Abstract

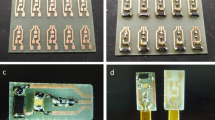

The polymer–metal interface is one of the most critical parts in polymer-based neural implants in relation to their long-term reliability. In this study, we aim to suggest a feasible fabrication method using mechanical interlocking to improve polymer–metal adhesion in polymer-based neural electrodes and evaluate its impact on device reliability in vitro. Liquid crystal polymer (LCP) is selected as the base material for the polymer-based neural electrode due to its extremely low water absorption rate (<0.04 %). Test samples with mechanical interlocked interface between LCP and a noble metal are designed and fabricated using micro-patterning technologies, in this case photolithography, electroplating, and laser machining. After the metal patterns with undercut profile cross sections were fabricated using a dual photolithography process and electroplating, the LCP and the metal formed a mechanical interlocking pattern during the lamination process. In a 180° peel test, the average maximum adhesion force of the samples with and without mechanical interlocking was 19.24 and 14.27 N, respectively. In vitro accelerated soak tests, which consist of interdigitated electrode patterns and a customized system for measuring the leakage current, are carried out to evaluate the long-term reliability of the LCP-based neural electrodes. Samples with and without interlock failed after 224 and 185 days, respectively, in a 75 °C saline environment. Scanning electron microscopy images revealed that the interlocked LCP–metal interfaces remained intact after water leakage. The results demonstrate the effect of the fabrication method using mechanical interlocking, which can be applicable to other polymer-based neural electrodes for long-term implantation.

Similar content being viewed by others

References

Hassler C, Boretius T, Stieglitz T (2011) Polymers for neural implants. J Polym Sci B 49:18–33

Hwang G-T, Im D, Lee SE et al. (2013) In vivo silicon-based flexible radio frequency integrated circuits monolithically encapsulated with biocompatible liquid crystal polymers. ACS Nano 7:4545–4553

Kang K, Choi IS, Nam Y (2011) A biofunctionalization scheme for neural interfaces using polydopamine polymer. Biomaterials 32:6374–6380

Lee SW, Min KS, Jeong J et al. (2011) Monolithic encapsulation of implantable neuroprosthetic devices using liquid crystal polymers. IEEE Trans Biomed Eng 58:2255–2263

Liu C (2007) Recent developments in polymer MEMS. Adv Mater 19:3783–3790

Bhatti PT, Arcand BY, Wang J et al. (2006) A 32-site 4-channel high-density electrode array for a cochlear prosthesis. IEEE J Solid-State Circuits 41:2965–2973

Wang J, Wise KD (2008) A hybrid electrode array with built-in position sensors for an implantable MEMS-based cochlear prosthesis. J Microelectromech Syst 17:1187–1194

Wang J, Wise KD (2009) A thin-film cochlear electrode array with integrated position Sensing. J Microelectromech Syst 18:385–395

Cheung KC, Renaud P, Tanila H et al. (2007) Flexible polyimide microelectrode array for in vivo recordings and current source density analysis. Biosens Bioelectron 22:1783–1790

Chang JHC, Yang L, Dongyang K et al. (2013) Reliable packaging for parylene-based flexible retinal implant. Solid-state sensors, actuators and microsystems (TRANSDUCERS & EUROSENSORS XXVII), 2013 transducers & eurosensors XXVII: the 17th international conference on 2612–2615. doi:10.1109/Transducers.2013.6627341

Rodger DC, Fong AJ, Li W et al. (2008) Flexible parylene-based multielectrode array technology for high-density neural stimulation and recording. Sensor Actuat B 132:449–460

Wen L, Rodger DC, Meng E et al. (2010) Wafer-level parylene packaging with integrated RF electronics for wireless retinal prostheses. J Microelectromech Syst 19:735–742

Corbett S, Ketterl J, Johnson T (2006) Polymer-based microelectrode arrays. Mater Res Soc Symp. doi:10.1557/PROC-0926-CC06-02

Chow EY, Chlebowski AL, Irazoqui PP (2010) A miniature-implantable RF-wireless active glaucoma intraocular pressure monitor. IEEE Trans Biomed Circuits Syst 4:340–349

Gwon TM, Min KS, Kim JH et al. (2015) Fabrication and evaluation of an improved polymer-based cochlear electrode array for a traumatic insertion. Biomed Microdev 17:1–12

Jeong J, Bae SH, Min KS et al. (2015) A miniaturized, eye-conformable, and long-term reliable retinal prosthesis using monolithic fabrication of liquid crystal polymer (LCP). IEEE Trans Biomed Eng 62:982–989

Lee SE, Jun SB, Lee H et al. (2012) A flexible depth probe using liquid crystal polymer. IEEE Trans Biomed Eng 59:2085–2094

Xuefeng W, Jonathan E, Chang L (2003) Liquid crystal polymer (LCP) for MEMS: processes and applications. J Micromech Microeng 13:628–633

Jeong J, Bae SH, Seo JM et al. (2016) Long-term evaluation of a liquid crystal polymer (LCP)-based retinal prosthesis. J Neural Eng 13:25004

Loeb GE, Peck RA (1996) Cuff electrodes for chronic stimulation and recording of peripheral nerve activity. J Neurosci Methods 64:95–103

Ordonez JS, Boehler C, Schuettler M et al. (2012) Improved polyimide thin-film electrodes for neural implants. Engineering in Medicine and Biology Society (EMBC), 2012 annual international conference of the IEEE, pp 5134–5137. doi:10.1109/EMBC.2012.6347149

Richardson RR, Miller JA, Reichert WM (1993) Polyimides as biomaterials: preliminary biocompatibility testing. Biomaterials 14:627–635

