Abstract

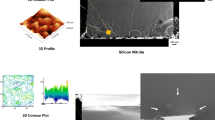

Fractal dimension has been considered as a measure of fracture surface roughness of materials. Three-dimensional (3D) surface analysis is anticipated to provide a better evaluation of fracture surface toughness and fractal dimension. The objective of this study was to quantify the fracture surfaces and identify a potential relationship between fracture toughness and fractal dimension in a new type of core–shell titanium–iron particulate reinforced hydroxyapatite matrix composites using SEM stereoscopy coupled with a 3D surface analysis. The obtained results showed that both fracture surface roughness and fractal dimension increased with increasing amount of core–shell Ti–Fe reinforcing particles. The fractal dimension was observed to be a direct measure of fracture surface roughness. The fracture toughness of the composites increased linearly with the square root of fractal dimensional increment (i.e., followed the Mecholsky–Mackin equation well) due to the presence of Ti–Fe particles along with the effect of porosity in brittle materials. The 3D fractal analysis was suggested to be a proper tool for quantifying the fracture surfaces and linking the microstructural parameter to fracture toughness.

Similar content being viewed by others

References

Mandelbrot BB (2000) The fractal geometry of nature, revised edn, 19th printing. W.H. Freeman and Company, New York

Gomory R (2010) Nature 468:378

Peitgen H-O (2010) Science 330:926

Coster M, Chermant JL (1983) Int Metals Rev 28:228

Mandelbrot BB, Passoja DE, Paullay AJ (1984) Nature 308:721

Mandelbrot BB (2006) Int J Fract 138:13

Cahn RW (1989) Nature 338:201

Lakes R (1993) Nature 361:511

Schaefer DW (1989) Science 243:1023

Meakin P (1991) Science 252:226

Wang ZG, Chen DL, Jiang XX, Ai SH, Shih CH (1988) Scripta Metall 22:827

Williford RE (1990) Scripta Metall Mater 24:455

Charkaluk E, Bigerelle M, Iost A (1998) Eng Fract Mech 61:119

Yang AM, Xiong YH, Liu L (2001) Sci Technol Adv Mater 2:101

Kotowski P (2006) Int J Fract 141:269

Venkatesh B, Chen DL, Bhole S (2008) Scripta Mater 59:391

Tanaka M, Ono J, Sakashita M, Kato R (2009) ISIJ Int 49:1229

Chappard D, Degasne I, Huré G, Legrand E, Audran M, Baslé MF (2003) Biomaterials 24:1399

Tanaka M (1995) J Mater Sci 30:3668. doi:https://doi.org/10.1007/BF00351883

Hilders OA, Ramos M, Pena ND, Saenz L (2006) J Mater Sci 41:5739. doi:https://doi.org/10.1007/s10853-006-0102-z

Chen CT, Runt J (1989) Polym Commun 30:334

Kozlov HV, Burya OI, Aloev VZ (2004) Mater Sci 40:491

Du PH, Xue B, Song YH, Lu SJ, Yu J, Zheng Q (2010) Polym Bull 64:185

Blacher S, Maquet V, Schils F, Martin D, Schoenen J, Moonen G et al (2003) Biomaterials 24:1033

Mecholsky JJ, Passoja DE, Feinberg-Ringel KS (1989) J Am Ceram Soc 72:60

Wasen J, Heier E, Hansson T (1998) Scripta Mater 38:953

Chen Z, Mecholsky JJ, Joseph T, Beatty CL (1997) J Mater Sci 32:6317. doi:https://doi.org/10.1023/A:1018657731971

Mechtcherine V (2009) Cem Concr Res 39:620

Jiang MQ, Meng JX, Gao JB, Wang XL, Rouxel T, Keryvin V et al (2010) Intermetallics 18:2468

Chen DL, Pang DX, Yang ZJ, Kong S, Wang LT, Yang K et al (1988) J Phys C 21:271

Fratini M, Poccia N, Ricci A, Campi G, Burghammer M, Aeppli G et al (2010) Nature 466:841

Zaanen J (2010) Nature 466:825

Rishabh A, Joshi MR, Balani K (2010) J Appl Phys 107:123532. doi:https://doi.org/10.1063/1.3445869

Liang JZ, Wu CB (2010) Mater Sci Technol 18:178

Liang JZ, Wu CB (2009) J Mater Eng 10:53

Liang JZ, Wu CB (2008) J Appl Polym Sci 109:3763

Cantor GJ, Brown CA (2009) Wear 266:609

Briones V, Aguilera JM, Brown C (2006) J Food Eng 77:776

Dougherty G, Henebry GM (2001) Med Eng Phys 23:369

Wolski M, Podsiadlo P, Stachowiak GW (2009) Proc IMechE H 223:211

Majumder SR, Mazumdar S (2007) Physica A 377:559

Gentile F, Tirinato L, Battista E, Causa F, Liberale C, di Fabrizio EM et al (2010) Biomaterials 31:7205

