Abstract

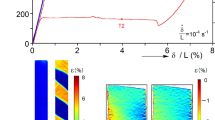

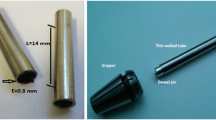

A three-dimensional micromechanical model for pseudoelasticity is implemented into ABAQUS to study the mechanical behavior of a polycrystalline NiTi shape memory alloy under biaxial loading. The model is firstly validated by numerical method and then used to simulate a thin-wall tube under non-proportional extension-torsion loading. When the tensile strain remains constant, the tensile stress decreases with increasing of the shear strain. While unloading the shear strain, the tensile stress increases. This is consistent with experimental results. The model can be used to get an idea of the pseudoelastic behavior of NiTi alloys under complex stress states.

Similar content being viewed by others

References

Liu Y, Xie ZL, Humbeeck JV (1999) Mater Sci Eng A 273:673

Besseghini S, Villa E, Tuissi A (1999) Mater Sci Eng A 273:390

Mckelvey AL, Ritchie RO (2001) Metal Mater Trans A 32:731

Gall K, Sehitoglu H, Anderson R et al (2001) Mater Sci Eng A 317:85

Gong JM, Tobushi H (2002) J Function Mater 33:391

McNaney JM, Imbeni V, Jung Y (2003) Mech Mater 35:969

Sawaguchi T, Kaustrater G, Yawny A et al (2003) Metal Mater Trans A 34:2847

Michutta J, Carroll MC, Yawny A, et al (2004) Mater Sci Eng A 378:152

Nemat-Nasser S, Choi JY, Guo WG, et al (2005) Mech Mater 37:287

Tanaka K, Kobayashi S, Sato Y (1986) Int J Plas 2:59

Tanaka K (1990) J Pres Ves Technol 112:158

Liang C, Rogers CA (1990) J Intell Mater Syst Struct 1:207

Lubliner J, Auricchio F (1996) Int J Solid Struct 33:991

Auricchio F, Sacco E (1997) Int J Non-linear Mech 32:1101

Auricchio F, Taylor RL, Lubliner J (1997) Comput Method Appl Mech Eng 146:281

Auricchio F, Sacco E (2001) Int J Solid Struct 38:6123

Auricchio F, Marfia S, Sacco E (2003) Comput Struct 81:2301

Yue ZF, Wan JS, Zhang QM (2003) Rare Met Mater Eng 32:246

Yan WY, Wang CH, Zhang XP, et al (2002) Smart Mater Struct 11:947

Wang XM, Wang YF, Baruj A et al (2005) Mater Sci Eng A 394:393

Patoor E, Eberhardt A, Berveiller M (1996) J de Phys IV 6:227

Huang M, Brinson LC, J Mech Phys Solids 97, 96, 1379

Gao X, Huang M, Brinson LC (2000) J Plast 16:1345

Thamburaja P, Anand L (2002) Int J Plast 18:1607

Gall K, Sehitoglu H (1999) Int J Plast 15:69

Gall K, Lim TJ, McDowell DL, et al (2000) Int J Plast 16:1189

Lim TJ, McDowell DL (2002) J Mech Phys Solids 50:651

ABAQUS UMAT Subroutine, ABAQUS/Standard User’s Manual, Vol. III, Hibbitt, Karlsson and Sorensen, Pawtucket, USA, 2001. 23.2.29

Acknowledgements

This work is supported by Deutsche Forschungsgemeinschaft SFB 459, Sino-German Project GZ050/1 and the Doctorate Foundation of Northwestern Polytechnical University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Frotscher, M., Wang, Y. et al. Finite element analysis of pseudoelastic behavior of NiTi shape memory alloy with thin-wall tube under extension-torsion loading. J Mater Sci 42, 2443–2449 (2007). https://doi.org/10.1007/s10853-006-1223-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1223-0