Abstract

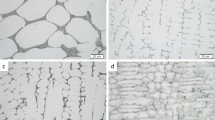

A new class of W-free, precipitation strengthened Co-base superalloys has recently been developed with improved high-temperature strength while maintaining excellent oxidation and hot corrosion resistance. In this study, we report the impact of fusion welding on microstructure and properties of an alloy of this class having a nominal composition Co–30Ni–10Al–5Mo–2Ta–2Ti. We carry out bead-on-plate laser welding of the plates and characterize the microstructure and properties of the welded samples. Fusion zone of the welds consists of FCC \(\gamma\) dendrites and an interdendritic network of ordered \(\gamma^{\prime }\) phase. Finer \(\gamma^{\prime }\) precipitates are observed inside \(\gamma\) dendrites, which form by solid-state transformation during post-solidification cooling. Measurement of phase compositions reveals differences in solid/liquid partitioning behavior of the constituent elements and indicates significant solute trapping for Mo, Ti, and Ta. Experimentally determined partition coefficients for Co and Ni agree reasonably well with thermodynamic predictions obtained using Thermo-Calc, but the prediction for Al contradicts the observations. Although welding-induced microstructural changes lead to a drop in the hardness, it was successfully restored after a post-weld solutionizing-aging treatment.

Graphical abstract

Similar content being viewed by others

References

Lee SC (1971) Precipitation-hardening characteristics of ternary cobalt-aluminum-X alloys. PhD thesis, The University of Arizona

Sato J, Omori T, Oikawa K et al (2006) Cobalt-base high-temperature alloys. Science 312:90–91. https://doi.org/10.1210/jcem-10-10-1361

Makineni SK, Samanta A, Rojhirunsakool T et al (2015) A new class of high strength high temperature Cobalt based γ–γ′ Co–Mo–Al alloys stabilized with Ta addition. Acta Mater 97:29–40. https://doi.org/10.1016/j.actamat.2015.06.034

Makineni SK, Nithin B, Chattopadhyay K (2015) A new tungsten-free γ–γ′ Co–Al–Mo–Nb-based superalloy. Scripta Mater 98:36–39. https://doi.org/10.1016/j.scriptamat.2014.11.009

Nithin B, Samanta A, Makineni SK et al (2017) Effect of Cr addition on γ–γ′ cobalt-based Co–Mo–Al–Ta class of superalloys: a combined experimental and computational study. J Mater Sci 52:11036–11047. https://doi.org/10.1007/s10853-017-1159-6

Pandey P, Sawant AK, Nithin B et al (2019) On the effect of Re addition on microstructural evolution of a CoNi-based superalloy. Acta Mater 168:37–51. https://doi.org/10.1016/j.actamat.2019.01.046

Wang Z, Zhang J, Zhang Y et al (2020) First-principles study of a tungsten-free γ–γ′ Co–Al–Mo–Nb class cobalt-based superalloy and the alloying effect of Ti addition. J Phys Soc Jpn. https://doi.org/10.7566/JPSJ.89.124714

Long FR, Baik SI, Chung DW et al (2020) Microstructure and creep performance of a multicomponent co-based L12–ordered intermetallic alloy. Acta Mater 196:396–408. https://doi.org/10.1016/j.actamat.2020.06.050

Nithin B, Chattopadhyay K, Phanikumar G (2018) Characterization of the hot deformation behavior and microstructure evolution of a new γ–γ′ strengthened cobalt-based superalloy. Metall Mater Trans A 49:4895–4905. https://doi.org/10.1007/s11661-018-4795-9

Bantounas I, Gwalani B, Alam T et al (2019) Elemental partitioning, mechanical and oxidation behaviour of two high-γ′ W-free γ/γ′ polycrystalline Co/Ni superalloys. Scripta Mater 163:44–50. https://doi.org/10.1016/j.scriptamat.2018.12.025

Klein L, Virtanen S (2012) Electrochemical characterisation of novel γ/γ′- strengthened Co-base superalloys. Electrochim Acta 76:275–281. https://doi.org/10.1016/j.electacta.2012.05.016

Liu C, Sun Y, Wen M et al (2020) Effect of Cr addition on microstructure and welding solidification cracking susceptibility of Co–Al–W based superalloys. J Manuf Process 56:820–829. https://doi.org/10.1016/j.jmapro.2020.03.049

Dupont JN, Lippold JC, Kiser SD (2011) Welding metallurgy and weldability of nickel-base alloys. Wiley, Hoboken

David SA, Babu SS, J M Vitek (1997) Weldability and microstructure development in nickel-base superalloys weldability. No. ORNL/CP-94929; CONF-9709120. Oak Ridge National Lab. (ORNL), Oak Ridge, TN (US).