Hassler C, von Metzen RP, Ruther P et al. (2010) Characterization of parylene C as an encapsulation material for implanted neural prostheses. J Biomed Mater Res B 93:266–274

Jui-Mei H, Rieth L, Normann RA et al. (2009) Encapsulation of an integrated neural interface device with parylene C. IEEE Trans Biomed Eng 56:23–29

Sharma A, Rieth L, Tathireddy P et al. (2012) Evaluation of the packaging and encapsulation reliability in fully integrated, fully wireless 100 channel Utah Slant Electrode Array (USEA): implications for long term functionality. Sens Actuators A 188:167–172

von Metzen R, Stieglitz T (2013) The effects of annealing on mechanical, chemical, and physical properties and structural stability of Parylene C. Biomed Microdev 15:727–735

Xie X, Rieth L, Williams L et al. (2014) Long-term reliability of Al2O3 and parylene C bilayer encapsulated Utah electrode array based neural interfaces for chronic implantation. J Neural Eng 11:16–26

Leng A, Streckel H, Hofmann K et al. (1998) The delamination of polymeric coatings from steel Part 3: effect of the oxygen partial pressure on the delamination reaction and current distribution at the metal/polymer interface. Corros Sci 41:599–620

Leng A, Streckel H, Stratmann M (1998) The delamination of polymeric coatings from steel. Part 2: first stage of delamination, effect of type and concentration of cations on delamination, chemical analysis of the interface. Corros Sci 41:579–597

Leng A, Streckel H, Stratmann M (1998) The delamination of polymeric coatings from steel. Part 1: calibration of the Kelvinprobe and basic delamination mechanism. Corros Sci 41:547–578

Kim W-S, Yun I-H, Lee J-J et al. (2010) Evaluation of mechanical interlock effect on adhesion strength of polymer–metal interfaces using micro-patterned surface topography. Int J Adhes Adhes 30:408–417

LeGoues FK, Silverman BD, Ho PS (1988) The microstructure of metal–polyimide interfaces. J Vac Sci Technol A 6:2200–2204

Packham DE (2003) Surface energy, surface topography and adhesion. Int J Adhes Adhes 23:437–448

Venables JD (1984) Adhesion and durability of metal–polymer bonds. J Mater Sci 19:2431–2453. doi:10.1007/978-1-4613-2749-3_27

McCabe JF, Carrick TE, Kamohara H (2002) Adhesive bond strength and compliance for denture soft lining materials. Biomaterials 23:1347–1352

Rubehn B, Stieglitz T (2010) In vitro evaluation of the long-term stability of polyimide as a material for neural implants. Biomaterials 31:3449–3458

Haddad PR, Jackson PE (1990) Ion chromatography. Elsevier, Amsterdam

Kinloch A (2012) Adhesion and adhesives: science and technology. Springer, New York

Ordonez J, Schuettler M, Boehler C et al. (2012) Thin films and microelectrode arrays for neuroprosthetics. Mater Res Soc Bull 37:590–598. doi:10.1557/mrs.2012.117

Widge AS (2007) Self-assembled monolayers of polythiophene “Molecular wires”: a new electrode technology for neuro-robotic interfaces. PhD Dissertation, University of Pittsburgh

Reclaru L, Meyer JM (1994) Study of corrosion between a titanium implant and dental alloys. J Dent 22:159–168

Venugopalan R, Lucas LC (1998) Evaluation of restorative and implant alloys galvanically coupled to titanium. Dent Mater 14:165–172

Rouya E, Cattarin S, Reed ML et al. (2012) Electrochemical characterization of the surface area of nanoporous gold films. J Electrochem Soc 159:97–102

El-Deab MS, Arihara K, Ohsaka T (2004) Fabrication of Au(111)-like polycrystalline gold electrodes and their applications to oxygen reduction. J Electrochem Soc 151:213–218

Vanhoestenberghe A, Donaldson N (2011) The limits of hermeticity test methods for micropackages. Artif Organs 35:242–244

Aihara K, Chen MJ, Cheng C et al. (2012) Reliability of liquid crystal polymer air cavity packaging. IEEE Trans Compon Packag Manuf 2:224–230

Pham A-V (2011) Packaging with liquid crystal polymer. IEEE Microw Mag 5:83–91

Celina M, Gillen KT, Assink RA (2005) Accelerated aging and lifetime prediction: review of non-Arrhenius behaviour due to two competing processes. Polym Degrad Stabil 90:395–404

Hukins DWL, Mahomed A, Kukureka SN (2008) Accelerated aging for testing polymeric biomaterials and medical devices. Med Eng Phys 30:1270–1274

Chun W, Chou N, Cho S et al. (2014) Evaluation of sub-micrometer parylene C films as an insulation layer using electrochemical impedance spectroscopy. Prog Org Coat 77:537–547

Acknowledgements

This work was supported in part by a Grant to CABMC (Control of Animal Brain using MEMS Chip) funded by Defense Acquisition Program Administration (UD140069ID) and in part by BK21 Plus Project, Department of Electrical and Computer Engineering, SNU in 2015 and in part by Engineering-Dentistry Interdisciplinary Research grant jointly funded by College of Engineering and College of Dentistry, Seoul National University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

No conflict of interest.

Rights and permissions

About this article

Cite this article

Gwon, T.M., Kim, J.H., Choi, G.J. et al. Mechanical interlocking to improve metal–polymer adhesion in polymer-based neural electrodes and its impact on device reliability. J Mater Sci 51, 6897–6912 (2016). https://doi.org/10.1007/s10853-016-9977-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-9977-5