Abstract

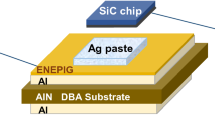

This paper explores the possibility of using Ag paste containing silicon carbide particles (SiC-p) as a novel high-temperature die-attachment solution for the design of power devices. The bonding structure used in this research was composed of silicon dies and a direct bonded copper (DBC) substrate. A SiC-p/microporous Ag composite structure was prepared by sintering a Ag microflake paste containing 2 wt% sub-micron SiC-p under mild conditions (250 °C and 0.4 MPa for 30 min). In addition to the Ag paste, the surface metallization of the DBC substrate was also evaluated in this research. Ag metallization layers deposited by electroplating and sputtering were compared, along with samples also containing a titanium (Ti) diffusion barrier layer between Cu and Ag. The results indicated that the SiC-p-containing Ag sinter paste showed better stability in storage tests than the paste without SiC-p at the temperatures such as 150, 250 and 350 °C. Additionally, the Ti diffusion barrier layer played an active role in preventing the oxidation of Cu and inter-diffusion between Cu and Ag during use at high temperatures exceeding 250 °C. The joint bonded by SiC-p-containing Ag paste on DBC substrate with Ti barrier layer exhibited excellent stability up to 1000 h at 150 and 250 °C.

Similar content being viewed by others

References

V. Benda, J. Gowar, D.A. Grant, Discrete and Integrated Power Semiconductor Devices (Wiley, New York, 1999), pp. 397–401

Y.S. Park, SiC Materials and Devices (Academic Press, San Diego, 1998), pp. 13–16

V.R. Manikam, K.Y. Cheong, IEEE Trans. Compon. Packag. Manuf. 1, 457 (2011)

R. Kisiel, Z. Szczepański, Microelectron. Reliab. 49, 627 (2009)

S. Sakamoto, T. Sugahara, K. Suganuma, J. Mater. Sci.: Mater. Electron. 24, 1332 (2012)

J. Li, C.M. Johnson, C. Buttay, W. Sabbah, S. Azzopardi, J. Mater. Process. Technol. 215, 299 (2015)

K. Xiao, J.N. Calata, H. Zheng, K.D.T. Ngo, G.Q. Lu, IEEE Trans. Compon. Packag. Manuf. Technol. 3, 1271 (2013)

G. Chen, Y. Cao, Y. Mei, D. Han, G.Q. Lu, X. Chen, IEEE Trans. Compon. Packag. Manuf. Technol. 2, 1759 (2012)

Y.-H. Mei, J.-Y. Lian, X. Chen, G. Chen, X. Li, G.-Q. Lu, IEEE Trans. Dev. Mater. Reliab. 14, 194 (2014)

J. McCoppin, T.L. Reitz, R. Miller, H. Vijwani, S. Mukhopadhyay, D. Young, J. Electron. Mater. 43, 3379 (2014)

A. Hutzler, A. Tokarski, A. Schletz, Microelectron. Reliab. 53, 1774 (2013)

R. Khazaka, L. Mendizabal, D. Henry, J. Electron. Mater. 43, 2459 (2014)

S. Sakamoto, S. Nagao, K. Suganuma, J. Mater. Sci.: Mater. Electron. 24, 2593 (2013)

H. Zhang, S. Nagao, K. Suganuma, J. Electron. Mater. 44, 3896 (2015)

F. Dugal, M. Ciappa, Microelectron. Reliab. 54, 1856 (2014)

X. Cao, T. Wang, K.D.T. Ngo, G.Q. Lu, IEEE Trans. Compon. Packag. Manuf. Technol. 1, 495 (2011)

L. Jiang, T.G. Lei, K.D.T. Ngo, G.-Q. Lu, S. Luo, IEEE Trans. Compon. Packag. Manuf. Technol. 4, 751 (2014)

Acknowledgments

This work was partially supported by a Grant-in-Aid for Scientific Research (S) (Grant No. 24226017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Nagao, S., Suganuma, K. et al. Thermostable Ag die-attach structure for high-temperature power devices. J Mater Sci: Mater Electron 27, 1337–1344 (2016). https://doi.org/10.1007/s10854-015-3894-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3894-2