Abstract

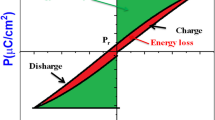

BaTiO3 (BT) nanoparticles were synthesized by a modified polymeric precursor method in a weak acid solution. The synthesized process of BT precursor with increasing calcination temperature was investigated through thermal analysis (DTA/TG), X-ray diffraction, transmission electron microscope and Fourier-transform infrared spectroscopy. Good dispersive and homogeneous cubic BT nanoparticles were calcined at 800 °C, whereas dense BT ceramics were sintered at ~1,160 °C. The present results showed that the dielectric, piezoelectric and ferroelectric properties of BT ceramics were dependent on the ceramics densification and crystallographic structure. The excellent electric properties (P r = 10.5 μC/cm2, d 33 = 217 pC/N, k p = 0.32 %) were found at a sintering temperature of 1,160 °C, which was due to the coexistence of tetragonal and orthorhombic phase. The depressed electric properties at higher sintering temperature were associated to oxygen vacancies and impurity phases. In addition, phase evolutions of BT nanoparticles and ceramics were all stated in detail.

Similar content being viewed by others

References

H. Wagata, R. Gallage, M. Yoshimura, N. Matsushita, Mater. Sci. Eng. B-Solid 146, 161 (2009)

S. Nayak, B. Sahoo, T.K. Chaki, D. Khastgir, RSC Adv. 1212, 4 (2014)

C.F. Kao, W.D. Yang, Ceram. Int. 57, 22 (1996)

C.L. Mao, X.L. Dong, T. Zeng, Mater. Lett. 1633, 61 (2007)

Y.C. Zhang, G.L. Wang, K.W. Li, M. Zhang, X.Y. Hu, H. Wang, J. Cryst. Growth. 513, 290 (2006)

A. Purwanto, W.N. Wang, I.W. Lenggoro, K. Okuyama, J. Eur. Ceram. Soc. 4489, 27 (2007)

E. Ciftci, M.N. Rahaman, M. Shumsky, J. Mater. Sci. 4875, 36 (2001)

D. Hennings, S. Schreinemacher, J. Eur. Ceram. Soc. 41, 9 (1992)

M. Veith, S. Mathur, N. Lecerf, V. Huch, T. Decker, H.P. Beck, W. Eiser, R. Haberkorn, J. Sol–Gel Sci. Technol. 145, 17 (2000)

B.A. Hernandez, K.S. Chang, E.R. Fisher, P.K. Dorhout, Chem. Mater. 480, 14 (2002)

C. Pithan, Y. Shiratori, R. Waser, J. Dornseiffer, F.H. Haegel, J. Am. Ceram. Soc. 2908, 89 (2006)

D. Gingasu, I. Mindru, L. Patron, G. Marinescu, S. Preda, J.M. Calderon-Moreno, N. Stanica, C. Andronescu, Ceram. Int. 2267, 40 (2014)

Y.B. Khollam, S.V. Bhoraskar, S.B. Deshpande, H.S. Potdar, N.R. Pavaskar, S.R. Sainkar, S.K. Date, Mater. Lett. 1871, 57 (2003)

A. Ianculescu, D. Berger, M. Viviani, C.E. Ciomaga, L. Mitoseriu, E. Vasile, N. Drăgan, D. Crişan, J. Eur. Ceram. Soc. 3655, 27 (2007)

D. Hennings, W. Mayr, J. Solid State Chem. 329, 26 (1978)

L.A. Pérez-Maqueda, M.J. Diánez, F.J. Gotor, M.J. Sayagués, C. Real, J.M. Criado, J. Mater. Chem. 2234, 13 (2003)

R. Ashiri, A. Nemati, M.S. Ghamsari, S. Sanjabi, M. Aalipour, Mater. Res. Bull. 2291, 46 (2011)

Z.M. Wang, K. Zhao, X.L. Guo, W. Sun, H.L. Jiang, X.Q. Han, X.T. Tao, Z.X. Cheng, H.Y. Zhao, H. Kimura, J. Mater. Chem. C 522, 1 (2013)

