 96, 032903 (2010)

Q. Zhang, C.H. Kim, Y.H. Jang, H.J. Hwang, J.H. Cho, Appl. Phys. Lett. 96, 152901 (2010)

H. Deng, H.M. Deng, P.X. Yang, J.H. Chu, J. Mater. Sci.: Mater. Electron. 23, 1215–1218 (2012)

L.M. Kang, W. Zhang, Y. Sun, J. Ouyang, Phys. Status Solidi A 211, 565–569 (2014)

T.K. Lee, K.D. Sung, T.H. Kim, J.H. Ko, J.H. Jung, J. Appl. Phys. 116, 194101 (2014)

S.K. Pradhan, B.K. Roul, J. Phys. Chem. Solids 72, 1180–1187 (2011)

S.K. Pradhan, J. Das, P.P. Rout, S.K. Das, D.K. Mishra, D.R. Sahu, A.K. Pradhan, V.V. Srinivasu, B.B. Nayak, S. Verma, B.K. Roul, J. Magn. Magn. Mater. 322, 3614–3622 (2010)

S.K. Pradhan, J. Das, P.P. Rout, S.K. Das, S. Samantray, D.K. Mishra, D.R. Sahu, A.K. Pradhan, K. Zhang, V.V. Srinivasu, B.K. Roul, J. Alloys Compd. 509, 2645–2649 (2011)

K. Chakrabarti, B. Sarkar, V.D. Ashok, S.S. Chaudhuri, S.K. De, J. Magn. Magn. Mater. 381, 271–277 (2015)

L. Peng, H.M. Deng, J.J. Tian, Q. Ren, C. Peng, Z.P. Huang, P.X. Yang, J.H. Chu, Appl. Surf. Sci. 268, 146–150 (2013)

D.H. Kuang, P. Tang, S.H. Yang, Y.L. Zhang, J. Sol-Gel. Sci. Technol. 73, 410–416 (2015)

P. Tang, D.H. Kuang, S.H. Yang, Y.L. Zhang, J. Alloys Compd. 622, 194–199 (2015)

E.K. Akdogan, C.J. Rawn, W.D. Porter, E.A. Payzant, A. Safari et al., J. Appl. Phys. 97, 084305 (2005)

Y.S. Kim, D.H. Kim, J.D. Kim et al., Appl. Phys. Lett. 86, 102907 (2005)

S. Baba, J. Akedo, J. Cryst. Growth 275, e1247–e1252 (2005)

M.J. Chen, J.N. Ding, J.H. Qiu, N.Y. Yuan, Mater. Lett. 139, 325–328 (2015)

S. Dutta, A. Pandey, I. Yadav, O.P. Thakur, R. Laishram, R. Pal, R. Chatterjee, J. Appl. Phys. 112, 084101 (2012)

H. Yang, H. Wang, G.F. Zou, M. Jain, N.A. Suvorova, D.M. Feldmann, P.C. Dowden, R.F. DePaula, J.L. MacManus-Driscoll, A.J. Taylor, Q.X. Jia, Appl. Phys. Lett. 93, 142904 (2008)

C. Wang, M. Takahashi, H. Fujino, X. Zhao, E. Kume, T. Horiuchi, S. Sakai, J. Appl. Phys. 99, 054104 (2006)

X.D. Qi, J. Dho, R. Tomov, M.G. Blamire, J.L. MacManus-Driscoll, Appl. Phys. Lett. 86, 062903 (2005)

X. Xue, G.Q. Tan, H.F. Hao, H.J. Ren, Appl. Surf. Sci. 282, 432–438 (2013)

G.W. Pabst, L.W. Martin, Y.H. Chu, R. Ramesh, J.L. MacManus-Driscoll, Appl. Phys. Lett. 90, 072902 (2007)

Acknowledgments

This work was supported by the National Natural Science Foundation of China under Grant Nos. 61176010 and 61172027, Guangdong Natural Science Foundation under Grant No. 2014A030311049, and the Research Foundation of IARC-SYSU under Grant No. IARC 2014-09.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuang, D., Tang, P., Wu, X. et al. Effects of sputtering power, buffer layer and film thickness on ferroelectric properties of sputtered Bi0.9Gd0.1Fe0.9Co0.1O3 films. J Mater Sci: Mater Electron 27, 10173–10179 (2016). https://doi.org/10.1007/s10854-016-5094-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5094-0