Abstract

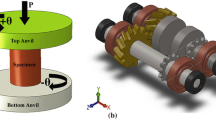

Tests were conducted on an Al-6061 alloy to evaluate the separate effects of the applied pressure and the torsional straining in processing by high-pressure torsion (HPT). The values of the Vickers microhardness were measured after processing and plotted both linearly across the diameters of the disks and as three-dimensional representations. The measurements show that the applied pressure increases the hardness in the absence of torsional straining. In the presence of a pressure and torsional straining, the hardness values are high at the edges of the disk but lower in the central region. There is a gradual evolution toward a hardness homogeneity with increasing numbers of HPT revolutions. The hardness values at the edges of the disks are reasonably independent of the applied pressure but the extent of this region of high hardness depends upon both the applied pressure and the numbers of turns in the HPT processing.

Similar content being viewed by others

References

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103. doi:https://doi.org/10.1016/S0079-6425(99)00007-9

Valiev RZ, Langdon TG (2006) Prog Mater Sci 51:881. doi:https://doi.org/10.1016/j.pmatsci.2006.02.003

Zhilyaev AP, Nurislamova GV, Kim BK, Baró MD, Szpunar JA, Langdon TG (2003) Acta Mater 51:753. doi:https://doi.org/10.1016/S1359-6454(02)00466-4

Stolyarov VV, Valiev RZ (2004) In: Zehetbauer MJ, Valiev RZ (eds) Nanomaterials by severe plastic deformation. Willey-VCH, Weinheim, p 125

Zhilyaev AP, Kim BK, Nurislamova GV, Baró MD, Szpunar JA, Langdon TG (2002) Scripta Mater 48:575

Zhilyaev AP, Oh-Ishi K, Langdon TG, McNelley TR (2005) Mater Sci Eng A410–A411:277. doi:https://doi.org/10.1016/j.msea.2005.08.044

Valiev RZ, Ivanisenko YuV, Rauch EF, Baudelet B (1996) Acta Mater 44:4705. doi:https://doi.org/10.1016/S1359-6454(96)00156-5

Wetscher F, Vorhauer A, Stock R, Pippan A (2004) Mater Sci Eng A387–A389:809. doi:https://doi.org/10.1016/j.msea.2004.01.096

Zhilyaev AP, Lee S, Nurislamova GV, Valiev RZ, Langdon TG (2001) Scripta Mater 44:2753. doi:https://doi.org/10.1016/S1359-6462(01)00955-1

Sakai G, Horita Z, Langdon TG (2005) Mater Sci Eng A393:344. doi:https://doi.org/10.1016/j.msea.2004.11.007

Horita Z, Langdon TG (2005) Mater Sci Eng A410–A411:422. doi:https://doi.org/10.1016/j.msea.2005.08.133

Xu C, Horita Z, Langdon TG (2007) Acta Mater 55:203. doi:https://doi.org/10.1016/j.actamat.2006.07.029

Jiang H, Zhu YT, Butt DP, Alexandrov IV, Lowe TC (2000) Mater Sci Eng A290:128. doi:https://doi.org/10.1016/S0921-5093(00)00919-9

Vorhauer A, Pippan R (2004) Scripta Mater 51:921. doi:https://doi.org/10.1016/j.scriptamat.2004.04.025

Yang Z, Welzel U (2005) Mater Lett 59:3406. doi:https://doi.org/10.1016/j.matlet.2005.05.077

Xu C, Furukawa M, Horita Z, Langdon TG (2005) Mater Sci Eng A398:66. doi:https://doi.org/10.1016/j.msea.2005.03.083

Xu C, Langdon TG (2007) J Mater Sci 42:1542. doi:https://doi.org/10.1007/s10853-006-0899-5

Zhilyaev AP, McNelley TR, Langdon TG (2007) J Mater Sci 42:1517. doi:https://doi.org/10.1007/s10853-006-0628-0

Todaka Y, Umemoto M, Yamazaki A, Sasaki J, Tsuchiya K (2008) Mater Trans 49:7. doi:https://doi.org/10.2320/matertrans.ME200713

Čížek J, Procházka I, Brauer G, Anwand W, Kužel R, Cieslar M, Islamgaliev RK (2003) Phys Stat Sol A 195:335. doi:https://doi.org/10.1002/pssa.200305929

Degtyarev MV, Chashchukhina TI, Voronova LM, Patselov AM, Pilyugin VP (2007) Acta Mater 55:6039. doi:https://doi.org/10.1016/j.actamat.2007.04.017

Ungár T, Balogh L, Zhu YT, Horita Z, Xu C, Langdon TG (2007) Mater Sci Eng A444:153. doi:https://doi.org/10.1016/j.msea.2006.08.059

Balogh L, Ungár T, Zhao Y, Zhu YT, Horita Z, Xu C, Langdon TG (2008) Acta Mater 56:809

Todaka Y, Umemoto M, Yamazaki A, Sasaki J, Tsuchiya K (2008) Mater Trans 49:47. doi:https://doi.org/10.2320/matertrans.ME200714

Concustell A, Sort J, Suriñach S, Gebert A, Eckert J, Zhilyaev AP, Baró MD (2007) Intermetallics 15:1038. doi:https://doi.org/10.1016/j.intermet.2006.12.009

Kovács Zs, Hóbor S, Szabó PJ, Lendvai J, Zhilyaev AP, Révész Á (2007) Mater Sci Eng A449–A451:1139. doi:https://doi.org/10.1016/j.msea.2006.03.133

Valiev RZ, Alexandrov IV, Zhu YT, Lowe TC (2002) J Mater Res 17:5

Acknowledgements

This work was supported in part by the Light Metals Educational Foundation of Japan, in part by a Grant-in-Aid for Scientific Research from the Ministry of Education, Culture, Sports, Science and Technology, Japan, in the Priority Area “Giant Straining Process for Advanced Materials Containing Ultra-High Density Lattice Defects” and in part by the National Science Foundation of the United States under Grant no. DMR-0243331.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, C., Horita, Z. & Langdon, T.G. Evaluating the influence of pressure and torsional strain on processing by high-pressure torsion. J Mater Sci 43, 7286–7292 (2008). https://doi.org/10.1007/s10853-008-2624-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2624-z