M.L. Li, H. Liang, M.X. Xu, Mater. Chem. Phys. 337, 112 (2008)

Y. Zhang, S.T. Luo, Y. Fu, K.L. Zhang, J. Mater. Sci. 3179, 41 (2006)

H.W. Wang, Mater. Chem. Phys. 1, 74 (2002)

M. Özen, M. Mertens, J. Luyten, F. Snijkers, H. D’Hondt, P. Cool, Ceram. Int. 619, 38 (2012)

Y. Terashi, A. Purwanto, W.N. Wang, F. Iskandar, K. Okuyama, J. Eur. Ceram. Soc. 2573, 28 (2008)

B.D. Begg, E.R. Vance, J. Nowotny, J. Am. Ceram. Soc. 3186, 77 (1994)

G.J. Choi, H.S. Kim, Y.S. Cho, Mater. Lett. 122, 41 (1999)

C.L. Mao, X.L. Dong, T. Zeng, G.S. Wang, S. Chen, Mater. Res. Bull. 1602, 42 (2007)

S. Kumar, G.L. Messing, W.B. White, J. Am. Ceram. Soc. 617, 76 (1993)

W.A. Sun, C.H. Li, J.Q. Li, W.N. Liu, Mater. Chem. Phys. 481, 97 (2006)

W. Lu, M. Quilitz, H. Schmidt, J. Eur. Ceram. Soc. 3149, 27 (2007)

V.A. Vasiljev, K.A. Vorotilov, M.I. Yanovskaya, L.I. Solovjeva, A.S. Sigov, J. Sol–Gel Sci. Technol. 877, 13 (1998)

E.R. Leite, C.M.G. Sousa, E. Longo, J.A. Varela, Ceram. Int. 143, 21 (1995)

M. Wang, R.Z. Zuo, S.S. Qi, L.D. Liu, J. Mater. Sci. Mater. El. 753, 23 (2012)

Y.T. Wu, X.F. Wang, C.L. Yu, E.Y. Li, Mater. Manuf. Process 1329, 27 (2012)

T. Hayashi, H. Shinozaki, K. Sasaki, J. Eur. Ceram. Soc. 1011, 19 (1999)

W.L. Luan, L. Gao, Ceram. Int. 645, 27 (2001)

A. Habib, R. Haubner, N. Stelzer, Mater. Sci. Eng. B-Solid 60, 152 (2008)

R.Z. Liu, Y.J. Zhao, H.P. Zhou, Adv. Powder Technol. 780, 24 (2014)

T.K. Mandal, Mater. Lett. 850, 61 (2007)

S.W. Zhang, H.L. Zhang, B.P. Zhang, G.L. Zhao, J. Eur. Ceram. Soc. 3235, 29 (2009)

N. Ma, B.P. Zhang, W.G. Yang, D. Guo, J. Eur. Ceram. Soc. 1059, 32 (2012)

X.G. Tang, J. Wang, X.X. Wang, H.L.W. Chan, Solid State Commun. 163, 131 (2004)

N. Lei, M.K. Zhu, P. Yang, L.L. Wang, L.F. Wang, Y.D. Hou, J. Appl. Phys. 054102, 109 (2001)

Acknowledgments

The authors would like to thank the Fundamental Research Founds for National University, China University of Geosciences (Wuhan) (CUG120118), and State Key Laboratory of Advanced Technology for Materials Synthesis Processing (Wuhan University of Technology, 2012-KF-3) for their financial support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Tian, Y., Gong, Y., Zhang, Z. et al. Phase evolutions and electric properties of BaTiO3 ceramics by a low-temperature sintering process. J Mater Sci: Mater Electron 25, 5467–5474 (2014). https://doi.org/10.1007/s10854-014-2330-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2330-3