Abstract

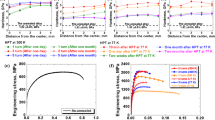

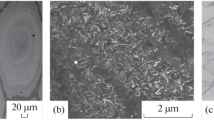

The process of high-pressure torsion (HPT) was applied to control the size and distribution of ferromagnetic Co particles in a Cu–Co alloy. Electron probe microanalysis, X-ray diffraction analysis, and transmission electron microscopy confirmed that the Co particles were significantly refined through fragmentation and dissolved with intense straining by HPT. Magnetoresistance appeared by ~2.5% at 77 K with an isotropic feature corresponding to giant magnetoresistance (GMR). It is demonstrated that HPT is a potential process for creating GMR in the Cu–Co alloy prepared by conventional ingot metallurgy.

Similar content being viewed by others

References

Berkowitz AE, Mitchell JR, Carey MJ, Young AP, Zhang S, Spada FE et al (1992) Phys Rev Lett 68:3745. doi:https://doi.org/10.1103/PhysRevLett.68.3745

Xiao JQ, Jiang JS, Chien CL (1992) Phys Rev Lett 68:3749. doi:https://doi.org/10.1103/PhysRevLett.68.3749

Takanashi K, Park J, Sugawara T, Hono K, Goto A, Yasuda H et al (1996) Thin Solid Films 275:106. doi:https://doi.org/10.1016/0040-6090(95)07064-8

Wang W, Zhu F, Weng J, Xiao J, Lai W (1998) Appl Phys Lett 72:1118. doi:https://doi.org/10.1063/1.120942

Kim IJ, Takeda H, Echigoya J, Kataoka N, Fukamichi K, Shimada Y (1996) Mater Sci Eng A 217–218:363. doi:https://doi.org/10.1016/S0921-5093(96)10347-6

Aizawa T, Zhou C (2000) Mater Sci Eng A 285:1. doi:https://doi.org/10.1016/S0921-5093(00)00709-7

Larde R, Le Breton JM (2005) J Magn Magn Mater 290:1120. doi:https://doi.org/10.1016/j.jmmm.2004.11.471

Rattanasakulthong W, Sirisathitkul C (2005) Physica B 369:160. doi:https://doi.org/10.1016/j.physb.2005.08.010

Massalski TB, Murray JL, Bennett LH, Baker H, Kacprzak L (1987) Binary phase diagrams, vol 1. American Society of Metals, Metals Park, OH, p 758

Rentenberger C, Karnthaler HP (2005) Acta Mater 53:3031. doi:https://doi.org/10.1016/j.actamat.2005.03.016

Waitz T, Kazykhanov V, Karnthaler HP (2004) Acta Mater 52:137. doi:https://doi.org/10.1016/j.actamat.2003.08.036

Sabirov I, Pippan R (2005) Scr Mater 52:1293. doi:https://doi.org/10.1016/j.scriptamat.2005.02.017

Kai M, Horita Z, Langdon TG (2008) Mater Sci Eng A 488:117

Senkov ON, Froes FH, Stolyarov VV, Valiev RZ, Liu J (1998) Nanostruct Mater 10:691. doi:https://doi.org/10.1016/S0965-9773(98)00107-X

Sauvage X, Wetscher F, Pareige P (2005) Acta Mater 53:2127

Sakai G, Horita Z, Langdon TG (2005) Mater Sci Eng A 393:344. doi:https://doi.org/10.1016/j.msea.2004.11.007

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) JOM 58(4):33. doi:https://doi.org/10.1007/s11837-006-0213-7

Segal VM, Reznikov VI, Drobyshevskiy AE, Kopylov VI (1981) Russ Metall 1:99

Saito Y, Utsunomiya H, Tsuji N, Sakai T (1999) Acta Mater 47:579. doi:https://doi.org/10.1016/S1359-6454(98)00365-6

Dutkiewicz J, Kuśnierz J, Maziarz W, Lejkowska M, Garbacz H, Lewandowska M et al (2005) Phys Status Solidi 202:2309. doi:https://doi.org/10.1002/pssa.200521235

Stolyarov VV, Gunderov DV, Popov AG, Puzanova TZ, Raab GI, Yavari AR et al (2002) J Magn Magn Mater 242–245:1399. doi:https://doi.org/10.1016/S0304-8853(01)01244-6

Vorhauer A, Rumpf K, Granitzer P, Kleber S, Krenn H, Pippan R (2006) Mater Sci Forum 503–504:299

Suehiro K, Nishimura S, Horita Z (2008) Mater Trans 49:102. doi:https://doi.org/10.2320/matertrans.ME200725

Servi IS, Turnbull D (1966) Acta Metall 14:161. doi:https://doi.org/10.1016/0001-6160(66)90297-5

Fujii T, Tamura T, Kato M, Onaka S (2002) Microsc Microanal 8(Suppl. 2):1434CD

Suryanarayana C (2001) Prog Mater Sci 46:1. doi:https://doi.org/10.1016/S0079-6425(99)00010-9

Acknowledgements

This work was supported in part by a Grant-in-Aid for Scientific Research from the Ministry of Education, Culture, Sports, Science and Technology, Japan, in Priority Areas “Giant Straining Process for Advanced Materials Containing Ultra-High Density Lattice Defects” and in part by Kyushu University Interdisciplinary Programs in Education and Projects in Research Development (P&P).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suehiro, K., Nishimura, S., Horita, Z. et al. High-pressure torsion for production of magnetoresistance in Cu–Co alloy. J Mater Sci 43, 7349–7353 (2008). https://doi.org/10.1007/s10853-008-2813-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2813-9