Wang P, Li L, Zhang C, Lei QF, Fang WJ (2010) Biomaterials 31:6201

Borodinsky LN, Fiszman ML (2001) Methods 24:341

Mecholsky JJ (2009) Key Eng Mater 409:145

Bulpakdi P, Taskonak B, Yan J, Mecholsky JJ (2009) Dental Mater 25:634

Carpinteri A, Paggi M (2010) Int J Fract 161:41

Mecholsky JJ (2006) Mater Lett 60:2485

Carpinteri A, Pugno N, Puzzi S (2009) Chaos Solitons Fractals 39:1210

Spagnoli A (2004) Chaos Solitons Fractals 22:589

Tanaka M, Kimura Y, Oyama N, Kato R (2006) J Mater Sci 41:6181. doi:https://doi.org/10.1007/s10853-006-0176-7

Drummond JL, Thompson M, Super BJ (2005) Dental Mater 21:586

Della Bona A, Hill TJ, Mecholsky JJ (2001) J Mater Sci 36:2645. doi:https://doi.org/10.1023/A:1017948409986

Carpinteri A, Chiaia B, Invernizzi S (1999) Theor Appl Fract Mech 31:163

Zhou HW, Xie HP (2003) Surf Rev Lett 10:751

Tanaka M, Kimura Y, Kayama A, Taguchi J, Kato R (2005) J Mater Sci 40:6291. doi:https://doi.org/10.1007/s10853-005-3140-z

Ruzicka S, Hausild P (2010) Eng Fract Mech 77:744

Adachi K, Chung SH, Friedrich H, Buseck PR (2007) J Geophys Res 112:D14202. doi:https://doi.org/10.1029/2006JD8296

Elfallagh F, Inkson BJ (2009) J Eur Ceram Soc 29:47

Chang Q, Chen DL, Ru HQ, Yue XY, Yu L, Zhang CP (2010) Biomaterials 31:1493

Kruzic J, Ritchie RO (2003) J Am Ceram Soc 86:1433

ANSI/ASME B46.1-2002, Surface texture (Surface roughness, waviness and lay). American Society of Mechanical Engineers, 2002

Kruzic JJ, Satet RL, Hoffmann MJ, Cannon RM, Ritchie RO (2008) J Am Ceram Soc 91:1986

Kumar R, Prakash KH, Cheang P, Khor KA (2005) Acta Mater 53:2327

Mecholsky JJ, Mackin TJ (1988) J Mater Sci Lett 7:1145

Ritchie RO, Dauskardt RH, Yu W, Brendzel AM (1990) J Biomed Mater Res 24:189

Fett T, Munz D (2006) Arch Appl Mech 76:667

Ponton CB, Rawlings RD (1989) Mater Sci Tech 5:865

Scherrer SS, Denry IL, Wiskott HWA (1998) Dental Mater 14:246

Kruzic JJ, Ritchie RO (2004) Ceramic Transactions 156:83

Gatto A (2006) J Mater Proc Tech 174:67

Denry IL, Holloway JA (2004) Dental Mater 20:213

Imbeni V, Kruzic JJ, Marshall GW, Marshall SJ, Ritchie RO (2005) Nat Mater 4:229

Merkel I, Messerschmidt U (1992) Mater Sci Eng A 151:131

Acknowledgements

The authors would like to thank the financial support of Natural Sciences and Engineering Research Council of Canada (NSERC). Q.C. is also to acknowledge the financial support provided by China Scholarship Council and the Fundamental Research Funds for the Central Universities (N090602001) and D.L.C. is also grateful for the financial support by the Premier’s Research Excellence Award (PREA), Canada Foundation for Innovation (CFI), and Ryerson Research Chair (RRC) program. The authors would also like to thank Q. Li, A. Machin, J. Amankrah and R. Churaman for their assistance in the experiments. Professor N. Zhang is also gratefully acknowledged for her continuous encouragement while performing this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, Q., Chen, D.L., Ru, H.Q. et al. Three-dimensional fractal analysis of fracture surfaces in titanium–iron particulate reinforced hydroxyapatite composites: relationship between fracture toughness and fractal dimension. J Mater Sci 46, 6118–6123 (2011). https://doi.org/10.1007/s10853-011-5576-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5576-7