Abstract

Efforts to construct predictive grain boundary (GB) structure–property models have historically relied on property measurements or calculations made on bicrystals. Experimental bicrystals can be difficult or expensive to fabricate, and computational constraints limit atomistic bicrystal simulations to high-symmetry GBs (i.e., those with small enough GB periodicity). Although the use of bicrystal property data to construct GB structure–property models is more direct, in many experimental situations the only type of data available may be measurements of the effective properties of polycrystals. In this work, we investigate the possibility of inferring GB structure–property models from measurements of the homogenized effective properties of polycrystals when the form of the structure–property model is unknown. We present an idealized case study in which GB structure–property models for diffusivity are inferred from noisy simulation results of two-dimensional microstructures, under the assumption that the number of polycrystal measurements available is larger than the number of parameters in the inferred model. We also demonstrate how uncertainty quantification for the inferred structure–property models is easily performed within this framework.

Similar content being viewed by others

Notes

We use the term “property localization” to distinguish this problem from the more frequently studied problem of inferring the local state (e.g., the local stress tensor) from the macroscopic state (e.g., the effective stress tensor) of a polycrystal [8,9,10,11,12,13,14], which we refer to as “state localization.”

The code implements the method established by [28], and is available at http://mason.mse.ucdavis.edu/wp-content/uploads/2018/01/FTGG2_v1_0.zip.

In the absence of a measured structure–property model, computational studies have typically employed a discrete binary model with low- and high-angle GBs possessing different constant values of properties [26, 40], though there are some studies that have employed continuous functions (see [41] for an example).

It is worth noting that a useful alternative Bayesian formulation of inverse problems exists, as described by [45, 46], which results in a conditional a posteriori density \(\sigma (\mathbf{x}\! \mid \! \mathbf{y})\). We have chosen to follow the approach introduced by Tarantola [44], which results in the joint a posteriori density \(\sigma (\mathbf{y},\mathbf{x})\) and avoids the, perhaps rare, mathematical singularity that can exist in \(\sigma (\mathbf{x}\! \mid \! \mathbf{y})\) for events with vanishing probability (Borel’s paradox).

This is rather flexible, and we find that in some cases even strongly nonlinear theoretical relations can be considered.

References

Kaur I, Mishin Y, Gust W (1995) Fundamentals of grain and interphase boundary diffusion, 3rd edn. Willey, Hoboken

Hugo RC, Hoagland RG (2000) The kinetics of gallium penetration into aluminum grain boundaries—in situ TEM observations and atomistic models. Acta Mater 48(8):1949–1957. https://doi.org/10.1016/S1359-6454(99)00463-2

Olmsted DL, Foiles SM, Holm EA (2009) Survey of computed grain boundary properties in face-centered cubic metals: I. Grain boundary energy. Acta Mater 57(13):3694–3703. https://doi.org/10.1016/j.actamat.2009.04.007

Olmsted DL, Holm EA, Foiles SM (2009) Survey of computed grain boundary properties in face-centered cubic metals-II: grain boundary mobility. Acta Mater 57(13):3704–3713. https://doi.org/10.1016/j.actamat.2009.04.015

Rollett AD, Yang CC, Mullins WW, Adams BL, Wu CT, Kinderlehrer D, Ta’asan S, Manolache F, Liu C, Livshits I, Mason D, Talukder A, Ozdemir S, Casasent D, Morawiec A, Saylor D, Rohrer GS, Demirel M, El-Dasher B, Yang W (2001) Grain boundary property determination through measurement of triple junction geometry and crystallography. Recryst Grain 1(2):165–175

Read WT, Shockley W (1950) Dislocation models of crystal grain boundaries. Phys Rev 78(3):275–289

Bulatov VV, Reed BW, Kumar M (2014) Grain boundary energy function for FCC metals. Acta Mater 65:161–175. https://doi.org/10.1016/j.actamat.2013.10.057

Binci M, Fullwood D, Kalidindi SR (2008) A new spectral framework for establishing localization relationships for elastic behavior of composites and their calibration to finite-element models. Acta Mater 56(10):2272–2282. https://doi.org/10.1016/j.actamat.2008.01.017

Fast T, Kalidindi SR (2011) Formulation and calibration of higher-order elastic localization relationships using the MKS approach. Acta Mater 59(11):4595–4605. https://doi.org/10.1016/j.actamat.2011.04.005

Fullwood DT, Kalidindi SR, Adams BL, Ahmadi S (2009) A discrete fourier transform framework for localization relations. Comput Mater Continua 9(1):25–39. https://doi.org/10.3970/cmc.2009.009.025

