Abstract

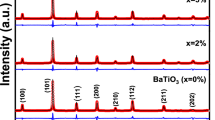

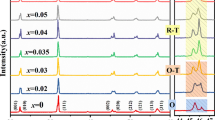

(Zr0.8Sn0.2)TiO4 (ZST) ceramics were fabricated via conventional solid-state reaction method. Sintering behavior, phase composition, microstructure and microwave dielectric properties of Y2O3–ZnO doped ZST ceramics were investigated. Only a single ZST phase was identified by X-ray diffraction patterns. The variation tendencies of dielectric constants as well as Q × f values were in accordance with the bulk densities. The appropriate Y2O3 and ZnO additions could not only efficiently lower the sintering temperature to 1240 °C, but also noticeably improve the densification and microwave dielectric properties of ZST ceramics. But excessive additives deteriorated the microstructures and comprehensive properties of samples. A dielectric constant ε r of 39.73, a Q × f value of 48,545 GHz (at 5.5 GHz), and a τ f value of −2.13 ppm/°C were obtained for 1 wt% ZnO doped ZST ceramics with 0.5 wt% Y2O3 addition sintered at 1240 °C.

Similar content being viewed by others

References

P. Zhang, Y.G. Zhao, J. Alloys Compd. 654, 240 (2016)

P. Zhang, Y.G. Zhao, Mater. Lett. 161, 620 (2015)

R. Laishram, O.P. Thakur, J. Mater. Sci. Mater. Electron. 24, 3504 (2013)

D. Pamu, G.L.N. Rao, K.C.J. Raju, J. Am. Ceram. Soc. 95(1), 126 (2012)

Y. Higuchi, H. Tamura, J. Eur. Ceram. Soc. 23(14), 2683 (2003)

J.X. Bi, C.H. Yang, H.T. Wu, J. Alloys Compd. 653, 1 (2015)

S.M. Olhero, A. Kaushal, J.M.F. Ferreira, RSC Adv. 4, 48734 (2014)

R. Laishram, O.P. Thakur, D.K. Bhattacharya, Mater. Lett. 65, 1678 (2011)

A. Ioachim, M.G. Banciu, M.I. Toacsen, Appl. Surf. Sci. 253, 335 (2006)

L.Z. Wang, L.X. Wang, Z.F. Wang et al., J. Mater. Sci. Mater. Electron. 26, 9026 (2015)

D. Pamu, G.L.N. Rao, K.C.J. Raju, T. Indian, Ceram. Soc. 67(4), 211 (2008)

X.H. Zhou, Y.Q. Zhang, X.S. Yang et al., J. Mater. Sci. Mater. Electron. 26, 7683 (2015)

H.R. Chen, Y.C. Lee, G.H. Chen et al., Ferroelectrics 434(1), 137 (2012)

B. Tang, F. Si, Y.X. Li et al., J. Electron. Mater. 43(11), 3959 (2014)

X.S. Lyu, L.X. Li, H. Sun et al., Ceram. Int. 42, 2036 (2016)

W.T. Xie, H.Q. Zhou, H.K. Zhu et al., J. Mater. Sci. Mater. Electron. 26(6), 3515 (2015)

N. Ichinose, T. Shimada, J. Eur. Ceram. Soc. 26, 1755 (2006)

Y.B. Chen, C.L. Huang, S.T. Tasi, Mater. Lett. 62, 2454 (2008)

D. Pamu, G.L.N. Rao, K.C.J. Raju, J. Alloys Compd. 475, 745 (2009)

C.L. Huang, M.H. Weng, C.C. Wu et al., Jpn. J. Appl. Phys. 40, 698 (2001)

H.C. Xiang, X.W. Jiang, L. Fang et al., J. Mater. Sci. Mater. Electron. 26, 9134 (2015)

Y.B. Chen, C.L. Huang, S.H. Lin, Mater. Lett. 60, 3591 (2006)

Acknowledgments

The authors are grateful to the support of the fund by the Practice Innovation Program (2015) for University Graduate Students of Jiangsu Province (No. SJZZ15_0095), the Priority Academic Program Development of Jiangsu Higher Education Institution (PAPD), Jiangsu Collaborative Innovation Center for Advanced Inorganic Function Composites and the Program for Innovative Research Team in University of Ministry of Education of China (No. IRT_15R35).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Q., Zhou, H., Zhu, H. et al. Sintering behavior and microwave dielectric properties of Y2O3–ZnO doped (Zr0.8Sn0.2)TiO4 ceramics. J Mater Sci: Mater Electron 27, 7750–7754 (2016). https://doi.org/10.1007/s10854-016-4762-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4762-4