Rosenthal R, West DRF (1999) Continuous γ′ precipitation in directionally solidified IN738 LC alloy. Mater Sci Technol 15:1387–1394. https://doi.org/10.1179/026708399101505518

Babu SS, David SA, Vitek JM, Miller MK (1996) Atom-probe field-ion microscopy investigation of CMSX-4 Ni-base superalloy laser beam welds. Journal De Physique IV JP. https://doi.org/10.1051/jp4:1996541

Gong L, Chen B, Du Z et al (2018) Investigation of solidification and segregation characteristics of cast Ni-base superalloy K417G. J Mater Sci Technol 34:541–550. https://doi.org/10.1016/j.jmst.2016.11.009

Cao X, Rivaux B, Jahazi M et al (2009) Effect of pre- and post-weld heat treatment on metallurgical and tensile properties of inconel 718 alloy butt joints welded using 4 kW Nd:YAG laser. J Mater Sci 44:4557–4571. https://doi.org/10.1007/s10853-009-3691-5

Zhang G, Xiao C, Taheri M (2020) Effect of Nd:YAG pulsed laser welding process on the liquation and strain-age cracking in GTD-111 superalloy. J Manuf Process 52:66–78. https://doi.org/10.1016/j.jmapro.2020.01.049

Newbury BD (2000) Thermodynamic and Solidification modeling of laser welded nickel-based alloys. Theses and dissertations

Seo SM, Lee JH, Yoo YS et al (2011) A comparative study of the γ/γ′ eutectic evolution during the solidification of Ni-base superalloys. Metall Mater Trans A 42:3150–3159. https://doi.org/10.1007/s11661-011-0738-4

Han K, Wang H, Peng F et al (2020) Effect of thermal compensation treatment on the microstructure and mechanical properties of IN738LC joint by electron beam welding. J Manuf Process 58:536–550. https://doi.org/10.1016/j.jmapro.2020.08.024

Zhang F, Levine LE, Allen AJ et al (2018) Effect of heat treatment on the microstructural evolution of a nickel-based superalloy additive-manufactured by laser powder bed fusion. Acta Mater 152:200–214. https://doi.org/10.1016/j.actamat.2018.03.017

Mantri SA, Dasari S, Sharma A et al (2021) Effect of micro-segregation of alloying elements on the precipitation behaviour in laser surface engineered alloy 718. Acta Mater 210:116844. https://doi.org/10.1016/j.actamat.2021.116844

Andersson JO, Helander T, Höglund L et al (2002) Thermo-calc & DICTRA, computational tools for materials science. Calphad 26:273–312. https://doi.org/10.1016/S0364-5916(02)00037-8

Ojo OA, Richards NL, Chaturvedi MC (2004) Microstructural study of weld fusion zone of TIG welded IN 738LC nickel-based superalloy. Scripta Mater 51:683–688. https://doi.org/10.1016/j.scriptamat.2004.06.013

Babu SS, David SA, Miller MK (1996) Microstructural development in PWA-1480 electron beam welds - an atom probe field ion microscopy study. Appl Surf Sci 94–95:280–287. https://doi.org/10.1016/0169-4332(95)00387-8

Han K, Wang H, Peng F et al (2019) Investigation of microstructure and mechanical performance in IN738LC joint by vacuum electron beam welding. Vacuum 162:214–227. https://doi.org/10.1016/j.vacuum.2018.12.047

Lass EA (2017) Application of computational thermodynamics to the design of a Co–Ni-based γ′-strengthened superalloy. Metall Mater Trans A 48:2443–2459. https://doi.org/10.1007/s11661-017-4040-y

Rappaz M, Drezet JM, Gremaud M (1999) A new hot-tearing criterion. Metall Mater Trans A 30(2):449–455. https://doi.org/10.1007/S11661-999-0334-Z

Lee HT, te Chen C, Wu JL (2010) Numerical and experimental investigation into effect of temperature field on sensitization of alloy 690 butt welds fabricated by gas tungsten arc welding and laser beam welding. J Mater Process Technol 210:1636–1645. https://doi.org/10.1016/J.JMATPROTEC.2010.05.012

Radhakrishnan B, Thompson RG (1991) A phase diagram approach to study liquation cracking in alloy 718. Metall Trans A 22(4):887–902. https://doi.org/10.1007/BF02658999

Sidhu RK, Richards NL, Chaturvedi MC (2007) Post-weld heat treatment cracking in autogenous GTA welded cast inconel 738LC superalloy. Mater Sci Technol 23:203–213. https://doi.org/10.1179/174328406X131055

Idowu OA, Ojo OA, Chaturvedi MC (2007) Effect of heat input on heat affected zone cracking in laser welded ATI Allvac 718plus superalloy. Mater Sci Eng A 454–455:389–397. https://doi.org/10.1016/J.MSEA.2006.11.054