Kalidindi SR, Landi G, Fullwood DT (2008) Spectral representation of higher-order localization relationships for elastic behavior of polycrystalline cubic materials. Acta Mater 56(15):3843–3853. https://doi.org/10.1016/j.actamat.2008.01.058

Landi G, Kalidindi SR (2010) Thermo-elastic localization relationships for multi-phase composites. Comput Mater Continua 16(3):273–293. https://doi.org/10.3970/cmc.2010.016.273

Yabansu YC, Patel DK, Kalidindi SR (2014) Calibrated localization relationships for elastic response of polycrystalline aggregates. Acta Mater 81:151–160. https://doi.org/10.1016/j.actamat.2014.08.022

Yabansu YC, Kalidindi SR (2015) Representation and calibration of elastic localization kernels for a broad class of cubic polycrystals. Acta Mater 94:26–35. https://doi.org/10.1016/j.actamat.2015.04.049

Li DY, Szpunar JA (1992) Determination of single crystals’ elastic constants from the measurement of ultrasonic velocity in the polycrystalline material. Acta Metall Mater 40(12):3277–3283. https://doi.org/10.1016/0956-7151(92)90041-C

Hayakawa M, Imai S, Oka M (1985) Determination of single-crystal elastic constants from a cubic polycrystalline aggregate. J Appl Crystallogr 18:513–518. https://doi.org/10.1107/S0021889885010809

Patel DK, Al-Harbi HF, Kalidindi SR (2014) Extracting single-crystal elastic constants from polycrystalline samples using spherical nanoindentation and orientation measurements. Acta Mater 79:108–116. https://doi.org/10.1016/j.actamat.2014.07.021

Gold L (1950) Evaluation of the stiffness coefficients for beryllium from ultrasonic measurements in polycrystalline and single crystal specimens. Phys Rev 77(3):390–395. https://doi.org/10.1103/PhysRev.77.390

Wright SI (1994) Estimation of single-crystal elastic constants from textured polycrystal measurements. J Appl Crystallogr 27(5):794–801. https://doi.org/10.1107/S0021889894001883

Gnäupel-Herold T, Brand PC, Prask HJ (1998) Calculation of single-crystal elastic constants for cubic crystal symmetry from powder diffraction data. J Appl Crystallogr 31(6):929–935. https://doi.org/10.1107/S002188989800898X

Haldipur P, Margetan FJ, Thompson RB (2004) Estimation of single-crystal elastic constants from ultrasonic measurements on polycrystalline specimens. AIP Conf Proc 700(2004):1061–1068. https://doi.org/10.1063/1.1711735

Haldipur P, Margetan FJ, Thompson RB (2006) Estimation of single-crystal elastic constants of polycrystalline materials from back-scattered grain noise. AIP Conf Proc 820(II(2006)):1133–1140. https://doi.org/10.1063/1.2184652

Gasteau D, Chigarev N, Ducousso-Ganjehi L, Gusev VE, Jenson F, Calmon P, Tournat V (2016) Single crystal elastic constants evaluated with surface acoustic waves generated and detected by lasers within polycrystalline steel samples. J Appl Phys 119(4):043103. https://doi.org/10.1063/1.4940367

Du X, Zhao JC (2017) Facile measurement of single-crystal elastic constants from polycrystalline samples. npj Comput Mater 3(1):1–7. https://doi.org/10.1038/s41524-017-0019-x

Sha G (2018) A simultaneous non-destructive characterisation method for grain size and single-crystal elastic constants of cubic polycrystals from ultrasonic measurements. Insight: Non-Destr Test Cond Monit 60(4):190–193. https://doi.org/10.1784/insi.2018.60.4.190

Johnson OK, Li L, Demkowicz MJ, Schuh CA (2015) Inferring grain boundary structure-property relations from effective property measurements. J Mater Sci 50(21):6907–6919. https://doi.org/10.1007/s10853-015-9241-4

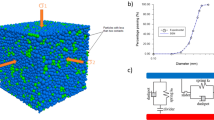

Johnson OK, Lund JM, Critchfield TR (2018) Spectral graph theory for characterization and homogenization of grain boundary networks. Acta Mater 146:42–54. https://doi.org/10.1016/j.actamat.2017.11.054

Lazar EA, MacPherson RD, Srolovitz DJ (2009) A more accurate two-dimensional grain growth algorithm. Acta Mater 58:364–372. https://doi.org/10.1016/j.actamat.2009.09.008

Frary M, Schuh CA (2005) Grain boundary networks: scaling laws, preferred cluster structure, and their implications for grain boundary engineering. Acta Mater 53(16):4323–4335. https://doi.org/10.1016/j.actamat.2005.05.030

