Abstract

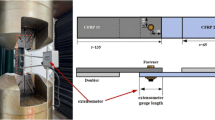

Carbon fibre reinforced polymers (CFRPs) are now well established in many high-performance applications and look set to see increased usage in the future, especially if lower cost manufacturing and solutions to certain technical issues, such as poor out-of-plane strength, can be achieved. A significant question when manufacturing with CFRP is the best joining technique to use, with adhesive bonding and mechanical fastening currently the two most popular methods. It is a common view that mechanical fastening is preferred for thicker sections and adhesive bonding for thinner ones; however, advances in the technology and better understanding of ways to design joints have lead to increasing consideration of adhesive bonding for traditionally mechanically fastened joints. In high-performance applications fatigue loading is likely and in some cases repetitive low-energy impacts, or impact fatigue, can appear in the load spectrum. This article looks at mixed-mode crack growth in epoxy bonded CFRP joints in standard and impact fatigue. It is shown that the back-face strain technique can be used to monitor cracking in lap-strap joints (LSJs) and piezo strain gauges can be used to measure the strain response of impacted samples. It is seen that there is significant variation in the failure modes seen in the samples and that the crack propagation rate is highly dependent on the fracture mode. Furthermore, it is found that the crack propagation rate is higher in impact fatigue than in standard fatigue even when the maximum load is significantly lower.

Similar content being viewed by others

References

Cantwell W, Curtis PT, Morton J (1983) Composites 14:301. doi:https://doi.org/10.1016/0010-4361(83)90020-4

Ramkumar RL (1983) Effect of low-velocity impact damage on the fatigue behaviour of graphite/epoxy laminates. In: O’Brien TK (ed) Long term behaviour of composites, ASTM STP 813, ASTM, Philadelphia, pp 116–135

Clark G, Saunders DS (1991) Mater Forum 15:333

Ray D, Sarkar BK, Bose NR (2002) Comp A 33:233. doi:https://doi.org/10.1016/S1359-835X(01)00096-3

Khan B, Rao RMVGK, Venkataraman N (1994) J Reinf Plast Comp 14:1150

Sinmmazçelik T, Armağan A (2006) J Mater Sci A 41(19):6237. doi:https://doi.org/10.1007/s10853-006-0720-5

Davies P (2005) Bonding of composites. In: Adams RD (ed) Adhesive bonding: science, technology and applications. Woodhead Publishing, Cambridge, pp 279–301

Tong L, Steven GP (1999) Analysis and design of structural bonded joints. Kluwer Academic Publishing, London

Adams RD, Comyn J, Wake WC (1997) Structural adhesive joints in engineering, 2nd edn. Chapman and Hall, London

Hart-Smith LJ (2002) J Compos Tech Res 24:133

Ashcroft IA, Hughes DJ, Shaw SJ (2000) Assembly Autom 20:150. doi:https://doi.org/10.1108/01445150010321797

Ashcroft IA, Hughes DJ, Shaw SJ (2001) Int J Adhes Adhes 21:87. doi:https://doi.org/10.1016/S0143-7496(00)00038-5

Schön J, Starikov R (2000) Fatigue of joints in composites structures. In: Harris B (ed) Fatigue in composites. Woodhead Publishing Limited, Cambridge, pp 621–643

Mall S, Ramamurthy G, Rezaizdeh MA (1987) Compos Struct 8:31. doi:https://doi.org/10.1016/0263-8223(87)90014-6

Ashcroft IA, Abdel Wahab MM, Crocombe AD, Hughes DJ, Shaw SJ (2001) J Adhesion 75:61. doi:https://doi.org/10.1080/00218460108029594

Ashcroft IA (2004) J Strain Anal 39:707. doi:https://doi.org/10.1243/0309324042379239

Sato C (2005) Impact behaviour of adhesively bonded joints. In: Adams RD (ed) Adhesive bonding: science, technology and applications. Woodhead Publishing, Cambridge, pp 164–187

Beevers A, Ellis MD (1984) Int J Adhes Adhes 4(1):13. doi:https://doi.org/10.1016/0143-7496(84)90055-1

Kihara K, Isono H, Yamabe H, Sugibayashi T (2003) Int J Adhes Adhes 23:253. doi:https://doi.org/10.1016/S0143-7496(03)00004-6

Adams RD, Harris JA (1996) Int J Adhes Adhes 16:61. doi:https://doi.org/10.1016/0143-7496(95)00050-X

Yokoyama T (2003) J Strain Anal 38(3):233. doi:https://doi.org/10.1243/030932403765310563

Usui Y, Sakata O (1984) Jpn Soc Proc Eng 18(3):213

Casas-Rodriguez JP, Ashcroft IA, Silberschmidt VV (2007) Int J Sound Vib 308:467. doi:https://doi.org/10.1016/j.jsv.2007.03.088

Casas-Rodriguez JP, Ashcroft IA, Silberschmidt VV (2007) Compos Sci Technol. doi:https://doi.org/10.1016/j.compscitech.2008.04.030

Casas-Rodriguez JP, Ashcroft IA, Silberschmidt VV (2008) Compos Sci Technol. doi:https://doi.org/10.1016/j.compscitech.2007.11.006

Brussat TR, Chiu ST, Mostvoy S (1977) Fracture mechanics for structural adhesive bonds—final report, AFML-TR-77-163, Air Force Materials Laboratory, Wright Patterson Air Force Base, Dayton, OH

Sethuraman R, Maiti SK (1988) Eng Fract Mech 30:227. doi:https://doi.org/10.1016/0013-7944(88)90226-3

Rice JR (1968) J Appl Mech 35:379

Ashcroft IA, Abdel Wahab MM, Crocombe AD, Hughes DJ, Shaw SJ (2001) Compos Part A 32:45. doi:https://doi.org/10.1016/S1359-835X(00)00131-7

Abdel Wahab MM, Ashcroft IA, Crocombe AD, Hughes DJ, Shaw SJ (2001) Compos Part A 32:59. doi:https://doi.org/10.1016/S1359-835X(00)00132-9

Ashcroft IA (2005) Fatigue. In: Adams RD (ed) Adhesive bonding: science, technology and applications. Woodhead Publishing, Cambridge, pp 209–237

Schijve J (2001) Fatigue of structures and materials. Kluwer Academic, London

Paris PC, Erdogan F (1963) Trans ASME D 85:528

Ashcroft IA, Shaw SJ (2002) Int J Adhes Adhes 22:151. doi:https://doi.org/10.1016/S0143-7496(01)00050-1

Acknowledgement

The authors are very grateful for a partial financial support by the Royal Society within the framework of its International Joint Projects scheme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ashcroft, I.A., Casas-Rodriguez, J.P. & Silberschmidt, V.V. Mixed-mode crack growth in bonded composite joints under standard and impact-fatigue loading. J Mater Sci 43, 6704–6713 (2008). https://doi.org/10.1007/s10853-008-2646-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2646-6