Vishwakarma KR, Richards NL, Chaturvedi MC (2008) Microstructural analysis of fusion and heat affected zones in electron beam welded ALLVAC® 718PLUS™ superalloy. Mater Sci Eng A 480:517–528. https://doi.org/10.1016/J.MSEA.2007.08.002

Taheri M, Razavi M, Kashani-Bozorg SF, Torkamany MJ (2021) Relationship between solidification and liquation cracks in the joining of GTD-111 nickel-based superalloy by Nd:YAG pulsed-laser welding. J Mark Res 15:5635–5649. https://doi.org/10.1016/J.JMRT.2021.11.007

Ojo OA, Richards NL, Chaturvedi MC (2004) Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast inconel 738 superalloy. Scripta Mater 50:641–646. https://doi.org/10.1016/j.scriptamat.2003.11.025

Luo X, Shinozaki K, Kuroki H et al (2002) Analysis of temperature and elevated temperature plastic strain distributions in laser welding HAZ study of laser weldability of Ni-base superalloys (report 5). Weld Int 16:385–392. https://doi.org/10.1080/09507110209549547

Rowe MD (2006) Ranking the resistance of wrought superalloys to strain-age cracking. Weld J 85:27–33

Phillips VA (1968) Coherency hardening in NiAlTi alloys. Scr Metall 2:147–151. https://doi.org/10.1016/0036-9748(68)90213-5

Doong JL, Wu CS, Hwang JR (1991) Infrared temperature sensing of laser welding. Int J Mach Tools Manuf 31:607–616. https://doi.org/10.1016/0890-6955(91)90040-A

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat sources. Metall Trans B 15(2):299–305. https://doi.org/10.1007/BF02667333

Ali MA, López-Galilea I, Gao S et al (2020) Effect of γ′ precipitate size on hardness and creep properties of Ni-base single crystal superalloys: experiment and simulation. Materialia. https://doi.org/10.1016/j.mtla.2020.100692

Liu T, Yan F, Liu S et al (2016) Microstructure and mechanical properties of laser-arc hybrid welding joint of GH909 alloy. Opt Laser Technol 80:56–66. https://doi.org/10.1016/j.optlastec.2015.12.020

Cortés R, Barragán ER, López VH et al (2018) Mechanical properties of inconel 718 welds performed by gas tungsten arc welding. Int J Adv Manuf Technol 94:3949–3961. https://doi.org/10.1007/s00170-017-1128-x

Kazempour-Liasi H, Tajally M, Abdollah-Pour H (2019) Effects of pre- and post-weld heat treatment cycles on the liquation and strain-age cracking of IN939 superalloy. Eng Res Express. https://doi.org/10.1088/2631-8695/ab4d6c

Sen WH, Huang CY, Sen HK, Deng SJ (2011) Microstructure evolution of laser repair welded rené 77 nickel-based superalloy cast. Mater Trans 52:2197–2204. https://doi.org/10.2320/matertrans.M2011264

Gu YL, Tao CH, Wei ZW, Liu CK (2016) Microstructural evolution and mechanical properties of TIG welded superalloy GH625. Trans Nonferr Metals Soc China 26:100–106. https://doi.org/10.1016/S1003-6326(16)64094-3

Wang TF, Di XJ, Li CN et al (2019) Effect of δ phase on microstructure and hardness of heat-affected zone in TIG-welded GH4169 superalloy. Acta Metall Sin 32:1041–1052. https://doi.org/10.1007/s40195-018-0861-y

Angella G, Barbieri G, Donnini R et al (2017) Electron beam welding of IN792 DS: effects of pass speed and PWHT on microstructure and hardness. Materials 10:1–19. https://doi.org/10.3390/ma10091033

Peng F, Zhang B, Wang H, Han K (2019) Effect of pre-weld heat treatment on the microstructure and mechanical properties of electron beam welded IN738LC joint. Vacuum 168:108857. https://doi.org/10.1016/j.vacuum.2019.108857

Acknowledgements

KSA and SC gratefully acknowledge the financial grant from DSTFIST, India, (SR/FST/ETI-421/2016) for the FESEM facility at IITH. KC and PP thank the Gas Turbine Materials and Processes (GTMAP) programme of Aeronautics Research and Development Board, DRDO for support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

This manuscript contains no conflict of interest that could potentially influence or bias this submission.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Athira, K.S., Pandey, P., Prabhakar, K.V.P. et al. Laser welding of a W-free precipitation strengthened Co-base superalloy. J Mater Sci 57, 7085–7100 (2022). https://doi.org/10.1007/s10853-022-07117-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07117-8