Gertsman VY, Tangri K (1995) Computer simulation study of grain boundary and triple junction distributions in microstructures formed by multiple twinning. Acta Metall Mater 43(6):2317–2324

Johnson OK, Schuh CA (2013) The uncorrelated triple junction distribution function: towards grain boundary network design. Acta Mater 61(8):2863–2873. https://doi.org/10.1016/j.actamat.2013.01.025

Fortier P, Miller WA, Aust KT (1997) Triple junction and grain boundary character distributions in metallic materials. Acta Mater 45(8):4–9

Yi YS, Kim JS (2004) Characterization methods of grain boundary and triple junction distributions. Scripta Mater 50(6):855–859. https://doi.org/10.1016/j.scriptamat.2003.12.010

Davies P, Randle V, Watkins G, Davies H (2002) Triple junction distribution profiles as assessed by electron backscatter diffraction. J Mater Sci 37(19):4203–4209. https://doi.org/10.1023/A:1020052306493

Rollett AD, Barmak K (2014) Orientation mapping. In: Laughlin DE, Hono K (eds) Physical metallurgy. Elsevier, Amsterdam, pp 1113–1141. https://doi.org/10.1016/B978-0-444-53770-6.00011-3

Brough I, Bate PS, Humphreys FJ (2006) Optimising the angular resolution of EBSD. Mater Sci Technol 22(11):1279–1286. https://doi.org/10.1179/174328406X130902

Zaefferer S (2007) On the formation mechanisms, spatial resolution and intensity of backscatter Kikuchi patterns. Ultramicroscopy 107(2–3):254–266. https://doi.org/10.1016/j.ultramic.2006.08.007

Kacher J, Landon C, Adams BL, Fullwood D (2009) Bragg’s Law diffraction simulations for electron backscatter diffraction analysis. Ultramicroscopy 109(9):1148–1156. https://doi.org/10.1016/j.ultramic.2009.04.007

Wilkinson AJ, Meaden G, Dingley DJ (2006) High-resolution elastic strain measurement from electron backscatter diffraction patterns: New levels of sensitivity. Ultramicroscopy 106(4–5):307–313. https://doi.org/10.1016/j.ultramic.2005.10.001

Chen Y, Schuh CA (2006) Diffusion on grain boundary networks: percolation theory and effective medium approximations. Acta Mater 54(18):4709–4720. https://doi.org/10.1016/j.actamat.2006.06.011

Moghadam MM, Rickman JM, Harmer MP, Chan HM (2015) The role of boundary variability in polycrystalline grain-boundary diffusion. J Appl Phys 117(4):045311. https://doi.org/10.1063/1.4906778

Tarantola A, Valette B (1982) Inverse problems = quest for information. J Geophys 50(3):159–170. https://doi.org/10.1038/nrn1011

Mosegaard K, Tarantola A (2002) Probabilistic approach to inverse problems. In: Lee WH, Jennings P, Kisslinger C, Kanamori H (eds) International handbook of earthquake and engineering seismology (Part A). Academic Press, Cambridge, pp 237–265. https://doi.org/10.1016/S0074-6142(02)80219-4

Tarantola A (2005) Inverse problem theory and methods for model parameter estimation. Society for Industrial and Applied Mathematics, Philadelphia

Aggarwal R, Demkowicz MJ, Marzouk YM (2015) Bayesian inference of substrate properties from film behavior. Modell Simul Mater Sci Eng 23(1):15. https://doi.org/10.1088/0965-0393/23/1/015009

Aggarwal R, Demkowicz MJ, Marzouk YM (2016) Information-driven experimental design in materials science. In: Lookman T, Alexander FJ, Rajan K (eds) Information science for materials discovery and design, vol 225. Springer, Berlin, pp 13–44. https://doi.org/10.1007/978-3-319-23871-5

Johnson OK, Schuh CA (2018) Texture mediated grain boundary network design in three dimensions. Mech Mater 118:94–105. https://doi.org/10.1016/j.mechmat.2017.12.001

Biscondi M (1984) Intergranular diffusion and grain-boundary structure. In: Lacombe P (ed) Physical chemistry of the solid state: applications to metals and their compounds. Elsevier Science Publishers B.V, Amsterdam, pp 225–239

Sommer J, Herzig C, Mayer S, Gust W (1989) Grain boundary self-diffusion in silver bicrystals. Defect Diffus Forum 66–69:843–848

