Abstract

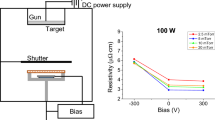

AlN films have been deposited on glass substrates at various growth conditions by DC reactive magnetron sputtering. The AlN film deposited at 300 °C shows a strongly c-axis preferred orientation with a high thermal conductivity of 12.5 W/mk. The evolution of c-axis preferential orientation, morphology, growth rate and residual stress as well as thermal conductivity of the synthesized films are investigated as a function of sputtering parameters. The crystalline quality of the films gradually improves to highly c-axis orientation as the substrate temperature increased to 300 °C. The deposition rate enhances with the substrate temperature increased or the negative bias voltage was applied. The surface roughness of the AlN films would be reduced due to the moderately increased substrate temperature or enhanced N2/Ar ratio. Moreover, it is found that high temperature and high negative bias voltage are able to grow AlN films with compressive residual stress, and the thermal conductivity of the films are improved with the increase of film thickness.

Similar content being viewed by others

References

C.K. Lee, S. Cochran, A. Abrar, K.J. Kirk, F. Placido, Ultrasonics 42, 485–490 (2004)

M.B. Assouar, O. Elmazria, M. Elhakiki, P. Alnot, J. Vac. Sci. Technol. B 22, 1717 (2004)

Y. Taniyasu, M. Kasu, T. Makimoto, Nature 441, 325–328 (2006)

O. Elmazria, V. Mortet, M. El Hakiki, M. Nesladek, P. Alnot, IEEE Trans. Ultrason. Ferroelectr. Freq. Control 50, 710–715 (2003)

W.S. Yan, R. Zhang, X.Q. Xiu, Z.L. Xie, P. Han, R.L. Jiang, S.L. Gu, Y. Shi, Y.D. Zheng, Appl. Phys. Lett. 90, 212102–212104 (2007)

D.V. Dinh, M. Conroy, V.Z. Zubialevich, N. Petkov, J.D. Holmes, P.J. Parbrook, J. Cryst. Growth 414, 94–99 (2015)

T. Kehagias, L. Lahourcade, A. Lotsari, E. Monroy, G.P. Dimitrakopulos, P. Komninou, Phys. Status Solidi B 247, 1637–1640 (2010)

D. Zhang, F.M. Liu, L.G. Cai, J. Mater. Sci.-Mater. Electron. 26, 1239–1245 (2015)

Z.P. Wang, A. Morimoto, T. Kawae, H. Ito, K. Masugata, Phys. Lett. A 375, 3007–3011 (2011)

T. Kumada, M. Ohtsuka, H. Fukuyama, AIP Adv. 5, 017136 (2015)

A.V. Singh, S. Chandra, G. Bose, Thin Solid Films 519, 5846–5853 (2011)

K. Tonisch, V. Cimalla, C. Foerster, H. Romanus, O. Ambacher, D. Dontsov, Sens. Actuators A Phys 132, 658–663 (2006)

S. Shanmugan, D. Mutharasu, P. Anithambigai, N. Teeba, I.A. Razak, J. Ceram. Process. Res. 14, 385–390 (2013)

V. Dimitrova, D. Manova, E. Valcheva, Mater. Sci. Eng. B 68, 1–4 (1999)

K. Kusaka, D. Taniguchi, T. Hanabusa, K. Tominaga, Vacuum 66, 441–446 (2002)

F. Medjani, R. Sanjinés, G. Allidi, A. Karimi, Thin Solid Films 515, 260–265 (2006)

A.L. Patterson, Phys. Rev. 56, 978–982 (1939)

Y. Shi, S. Long, S. Yang, F. Pan, Vacuum 84, 962–968 (2010)

H.C. Lee, J.Y. Lee, J. Mater. Sci.-Mater. Electron. 8, 385–390 (1997)

Q.P. Wei, X.W. Zhang, D.Y. Liu, J. Li, K.C. Zhou, D. Zhang, Z.M. Yu, Trans. Nonferrous Met. Soc. China 24, 2845–2855 (2014)

X.P. Kuang, H.Y. Zhang, G.G. Wang, L. Cui, C. Zhu, L. Jin, R. Sun, J.C. Han, Superlattices Microstruct. 52, 931–940 (2012)

P. Limsuwan, N. Udomkan, S. Meejoo, P. Winotai, Int. J. Mod. Phys. B 19, 2073–2083 (2005)

H. Zhong, Z.F. Xiao, Q.X. Jiao, J. Yang, H.L. Wang, R. Zhang, Y. Shi, J. Mater. Sci. Mater. Electron. 23, 2216–2220 (2012)

M.A. Moreira, I. Doi, J.F. Souza, J.A. Diniz, Microelectron. Eng. 88, 802–806 (2011)

X.D. Gao, E.Y. Jiang, H.H. Liu, G.K. Li, W.B. Mi, Z.Q. Li, P. Wu, H.L. Bai, Phys. Status Solidi A 204, 1130–1137 (2007)

F. Aliaj, N. Syla, S. Avdiaj, T. Dilo, Bull. Mater. Sci. 36, 429–435 (2013)

Y. Bian, M. Liu, G. Ke, Y. Chen, J. Dibattista, Surf. Coat. Technol. 267, 65–69 (2015)

Acknowledgments

This work is supported by the China Postdoctoral Science Foundation (Grant Nos. 2014M561623, 2014M551559), Jiangsu Planned Projects for Postdoctoral Research Funds (Grant No. 1401013B), the Fundamental Research Funds for Central Universities (Grant Nos. JUSRP51517, JUSRP11408, JUSRP51323B), Natural Science of Foundation of Jiangsu Province (Grant No. BK20150158), National Natural Science Foundation of Special Theoretical Physics (Grant No. 11547168), Undergraduate Training Programs for Innovation of Jiangnan University (Grant No. 2015309Y).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Zhang, Q., Yang, G.F. et al. Effect of substrate temperature and bias voltage on the properties in DC magnetron sputtered AlN films on glass substrates. J Mater Sci: Mater Electron 27, 3026–3032 (2016). https://doi.org/10.1007/s10854-015-4125-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-4125-6