Abstract

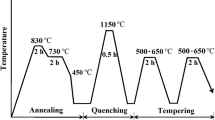

H13 die steels with varied yttrium (Y) content were prepared by vacuum induction melting, multiple forging, annealing and quenching treatment with stepwise heating. The effects of Y on the microstructures, internal fraction and martensitic transformation of H13 die steel were investigated using electron backscattering diffraction, transmission electron microscopy and a multifunctional internal friction meter. The results showed that the martensite start temperature first decreased but then increased with the increasing Y content, reaching a minimum in the 0.013Y-H13 steel. The refinement of the prior austenite grain size afforded more nucleation sites in Y-modified H13 die steels. The Snoek–Köster–Kê peak indicated that the solid solution of Y atoms provided additional martensitic transformation dynamics to increase the martensitic transformation rate and promote the formation of V1−V2 (Σ3) variants during the initial stage of transformation. The transformation rate decreased in Y-modified H13 steels during the late stage of transformation (70% completed). Therefore, the addition of Y elements was beneficial for refining the size of the martensite and promoted the formation of twin-type martensite in H13 steel.

Similar content being viewed by others

References

Coldwell H, Woods R, Paul M, Koshy P, Dewes R, Aspinwall D (2003) Rapid machining of hardened AISI H13 and D2 moulds, dies and press tools. J Mater Process Technol 135(2–3):301–311

Taktak S (2007) Some mechanical properties of borided AISI H13 and 304 steels. Mater Des 28(6):1836–1843

Wang Y, Song K, Zhang Y, Wang G (2019) Microstructure evolution and fracture mechanism of H13 steel during high temperature tensile deformation. Mater Sci Eng A 746:127–133

Chen R, Wang Z, He J, Zhu F, Li C (2020) Effects of rare earth elements on microstructure and mechanical properties of H13 die steel. Metals 10(7):918–929

Zhu J, Xie J, Zhang Z, Huang H (2018) Microstructure and obdurability improvement mechanisms of the La-Microalloyed H13 steel. Steel Res Int 89(12):1–10

Jiang Z, Wang P, Li D, Li Y (2020) Effects of rare earth on microstructure and impact toughness of low alloy Cr-Mo-V steels for hydrogenation reactor vessels. J Mater Sci Technol 45:1–14

Chen R, Wang Z, Zhu F, Zhao H, Qin J, Zhong L (2020) Effects of rare-earth micro-alloying on microstructures, carbides, and internal friction of 51CrV4 steels. J Alloy Compd 824:1–13

Kotan H (2018) Thermal stability, phase transformation and hardness of mechanically alloyed nanocrystalline Fe-18Cr-8Ni stainless steel with Zr and Y2O3 additions. J Alloy Compd 749:948–954

Kotan H, Darling KA (2017) Phase transformation and grain growth behavior of a nanocrystalline 18/8 stainless steel. Mater Sci Eng A 686:168–175

Kotan H (2015) Microstructural evolution of 316L stainless steels with yttrium addition after mechanical milling and heat treatment. Mater Sci Eng A 647:136–143

Gao X, Ren H, Wang H, Chen S (2017) Effect of lanthanum on the precipitation and dissolution of NbC in microalloyed steels. Mater Sci Eng A 683:116–122

Jiang Z, Wang P, Li D, Li Y (2020) Effects of rare earth on microstructure and impact toughness of low alloy Cr–Mo–V steels for hydrogenation reactor vessels. J Mater Sci Technol 45:1–14

Du C, Jin S, Fang Y, Li J, Hu S, Yang T, Zhang Y, Huang J, Sha G, Wang Y, Shang Z, Zhang X, Sun B, Xin S, Shen T (2018) Ultrastrong nanocrystalline steel with exceptional thermal stability and radiation tolerance. Nat Commun 9:1–9

Zhao Y, Wang J, Zhou S, Wang X (2014) Effects of rare earth addition on microstructure and mechanical properties of a Fe-15Mn-1.5Al-0.6C TWIP steel. Mater Sci Eng A 608:106–113

Gao J, Fu P, Liu H, Li D (2015) Effects of rare earth on the microstructure and impact toughness of H13 steel. Metals 5(1):383–394

Yang X-S, Sun S, T.–Y. Zhang, (2015) The mechanism of bcc α′ nucleation in single hcp ε laths in the fcc γ → hcp ε → bcc α′ martensitic phase transformation. Acta Mater 95:264–273

Ghosh G, Olson GB (1994) Kinetics of F.C.C.→B.C.C. heterogeneous martensitic nucleation—I. The critical driving force for athermal nucleation. Acta Metall Mater 42:3361–3370

Hanamura T, Torizuka S, Tamura S, Enokida S, Takechi H (2013) Effect of austenite grain size on transformation behavior, microstructure and mechanical properties of 0.1C–5Mn martensitic steel. ISIJ Int 53:2218–2225

Lee S-J, Park K-S (2013) Prediction of martensite start temperature in alloy steels with different grain sizes. Metall Mater Trans A 44:3423–3427