Quey R, Dawson PR, Barbe F (2011) Large-scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. Comput Methods Appl Mech Eng 200(17–20):1729–1745. https://doi.org/10.1016/j.cma.2011.01.002

Quey R (2017) Neper Reference Manual; The documentation for Neper 3.0.2; A software package for polycrystal generation and meshing. http://neper.sourceforge.net/

Quey R, Renversade L (2018) Optimal polyhedral description of 3D polycrystals: method and application to statistical and synchrotron X-ray diffraction data. Comput Methods Appl Mech Eng 330:308–333. https://doi.org/10.1016/j.cma.2017.10.029

Quey R, Polycrystal Generation and Meshing | Neper 3.0.2. http://neper.sourceforge.net/

Weinzierl S (2000) Introduction to Monte Carlo methods. arXiv:0006269

Kolmogorov AN (1956) Foundations of the theory of probability, Second English edn. Chelsea Publishing Company, New York English translation edited by Nathan Morrison

Acknowledgements

The material presented here is based upon work supported by the National Science Foundation under Grant No. 1610077. We thank Jarrod M. Lund and Tyler R. Critchfield for their assistance in developing the Monte Carlo code to assign grain orientations for the two-dimensional polycrystal templates. We would also like to show our gratitude for the guidance and insights from David Page and Akash Amalaraj during the course of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Derivation of diffusivity homogenization equation

The derivation of Eq. 1 is related to the idea of [40] that one can obtain the effective diffusivity from Fick’s First law by considering the flux across some “slice” through the microstructure. However, in contrast to [40], we are interested in the effective diffusivity of the entire GBN, rather than the average diffusivity of individual GBs in the network; the two ideas are, nevertheless, intimately related (see footnote 1 in [26]). Our approach to calculate the effective diffusivity of the entire GBN is equivalent to an adaptation of the finite volume method (see [27]). For convenience, we set the concentration at the source node (node a) to be \(c_0\) and consider the total flux (\(J_b = Q_b/A\)) arriving at the sink node (node b), whose concentration we fix at 0 (Neumann boundary conditions). The effective diffusivity is then

and the mass flow rate arriving at the sink is simply

where \(D_{ib}\), \(A_{ib}\), and \(L_{ib}\) are, respectively, the diffusivity, cross-sectional area, and length of the edge connecting node i to node b, \(c_k\) is the concentration at node k, and the sum is over all edges in the GBN that are incident to node b (\(i \sim b\) denotes that there is an edge between nodes i and b). Making use of the definition of the GBN Laplacian matrix (\(\mathcal{L}\)) [27], this can be rewritten as

where \(\mathcal{L}_b\) is the bth column of \(\mathcal{L}\) and c is a vector containing the concentration at every node, which is calculated by solving the linear system of equations defined by

where \(\widehat{\mathcal{L}}\) is a matrix formed by replacing the ath and bth rows of \(\mathcal{L}\) with \(e_a^{\intercal }\) and \(e_b^{\intercal },\) respectively, and where \(e_k\) is a vector having the kth element equal to one and all others equal to zero. We note that Eq. 20 is simply a statement of conservation of mass at every node. Substituting the solution of Eq. 20 into Eq. 19 and substituting the result into Eq. 17, we arrive at Eq. 1. We note also that the direct inversion of \(\widehat{\mathcal{L}}\) is not necessary for the solution of Eq. 20, and is not computationally efficient; rather, standard methods for the solution of linear systems of equations will be preferred. In our implementation of Eq. 1, we employ MATLAB’s mldivide operator.

Appendix B: Inverse problem theory

Here we give a brief overview of relevant aspects of Tarantola’s approach to Bayesian inverse problem theory, and then demonstrate its application to the problem of GB property localization. Inverse problem theory is a method of inferring model parameters \((\mathbf{x})\) that characterize a system using the results of some measurements/observations of the system \((\mathbf{y})\) [42,43,44,45,46]. In a given system, \({\mathbf{x}}=\left\{ x_1,x_2,\dots \right\} \) is a set containing the independent parameters and \({\mathbf{y}}=\left\{ y_1,y_2,\dots \right\} \) is a set containing the dependent parameters, both of which we may only hope to know with some imperfect degree of certainty. TarantolaFootnote 5 proposed that our state of information (what we know about \(\mathbf{y}\) and \(\mathbf{x}\)) can be described by a PDF, called the a posteriori state of information, \(\sigma (\mathbf{y},\mathbf{x})\), which is equal to the conjunction of the a priori state of information, \(\rho (\mathbf{y},\mathbf{x})\), and the theoretical state of information, \(\Theta (\mathbf{y},\mathbf{x})\) [44]. The a priori state of information is what we know before ever making any observations and may represent some known physical constraints. The theoretical state of information encodes correlations between \(\mathbf{x}\) and \(\mathbf{y}\) resulting from a homogenization or other physical theory and corresponding uncertainty. Using the Kolmogorov axioms, Tarantola and Valette showed that the a posteriori state of information is given by [42]:

