Abstract

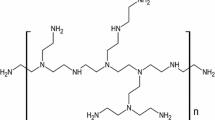

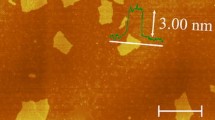

A liquid crystalline molecule, 4′-allyloxy-biphenyl-4-ol (AOBPO), was synthesized from 4,4′-dihydroxybiphenyl and allyl bromide as raw materials and then used to functionalize graphene nanoplatelets (GNS) via covalent bond and π–π interactions. The AOBPO functionalized graphene nanoplatelets (AOBPO–GNS) were characterized by fluorescence spectroscopy, thermal gravimetric analysis, Fourier transform infrared spectroscopy (FTIR), X-ray diffraction and Raman spectroscopy, and then mixed with silicone resin as fillers to fabricate silicon resin nanocomposites. The drastic quenching of the AOBPO fluorescence elucidated that the biphenyl anchoring unit of liquid crystalline AOBPO was strongly interacted with the surface of graphene sheets via π–π interactions. FTIR and Raman spectroscopy proved the existence of covalent interaction between the AOBPO and GNS. The thermal and mechanical properties testing indicated that the tensile strength of silicon resin nanocomposites increased by 463 % over that of neat silicon resin when the mass fraction of AOBPO–GNS was 1.0 %, and the elastic modulus of silicon resin nanocomposite increased by 1080 % over that of neat silicon resin if it came up to 2.0 %. The thermal conductivity of the resin filled with the AOBPO–GNS was improved to be 3.105 W/(m K) at the mass fraction of 15.0 %, which was enhanced more than 38 times over that of neat silicon resin. The resulted thermally conductive and mechanically applicable silicon resin nanocomposites could be significant in a wide variety of electronic packaging applications.

Similar content being viewed by others

References

K.S. Novoselov, A.K. Geim, S.V. Morozov, D. Jiang, Y. Zhang, S.V. Dubonos et al., Science 306, 2345 (2004)

A.K. Geim, K.S. Novoselov, Nat. Mater. 6, 183–191 (2007)

R. Fryczkowski, M. Gorczowska, C. Ślusarczyk et al., Compos. Sci. Technol. 80, 87 (2013)

H. Porwal, P. Tatarko, S. Grasso, J. Khaliq, I. Dlouhy, M. Reece, Carbon 64, 359 (2013)

C.D. Scott, S. Arepalli, P. Nikolaev, R.E. Smalley, Appl. Phys. A 72, 573 (2001)

A.A. Balandin, S. Ghosh, W. Bao, I. Calizo, D. Teweldebrhan, F. Miao et al., Nano Lett. 8, 902 (2008)

C. Lee, X. Wei, W.J. Kysar, J. Hone, Science 321, 385 (2008)

S. Chatterjee, J.W. Wang, W.S. Kuo, N.H. Tai, C. Salzmann, W.L. Li et al., Chem. Phys. Lett. 531, 6 (2012)

Y. Pan, T. Wu, H. Bao, L. Li, Carbohydr. Polym. 83, 1908 (2011)

H. Fan, L. Wang, K. Zhao, N. Li, Z. Shi, Z. Ge, Z. Jin, Biomacromolecules 11, 2345 (2010)

C.P. Wong, Silicone Resin Electronic Device Encapsulant. USA, US5051275 A, 1991–09–24

N. Gao, W. Liu, Z. Yan, Z. Wang, Opt. Mater. 35, 567 (2013)

A.W. Norris, M. Bahadur, M. Yoshitake, Proc. SPIE 5941, 594115 (2005)

Y. Liu, W. Chi, H. Duan, H. Zou, D. Yue, L. Zhang, J. Alloys Compd. (2015). doi:10.1016/j.jallcom.2015.10.129

D. Chen, F. Chen, X. Hu, H. Zhang, X. Yin, Y. Zhou, Compos. Sci. Technol. 117, 307 (2015)

Y. Song, J. Yu, L. Yu, F.E. Alama, W. Dai, C. Li et al., Mater. Des. 88, 950 (2015)

B.M. Ahmadi, F. Taheri, J. Mater. Sci. 49, 6180 (2014)

H. Suhermana, A.B. Sulong, J. Sahari, Ceram. Int. 39, 1277 (2013)

T. Ramanathan, A.A. Abdala, S. Stankovich, D.A. Dikin, M.A. Herrera, R.D. Piner et al., Nat. Nanotechnol. 3, 327 (2008)

L. Meng, C. Fu, Q. Lu, Prog. Nat. Sci. 19, 801 (2009)

M. Słoma, M. Jakubowska, A. Kolek, K. Mleczkoet, P. Ptakal, A.W. Stadler et al., J. Mater. Sci. Mater. Electron. 22, 1321 (2011)

J. Chen, Q. Chen, Q. Ma, J. Colloid Interface Sci. 370, 32 (2012)

L. Kumari, T. Zhang, G.H. Du, W.Z. Li, Q.W. Wang, A. Datye, K.H. Wu, Ceram. Int. 35, 1775 (2009)

M. Deborah, A. Jawahar, T. Mathavan, M.K. Dhas, A.M. Benial, Spectrochim. Acta. A Mol. Biomol. Spectrosc. 139, 138 (2014)

X. Shi, B. Jiang, J. Wang, Y. Yang, Carbon 50, 1005 (2012)

C.W. Reed, Dielectric polymer nanocomposites, vol. 4 (Springer, New York, 2010), p. 95

S.K. Yadav, S.S. Mahapatra, J.W. Cho, J.Y. Lee, J. Phys. Chem. C 114, 11395 (2010)

Y. Kuang, B. Huang, Polymer 56, 563 (2015)

M. Liu, Y. Duan, Y. Wang, Y. Zhao, Mater. Des. 53, 466 (2014)

M. Ahmad, E. Ahmed, Z.L. Hong, W. Ahmed, A. Elhissi, N.R. Khalid, Ultrason. Sonochem. 21, 761 (2014)

C. Li, G. Shi, J. Photochem. Photobiol. C Photochem. Rev. 19, 20 (2014)

F.M. Winnik, Chem. Rev. 93, 587 (1993)

J. Chen, H.Y. Liu, W.A. Weimer, M.D. Halls, D.H. Waldeck, G.C. Walker, J. Am. Chem. Soc. 124, 9034 (2002)

W. Gao, L.B. Alemany, L.J. Ci, P.M. Ajayan, Nat. Chem. 1, 403 (2009)

K.N. Kudin, B. Ozbas, H.C. Schniepp, R.K. Prud’homme, I.A. Aksay, R. Car, Nano. Lett. 8, 36 (2008)

S. Stankovich, D.A. Dikin, R.D. Piner, K.A. Kohlhaas, A. Kleinhammes, Y.Y. Jia et al., Carbon 45, 1558 (2007)

H. Chen, M.B. Muller, K.J. Gilmore, G.G. Wallace, D. Li, Adv. Mater. 20, 3557 (2008)

L.J. Ma, X.M. Yang, C.X. Guo, Y.W. Li, Y.F. Tu, X.L. Zhu et al., Carbon 53, 269 (2013)

Acknowledgments

Support from the National Basic Research Program of China (Program 973) (No. 2011CB605603), the Basic Research Project of Shenzhen (No. JCYJ20140418091413509) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gui, D., Xiong, W., Tan, G. et al. Improved thermal and mechanical properties of silicone resin composites by liquid crystal functionalized graphene nanoplatelets. J Mater Sci: Mater Electron 27, 2120–2127 (2016). https://doi.org/10.1007/s10854-015-4000-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-4000-5