Shirdel M, Mirzadeh H, Parsa MH (2015) Nano/ultrafine grained austenitic stainless steel through the formation and reversion of deformation-induced martensite: mechanisms, microstructures, mechanical properties, and TRIP effect. Mater Charact 103:150–161

Celada-Casero C, Sietsma J, Santofimia MJ (2019) The role of the austenite grain size in the martensitic transformation in low carbon steels. Mater Des 167:1–10

Stormvinter A, Miyamoto G, Furuhara T, Hedström P, Borgenstam A (2012) Effect of carbon content on variant pairing of martensite in Fe–C alloys. Acta Mater 60:7265–7274

Zhu J, Lin GT, Zhang ZH, Xie JX (2020) The martensitic crystallography and strengthening mechanisms of ultra-high strength rare earth H13 steel. Mater Sci Eng A 797:1–12

Wang Q, Zhang M, Liu W, Cheng D, Wei X, Xu J, Chen J, Lu H, Yu C (2019) On the martensitic transition manner within the transition martensitic zone of the dissimilar steel interface. Mater Des 179:1–11

Huang SK, Wen YH, Li N, Teng J, Ding S, Xu YG (2008) Application of damping mechanism model and stacking fault probability in Fe–Mn alloy. Mater Charact 59(6):681–687

Bevington PR (1969) Data reduction and error analysis, or the physical science. McGraw-Hill, New York, p 235

Zhou T, Faleskog J, Babu RP, Odqvist J, Yu H, Hedström P (2019) Exploring the relationship between the microstructure and strength of fresh and tempered martensite in a maraging stainless steel Fe–15Cr–5Ni. Mater Sci Eng A 745:420–428

Schoeck G (1963) Friccion interna debido a la interaccion entre dislocaciones Y atomos solutos. Acta Metall. 11(6):617–622

Huang SK, Huang WR, Liu JH, Teng J, Li N, Wen YH (2013) Internal friction mechanism of Fe-19Mn alloy at low and high strain amplitude. Mater Sci Eng A 560:837–840

Hao F, Liao B, Li D, Dan T, Ren X, Yang Q, Liu L (2011) Effects of rare earth oxide on hardfacing metal microstructure of medium carbon steel and its refinement mechanism. J Rare Earths 29(6):609–613

Turnbull D (1950) Kinetics of heterogeneous nucleation. J Chem Phys 18:198–203

Chen YZ, Wang K, Shan GB, Ceguerra AV, Huang LK, Dong H, Cao LF, Ringer SP, Liu F (2018) Grain size stabilization of mechanically alloyed nanocrystalline Fe-Zr alloys by forming highly dispersed coherent Fe-Zr-O nanoclusters. Acta Mater 158:340–353

Cohen M (1992) Martensitic nucleation—revisited. Mater Trans JIM 33:178–183

Olson GB, Cohen M (1975) Kinetics of strain-induced martensitic nucleation. Metall Mater Trans A 6:791–795

Chen L, Ma X, Jin M, Wang J, Long H, Mao T (2015) Beneficial effect of microalloyed rare earth on S segregation in high-purity duplex stainless steel. Metall Mater Trans A 47(1):33–38

Miyamoto G, Iwata N, Takayama N, Furuhara T (2013) Variant selection of lath martensite and bainite transformation in low carbon steel by ausforming. J Alloy Compd 577:S528–S532

Morito S, Tanaka H, Konishi R, Furuhara T, Maki T (2003) The morphology and crystallography of lath martensite in Fe–C alloys. Acta Mater 51:1789–1799

Wu BB, Wang ZQ, Wang XL, Xu WS, Shang CJ, Misra RDK (2019) Toughening of martensite matrix in high strength low alloy steel: regulation of variant pairs. Mater Sci Eng A 759:430–436

Patel JR, Cohen M (1953) Criterion for the action of applied stress in the martensitic transformation. Acta Metall 1:531–538

Kaneshita T, Miyamoto G, Furuhara T (2017) Variant selection in grain boundary nucleation of bainite in Fe-2Mn-C alloys. Acta Mater 127:368–378

Qi L, Khachaturyan AG, Morris JW (2014) The microstructure of dislocated martensitic steel: theory. Acta Mater 76:23–39

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51704132) and the Key Research and Development Program of Jiangxi Province (Grant Nos. 20192ACB50010, 20192BBEL50016). Longyi Heavy Rare Earths Co., Ltd., is also gratefully acknowledged for providing the raw materials and the RE alloy; additionally, thanks are expressed to Goal Science for their technical support in alloy smelting and processing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors listed have approved the manuscript that is enclosed. We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product.

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Rc., Wang, Zg., Wang, Hb. et al. Effects of yttrium on the microstructures, internal fraction and martensitic transformation in H13 die steel. J Mater Sci 56, 7753–7764 (2021). https://doi.org/10.1007/s10853-020-05731-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05731-y