Here, k is a normalization constant, and \(\mu (\mathbf{y},\mathbf{x})\) is the homogeneous state of information, which is the PDF that assigns a probability to each region of the parameter space that is equal to the volume of that region [43]. Functionally, \(\mu (\mathbf{y},\mathbf{x})\) represents a state of complete ignorance (i.e., the absence of any a priori information), so that the ratio in Eq. 21 can be interpreted as quantifying how much is known relative to a state of complete ignorance. In the present context, Eq. 1 represents the forward problem, where the dependent parameter is the observed effective diffusivity \(\mathbf{y}=\{\bar{D}^{\text{obs}}\}\) and the independent parameters are the structure–property model and sample microstructure \(\mathbf{x}=\{\mathscr{D},M\}\). As described in the “GB property localization” section, GB property localization will typically leverage information from multiple samples, so that we have \({\mathbf{M}}=\{M_1,M_2,\ldots ,M_N\}\) and \({\bar{\mathbf{D}^{\text{obs}}}}=\{\bar{D}_1^{\text{obs}},\bar{D}_2^{\text{obs}},\ldots ,\bar{D}_N^{\text{obs}}\}\). Ignoring the normalization constant, we can then rewrite Eq. 21 as:

The resolution of the inverse problem consists in identifying the structure–property model, \(\mathscr{D}\), that is most probable given our observations of \({\bar{\mathbf{D}^{\text{obs}}}}\) and \({\mathbf{M}}\). This is accomplished by integrating Eq. 22 to compute the a posteriori state of information over the space of independent parameters:

The evaluation of this integral is facilitated by considering relevant simplifications. Because the a priori information about \(\mathbf{M}\) and \(\mathscr{D}\) is not obtained from measurements of \({\bar{\mathbf{D}^{\text{obs}}}}\), their states of information are independent [44], which implies that:

It should be noted here that subscripts are used to distinguish the functions.

Let us assume that Eq. 1, as the physical theory relating the independent and dependent parameters, is at most mildlyFootnote 6 nonlinear. Combining this assumption with the Kolmogorov definition for conditional probability [55], and taking the homogeneous probability of the independent parameters as their marginal probability, \(\Theta ({\bar{\mathbf{D}^{\text{obs}}},\mathscr{D},\mathbf{M}})\) can be written, according to the treatment of Tarantola and Vallete [42, 44], as:

Substituting Eqs. 22 and 24–26 into Eq. 23, we obtain:

Because the manifold that \({\bar{\mathbf{D}^{\text{obs}}}}\) inhabits is a linear space, using the definition of homogeneous probability distribution presented by Mosegaard and Tarantola [43], \(\mu ({\bar{\mathbf{D}^{\text{obs}}}})\) is constant. We also make the simplifying approximation that any uncertainty in Eq. 1 is negligible, which implies that \(\theta \left({\bar{\mathbf{D}^{\text{obs}}}}\mid{\{\mathscr{D},\mathbf{M}\}}\right) =\delta ({\bar{\mathbf{D}^{\text{obs}}}}-{\bar{\mathbf{D}^{\text{pred}}}}(\mathscr{D},{\mathbf{M}}))\). Under these conditions, the integration operation in Eq. 27 results in:

which is the result given in Eq. 3. The last term, \(\rho _{\bar{\mathbf{D}^{\text{obs}}}}\left({\bar{\mathbf{D}^{\text{pred}}}}(\mathscr{D},{\mathbf{M}})\right) \), is a likelihood function, which quantifies how well the model explains the data. In other words, \(\rho _{\bar{\mathbf{D}^{\text{obs}}}}\left({\bar{\mathbf{D}^{\text{pred}}}}(\mathscr{D},{\mathbf{M}})\right) \) quantifies how well the independent parameters explain the dependent parameters. Thus, for the conditions presented here, the a posteriori state of information about the independent parameters is proportional to the product of the likelihood function and the a priori state of information about the independent parameters.

Rights and permissions

About this article

Cite this article

Kurniawan, C., Baird, S., Fullwood, D.T. et al. Grain boundary structure–property model inference using polycrystals: the overdetermined case. J Mater Sci 55, 1562–1576 (2020). https://doi.org/10.1007/s10853-019-04125-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04125-z