Abstract

A grade 2 pure Ti was processed by high-pressure torsion (HPT) under 3.0 GPa for 10 revolutions to achieve an improved strength. Wear tests revealed that HPT only slightly improved the wear resistance of pure Ti. Subsequently, a TiN coating with a thickness of 2.5 μm was deposited on different Ti substrates to improve the wear resistance. Both indentation and scratch testing demonstrated a much improved load-bearing capacity when ultrafine-grained Ti was chosen as the substrate compared with coarse-grained Ti. All results indicate that pure Ti processed by HPT, when combined with a subsequent coating, represents a good candidate material for bio-implant applications.

Similar content being viewed by others

References

Latysh V, Krallics G, Alexandrov I, Fodor A (2006) Curr Appl Phys 6:262

Valiev RZ, Semenova IP, Latysh VV, Rack H, Lowe TC, Petruzelka J, Dluhos L, Hrusak D, Sochova J (2008) Adv Eng Mater 10:B15

Semenova IP, Polyakov AV, Raab GI, Lowe TC, Valiev RZ (2012) J Mater Sci 47:7777

Edalati K, Horita Z (2012) Rev Adv Eng Mater 31:5

Wang JT, Li Z, Wang J, Langdon TG (2012) Scr Mater 67:810

Arzaghi M, Fundenberger JJ, Toth LS, Arruffat R, Faure L, Beausir B, Sauvage X (2012) Acta Mater 60:4393

Okazaki Y, Gotoh E (2005) Biomaterials 26:11

Okazaki Y, Gotoh E (2008) Corros Sci 50:3429

Li Y, Wong C, Xiong J, Hodgson P, Wen C (2010) J Dent Res 89:493

Makihira S, Mine Y, Nikawa H, Shuto T, Iwata S, Hosokawa R, Kamoi K, Okazaki S, Yamaguchi Y (2010) Toxicol In Vitro 24:1905

Long M, Rack HJ (1998) Biomaterials 19:1621

Elias CN, Lima JHC, Valiev R, Meyers MA (2008) JOM 6(3):46

Diomidis N, Mischler S, More NS, Roy M (2012) Acta Biomater 8:852

La P, Ma J, Zhu YT, Yang J, Liu W, Xue Q, Valiev RZ (2005) Acta Mater 53:5167

Gao N, Wang CT, Wood RJK, Langdon TG (2012) J Mater Sci 47:4779

Wang CT, Gao N, Wood RJK, Langdon TG (2011) J Mater Sci 46:123

Figueiredo RB, Pereira PHR, Aguilar MTP, Cetlin PR, Langdon TG (2012) Acta Mater 60:3190

Xu C, Horita Z, Langdon TG (2008) Acta Mater 56:5168

Wang CT, Gao N, Wood RJK, Langdon TG (2011) Mater Sci Forum 667–669:1101

Sakai G, Horita Z, Langdon TG (2005) Mater Sci Eng, A 393:344

Wang CT, Gao N, Gee MG, Wood RJK, Langdon TG (2012) Wear 280:28

Wang CT, Gao N, Gee MG, Wood RJ, Langdon TG (2013) J Mech Behav Biomed Mater 17:166

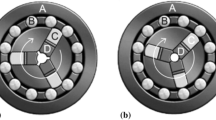

Gee MG, Nunn JW, Muniz-Piniella A, Orkney LP (2011) Wear 271:2673

Vidakis N, Antoniadis A, Bilalis N (2003) J Mater Process Technol 143:481

Wang CT, Escudeiro A, Polcar T, Cavaleiro A, Wood RJK, Gao N, Langdon TG (2013) Wear (in press)

Zhao X, Fu W, Yang X, Langdon TG (2008) Scr Mater 59:542

Zhao X, Yang X, Liu X, Wang X, Langdon TG (2010) Mater Sci Eng, A 527:6335

Ko YG, Shin DH, Park KT, Lee CS (2006) Scr Mater 54:1785

Yapici GG, Karaman I, Maier HJ (2006) Mater Sci Eng, A 434:294

Stolyarov VV, Zeipper L, Mingler B, Zehetbauer M (2008) Mater Sci Eng, A 476:98

Kang D-H, Kim T-W (2010) Mater Des 31:S54

Purcek G, Yapici GG, Karaman I, Maier HJ (2011) Mater Sci Eng, A 528:2303

Zhang Y, Figueiredo RB, Alhajeri SN, Wang JT, Gao N, Langdon TG (2011) Mater Sci Eng, A 528:7708

Sordi VL, Ferrante M, Kawasaki M, Langdon TG (2012) J Mater Sci 47:7870

Stolyarov VV, Zhu YT, Lowe TC, Islamgaliev RK, Valiev RZ (1999) Nanostruct Mater 11:947

Sergueeva AV, Stolyarov VV, Valiev RZ, Mukherjee AK (2001) Scr Mater 45:747

Stolyarov VV, Zhu YT, Alexandrov IV, Lowe TC, Valiev RZ (2001) Mater Sci Eng, A 299:59

Stolyarov VV, Zhu YT, Lowe TC, Valiev RZ (2001) Mater Sci Eng, A 303:82

Stolyarov VV, Zhu YT, Alexandrov IV, Lowe TC, Valiev RZ (2003) Mater Sci Eng, A 343:43

Semenova IP, Valiev RZ, Yakushina EB, Salimgareeva GH, Lowe TC (2008) J Mater Sci 43:7354

Islamgaliev RK, Kazyhanov VU, Shestakova LO, Sharafutdinov AV, Valiev RZ (2008) Mater Sci Eng, A 493:190

Faghihi S, Li D, Szpunar JA (2010) Nanotechnol 21:485703

Garbacz H, Gradzka-Dahlke M, Kurzydlowski KJ (2007) Wear 263:572

Purcek G, Saray O, Kul O, Karaman I, Yapici GG, Haouaoui M, Maier HJ (2009) Mater Sci Eng, A 517:97

Faghihi S, Azari F, Zhilyaev AP, Szpunar JA, Vali H, Tabrizian M (2007) Biomaterials 28:3887

Bindu S, Sanosh KP, Smetana K, Balakrishnan A, Kim TN (2009) J Mater Sci Technol 25:556

Balyanov A, Kutnyakova J, Amirkhanova NA, Stolyarov VV, Valiev RZ, Liao XZ, Zhao YH, Jiang YB, Xu HF, Lowe TC, Zhu YT (2004) Scr Mater 51:225

Acknowledgements

The authors acknowledge support from the University of Southampton together with a scholarship from the China Scholarship Council (CTW). This work was also partially supported by the EPSRC under Grant No. EP/D00313X/1 and the National Science Foundation of the United States under Grant No. DMR-1160966 (TGL).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C.T., Gao, N., Gee, M.G. et al. Tribology testing of ultrafine-grained Ti processed by high-pressure torsion with subsequent coating. J Mater Sci 48, 4742–4748 (2013). https://doi.org/10.1007/s10853-012-7110-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7110-y